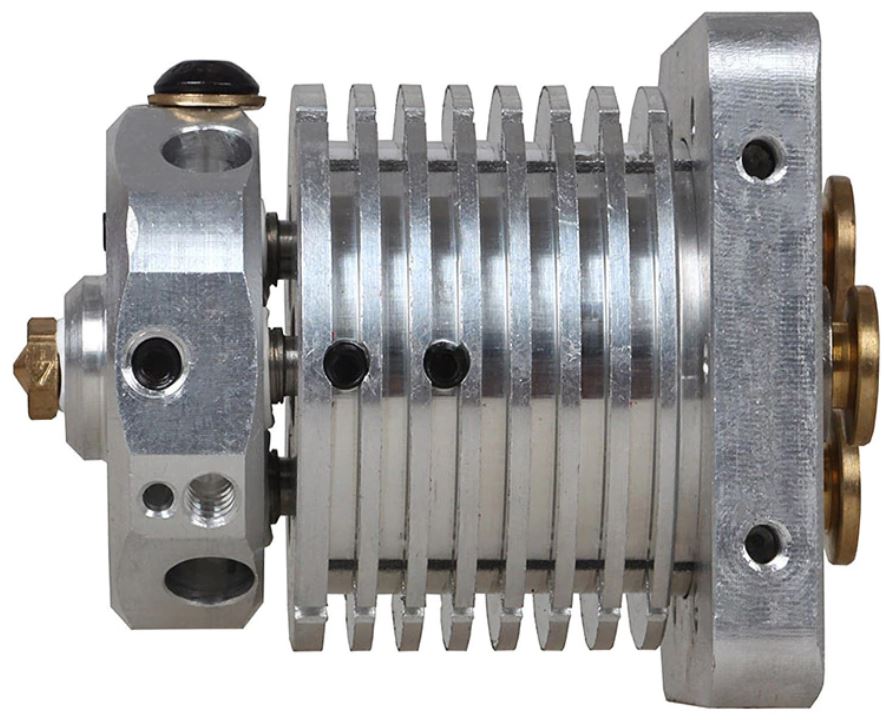

Today I received my 5-in, 1-out hotend, non-mixing air cooled with 1 nozzle and 1 heater//temp sensor.

I will install it on my A30M with the Duet2wifi board+extension board (5-fold with plug-in drivers). The A30M already has independant Z-stepper motors.

The Duet2wifi has 5 stepper ports, and the expansion board also has 5 stepper ports. X,Y,2xZ, 5 Extruders is a total of 9 so this will indeed fit!

I will make new wiring for the 5 extruder steppers on top of the A30M frame with 5 bowden tubes to the hotend. Since the hotend is non-mixing, this will be a simple task to get into config.g. For the slicer- it will also be easy. Just add the extruders to a total of 5 pieces. Add the correct filaments/temps/ no offset so set offset X and Y to 0.. The work will primarily be in the tool changing files for T0-T5 where retraction- and extruding settings will be needed.

For the hotend, I have a new setup available that allows me to quickly change the nozzle.

This will make it possible to use this setup for all kind of applications.