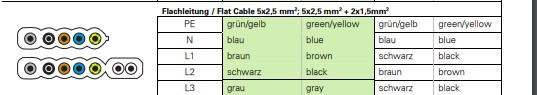

UPDATE 2025-05: We now have a flat 2.5mm2 x6 cable::

In this post we will describe our solution for charging Electric Vehicles from your home across the public pavement when using our super thin EV cable mat with rubber slabs.

Due to the rapidly growing ownership of electric cars, and the fact that roughly 60% of the Dutch population can not charge their car from within their own property, charging across public pavements has become an issue.

25% of Dutch City Councils is involved in pilot projects about all sorts of solutions to get the private energy-infrastructure used for charging ones own EV. But- there is no general regulation for this.

And- you really don’t want to get all sorts of different solutions for putting charging cables in the way of pedestrians, especially not when these solutions leave something in the way after it has been used. Certainly you don’t want to put anything in the way of people with baby walkers, playing children, people with disabilities, elderly or people that use mobility walkers.

Numerous solutions have been tested and there is not one solution that fits all.

Most promising appears to be the solution of a pavement gutter in which the charging cable can be pushed in, during charging. But- it has also proved to be difficult in practice since this only works well if no-one interferes with its usage. If the cable is pulled out, it will be in the way of everyone that needs to step over it.

In my mind, a simpler solution will be required by thinking unconventionally, typically out of the non-electric box

The problem is that we want to charge the car’s battery from our existing solar panels, we then want to make use of the EV’s battery for our home aplliances through the Vehicle to Load feature during the period that there is not enough sun to use the solar panels. Then, we can really close the energy circle without additional investments in home batteries and so on. That is what this is all intended for. Multi-use of the EV’s battery and of the available solar power.

BUT- this can only work with the EV’s battery connected to your home.

And the public pavement needs to be crossed.

One of the possibilities to do this could be by constructing a charging/Vehicle To Load cable that is flat enough to behave as a doormat on the pavement. This mat must be flat enough to not cause any interfecerence for pedestrians, walkers and so on BUT it must be tough enough to keep its form and electrical characteristics during its use.

In my view, the flat cable mat should have flat start- and ending docking cables, reshape to normal round cables and EV charging connectors, connecting to the EV’s charging port and the other end to the charging point at the home.

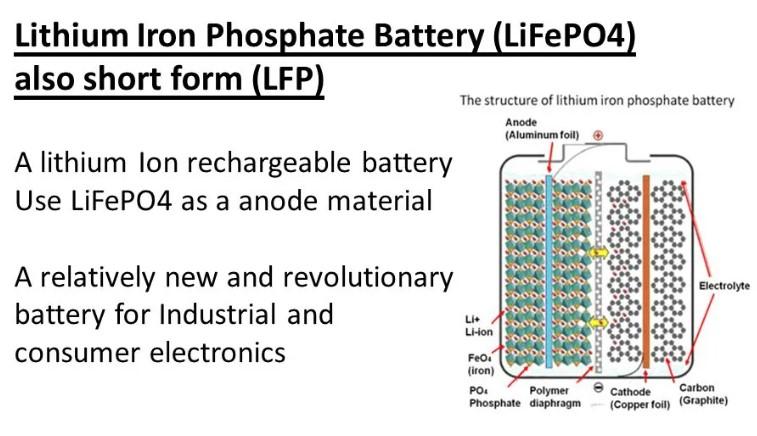

EV charging from A/C has a maximum power of 11kW, 3 phase 400 Volts.

The current will be 16 Ampères x3 lines and per line at least 2.5 mm2 is required.

Some insulation in between the wiring is regulatory required.

