Sometime around 2006/2007 I initially fitted the Traction Avant with a CTA 6 volt alternator.

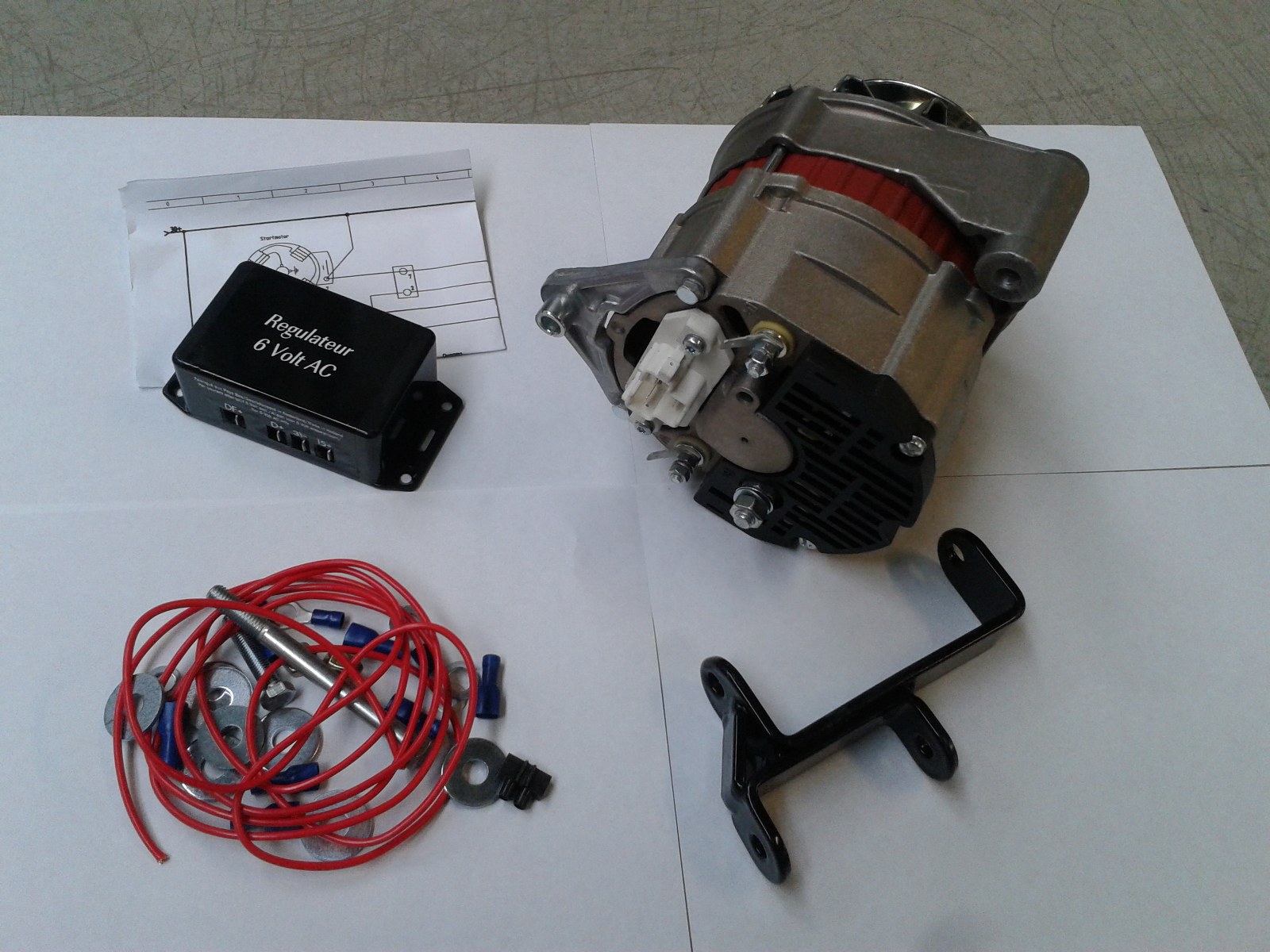

Above you see the CTA kit that I originally used to convert the 6 Volt system from DC to AC. You can also see the alternator from CTA installed at the time, the bracket from CTA never really worked well and seemed to be on the weak side.

Shortly after that I converted the car to 12 Volts.

I then replaced the regulator from the 6Volt type to a 12 Volt separate regulator.

That never really worked well. The charging current seemed reasonable but the voltage never rose above 12.4 Volts.

While a full battery when charged is at about 13.4 Volts.

After a lot of research and searching, I put a fixed regulator on the alternator, but that didn’t help either.

Now it seems that the field winding just can’t handle more because this alternator is wound for 6 Volts.