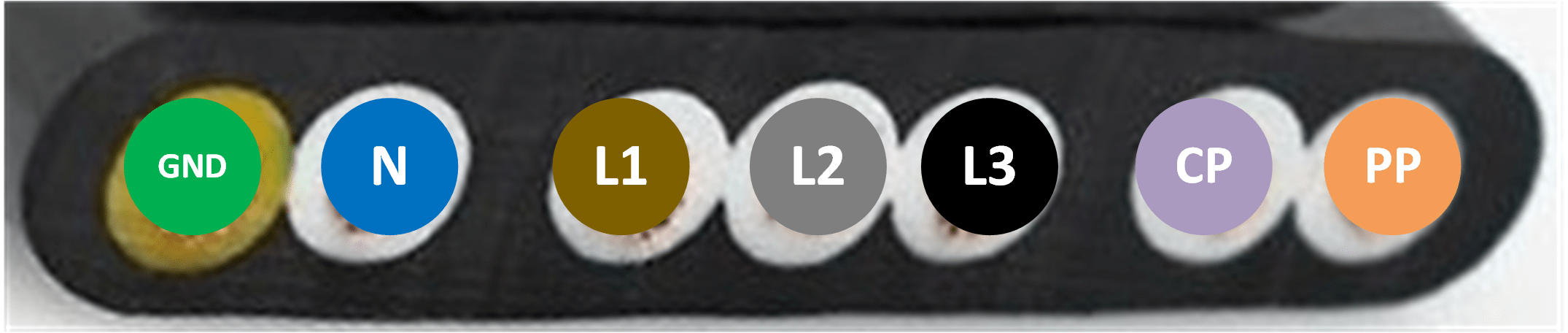

For the 2 management wires we will also use round wires.

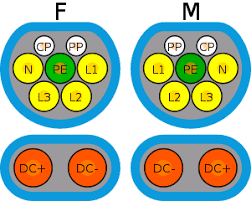

We will need 5×2.5mm2 and 2 control wires, a total of 7.

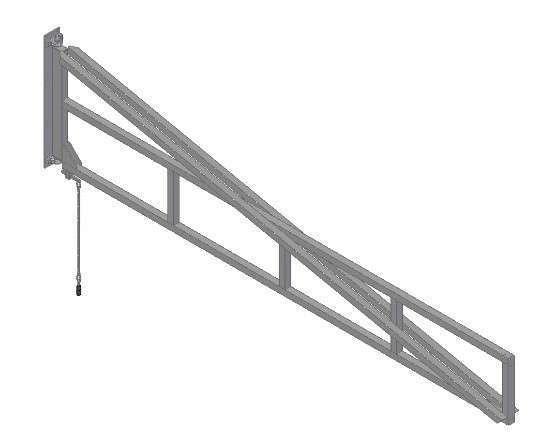

Standard flat elevator cable will be used of 7×2.5 mm2, see the below picture, the lowest one.

And- the mat will need to be wider than this, since we can use this to bring the height (thickness) back to 2-3 mm at the end of the mat’s side. That gives the look and usage experience that the EV cable mat is hardly in the way of the walking/rolling path.

Our ‘patent pending’ design of the Jantec.nl EV charging pavement cable mat:

Total width of the EV pavement cable mat is around 40 cm

The slab has the behaviour of a normal doormat. We will pour our rubberized mat around the center EV-cables part. The rubber will protect the cables and will also keep the EV cable mat flat on the pavement.

Cable center part is only 1,5-2 cm wide and only 5 mm high (thick)

The EV cable mat will become available in lengths of 1, 1.5 and 2 meters.

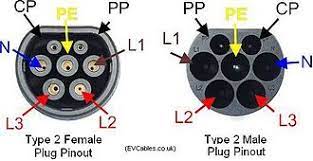

At both ends the copper wires are bound into a regular round cable with 2.5 meters of cable, including regular Mennekes a male and a female charging connector.

NB: The product is under evaluation 2022-10-29.

Pricing is yet unknown, but will be above Eur 300 per set.

For the time being, I used my old rubber mat that has a cut-out already, although the cable is clearly visible through he mat.

The flat cable is working much better!!