Seems strange to me, if you turn faster you get more voltage according to the Faraday book, but there also seems to be a saturation of the ironwork.

Later again, I converted the Traction to a 4-speed, with an ID19P engine and corresponding drive pulley for the water pump and alternator.

So in the end I just bought a new 12 (14) Volt alternator from ISKRA, actually a Mahle one.

This alternator delivers 14 Volt max and 33 Ampere max.

It still needed some modifications, of course a new bracket…

And the pulley had to be moved a little on the shaft.

I moved the big ring on the outside to the inside, behind the pulley and with that the offset was sufficient.

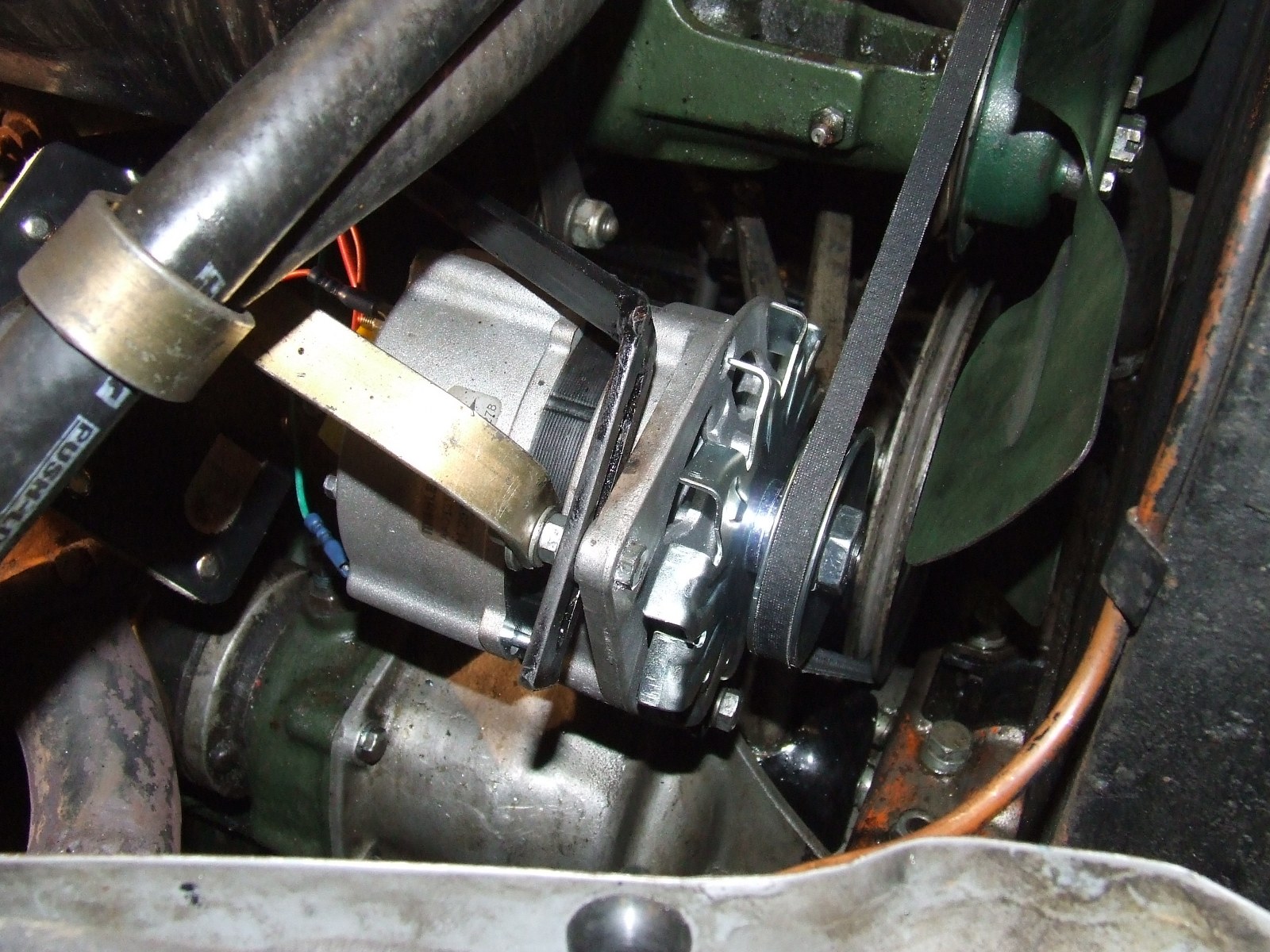

I found the bracket of the CTA set-up too weak, I had already replaced it for a sturdier home-made type.

The ISKRA alternator fits exactly in this bracket and further connection is no problem at all.

I have already converted my pulleys to thin belt dimensions of 10 mm because I was stuck to the pulley of the ID19P, which I wanted to keep because it is a bit larger than that of the original Traction Avant. This makes the water pump run just 5% faster and that seemed a good idea in connection with possible extra heat development from the ID19P engine, it was of course also the original pulley from that type of engine and it all just fitted with the engine mounting in the Traction Avant…

It remains to be seen, because the water pump of the TA is slightly different than that of the iD19P. It all works fine though.

The new alternator also works perfectly and charges the battery at 13.4 Volts.

In the end I did some calculations on the RPM’s you need to get a good charge.

From the graphs of this ISKRA alternator you can see that it only does something above 1200 RPM up to 7500 RPM.

The ID engine makes 650 RMM at idle up to max 3800 RPM.

The camshaft turns half the speed of the crankshaft so 325-1900 RPM.

The camshaft pulley of the ID19P is 21cm in diameter and that of the Dynamo is 7cm in diameter, this gives an acceleration of exactly 3x.

The shaft rotation speed of the dynamo is therefore between 975 and 4700 RPM. That’s too little to charge anything at idle.

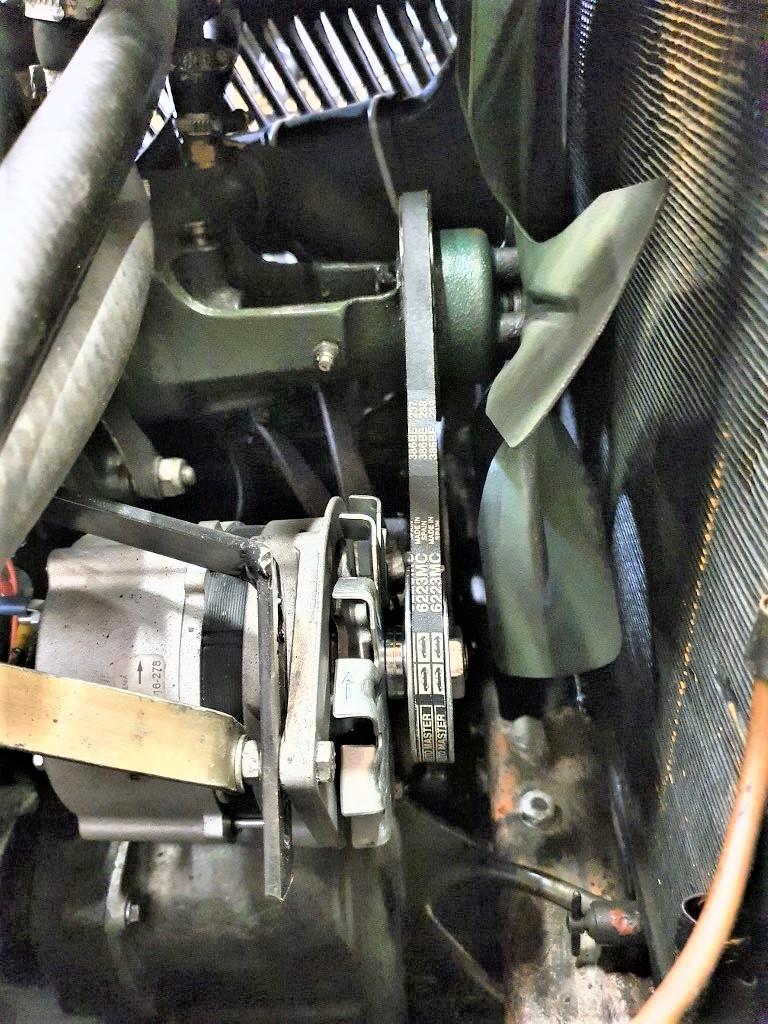

The pulley of an old DS20 alternator was turned from double pulley to single pulley by me earlier and was mounted on the CTA 6V alternator, see the photo higher in this article. This one has a diameter of 6cm. The acceleration from crankshaft pulley to dynamo is then 21/6=3.5x.

With this smaller dynamo pulley, the shaft rotation speed of the dynamo becomes 3.5 x(325-1900) RPM, so 1150-5650 RPM. That’s just enough to charge something at idle.

See below an action picture of the moving fan and pulley c.q. belt….

Switched DC-DC proportional inverters have been made and installed for all motors such as windshield wiper and heater. The bulbs have all been replaced for 12 Volt types and the signal driver has also been replaced. The fuel gauge ballast resistor has been modified, the air horn pump, and the starter motor have all been replaced for a 12 Volt type. Control lights, dash lights and so on have all been replaced as well. And… just a bit more about how it was with the DC alternator: