MORE E3D TOOLCHANGER POSTS

4xHemera direct drive first prints

Tuning the tool pickups with reprap global variables

X-and Y- axis homing switches installing and configuring

Hymera fans 2, 4, 6 and 8 intermittent problem solved

E3D 4-toolchanger 3D printer updates

Custom E3D toolchanger Dock adapter plate

Calibrating E3D coreXY 4-toolchanger 3d printer

multicolor gadget open hollow multicolor 3d printer designs

Toolhead stepper fault and solution

BUILDING MY MULTICOLOR E3D PRINTER

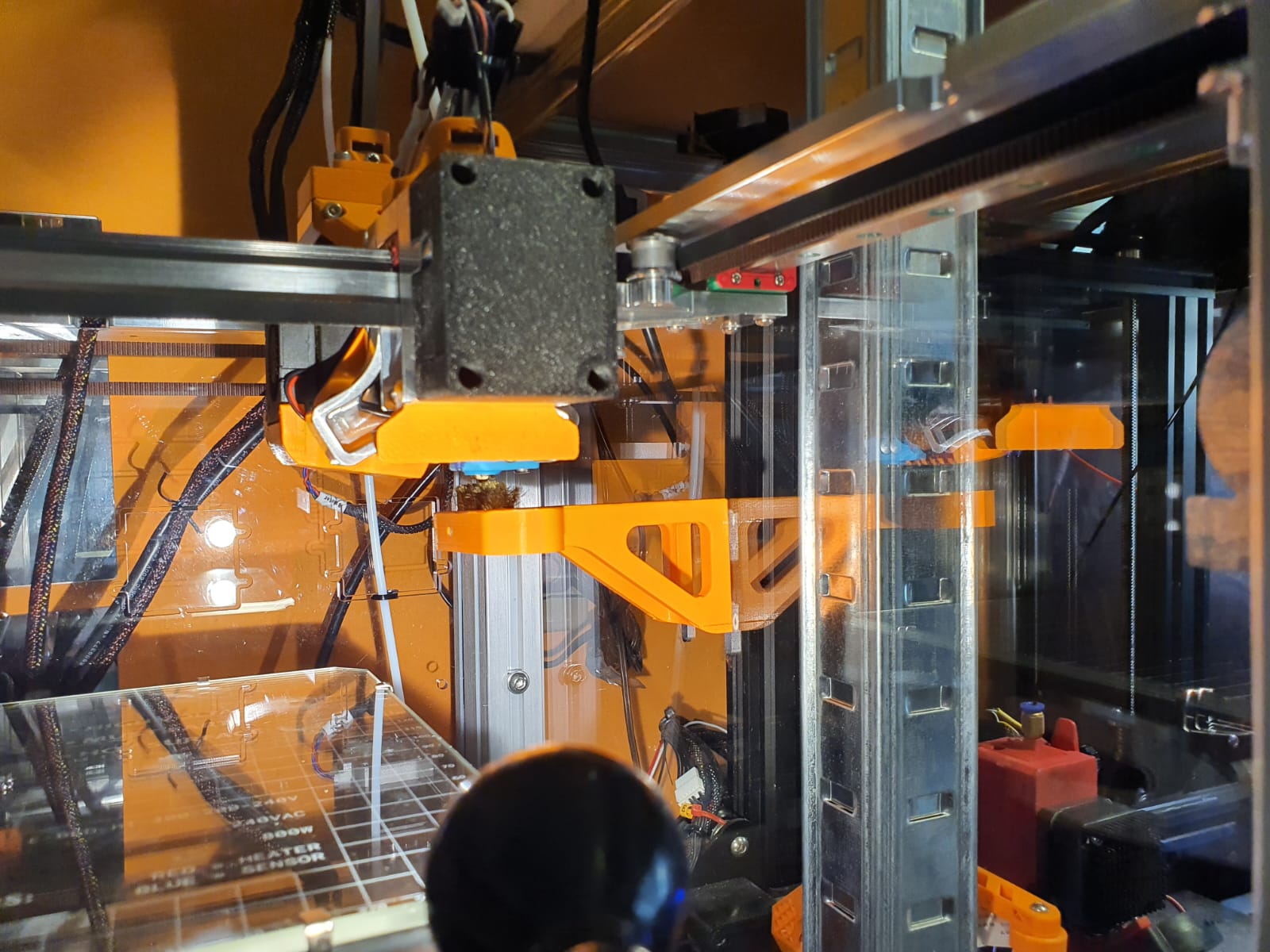

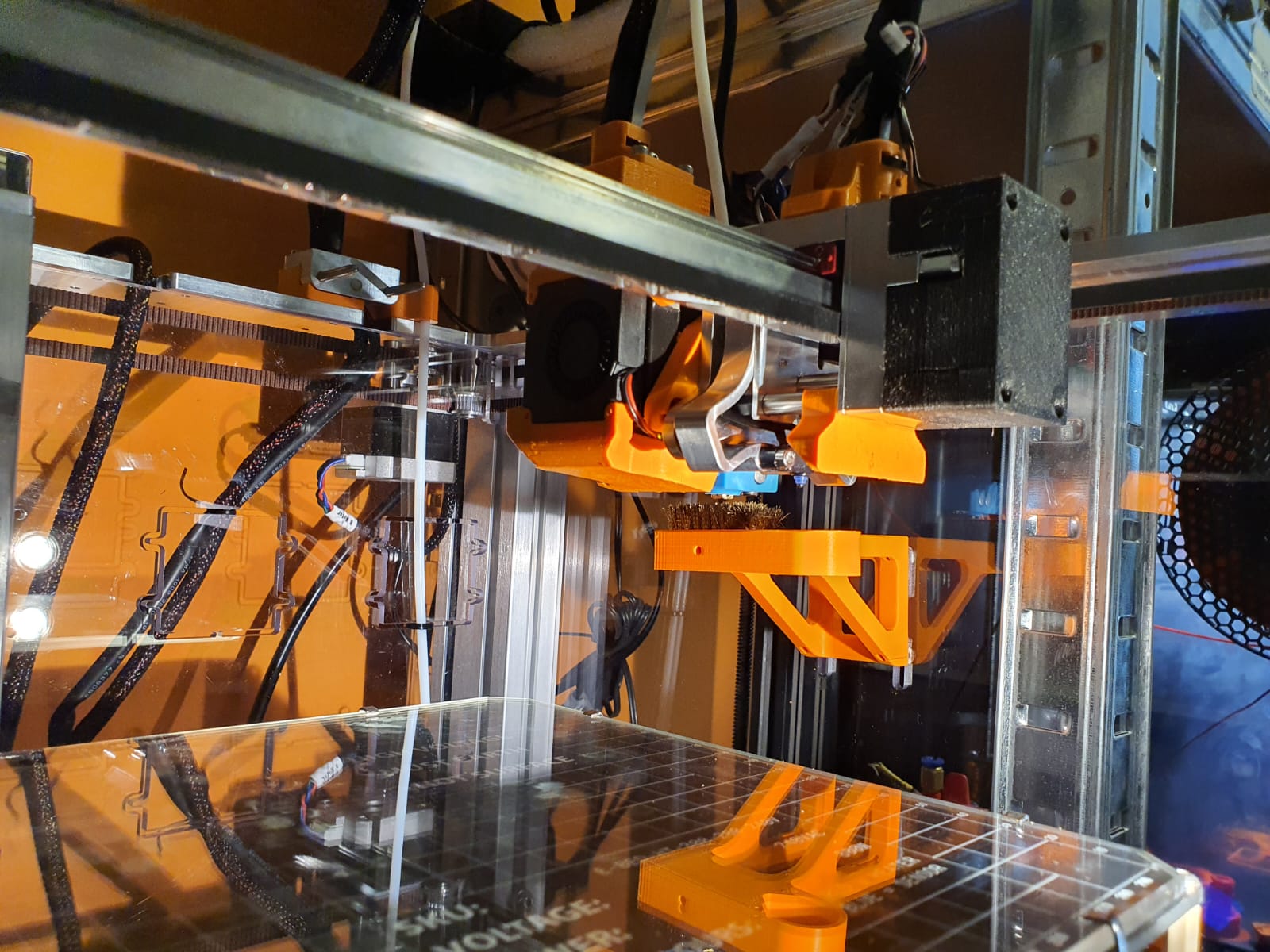

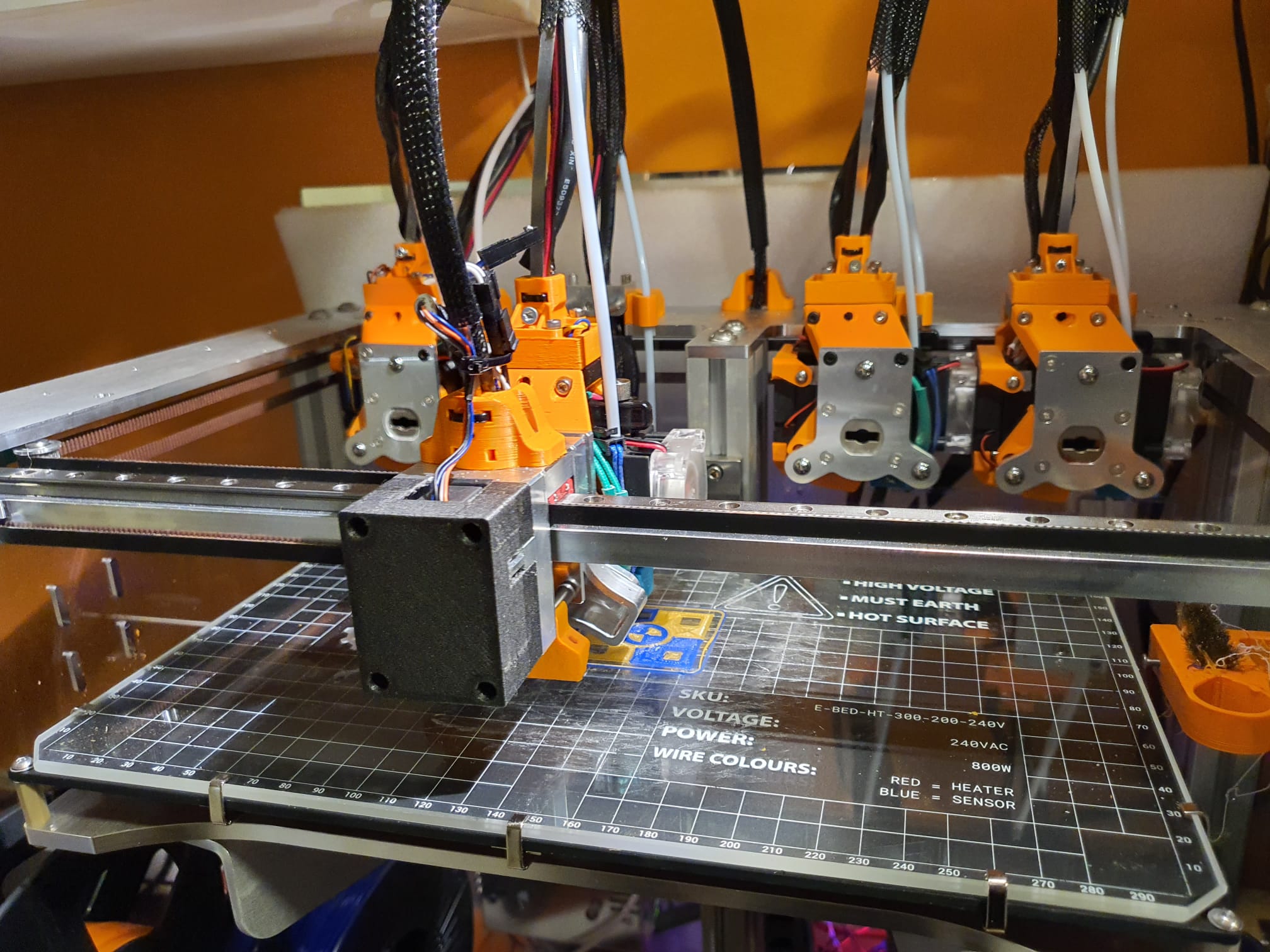

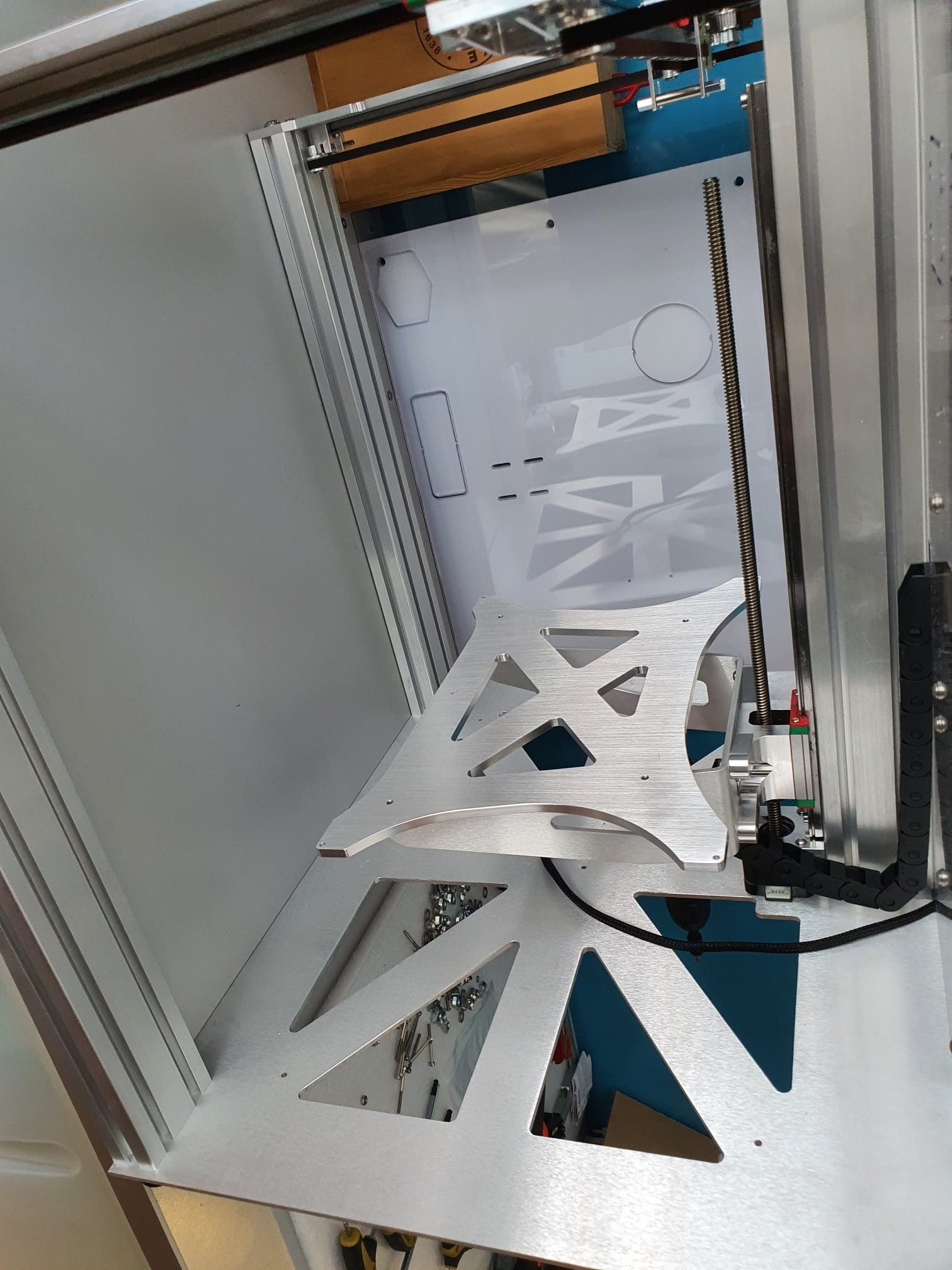

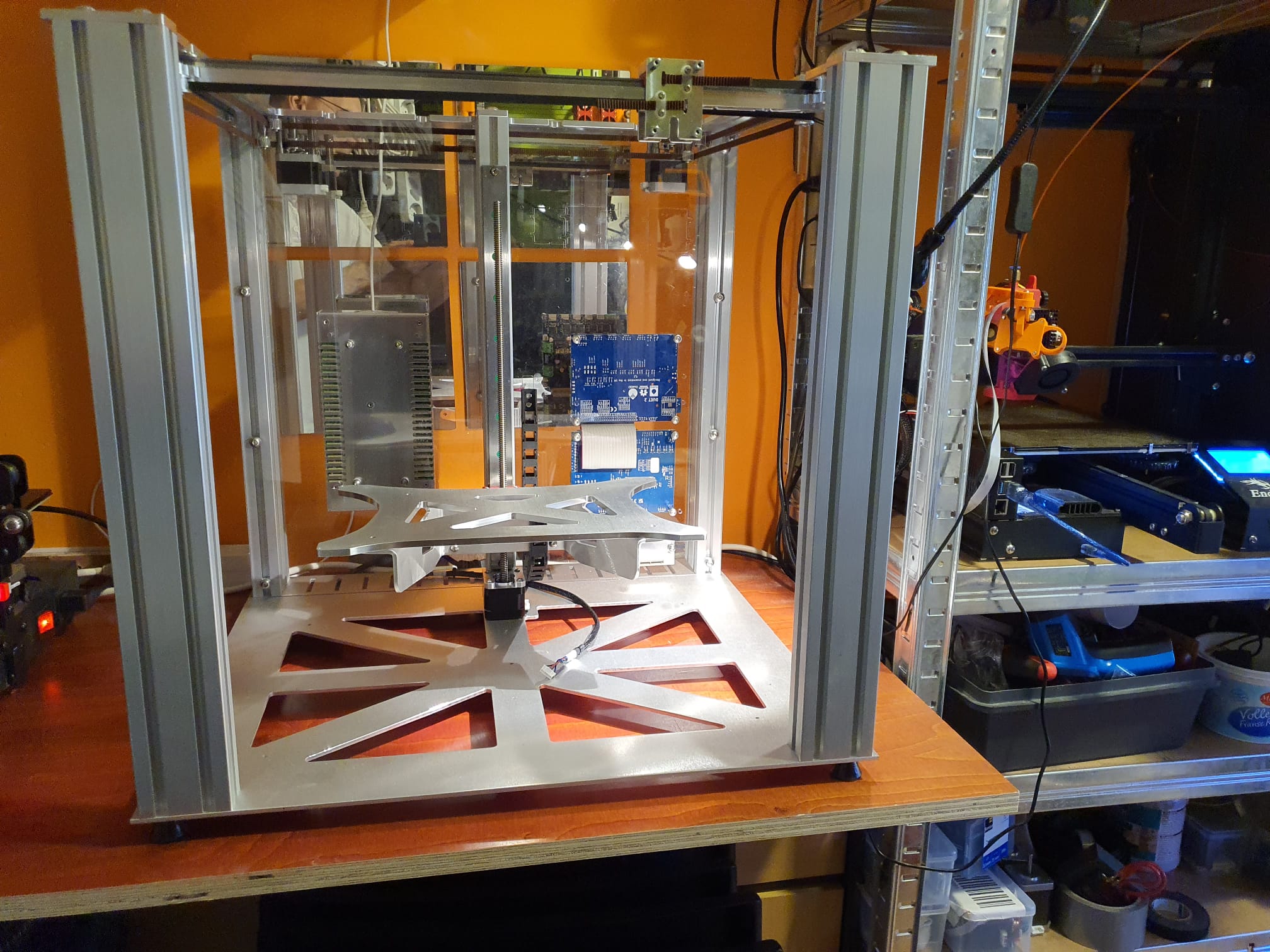

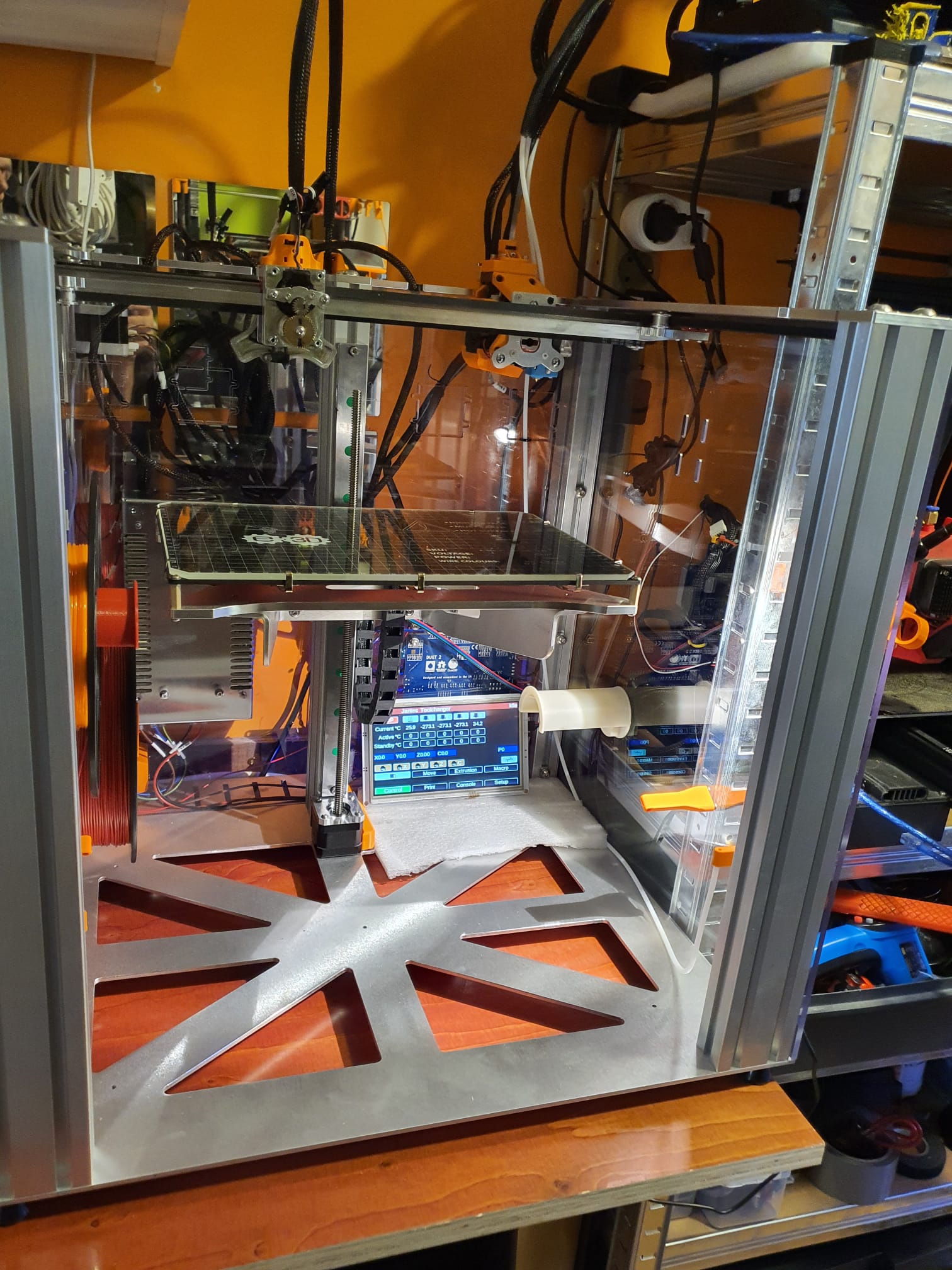

June 2022: Last week I ordered the E3D toolchanger 3d printer kit and today I built it (almost completely).

The delivery went a bit awkward from England, because of the VAT and clearance fees you have to pay in NL.

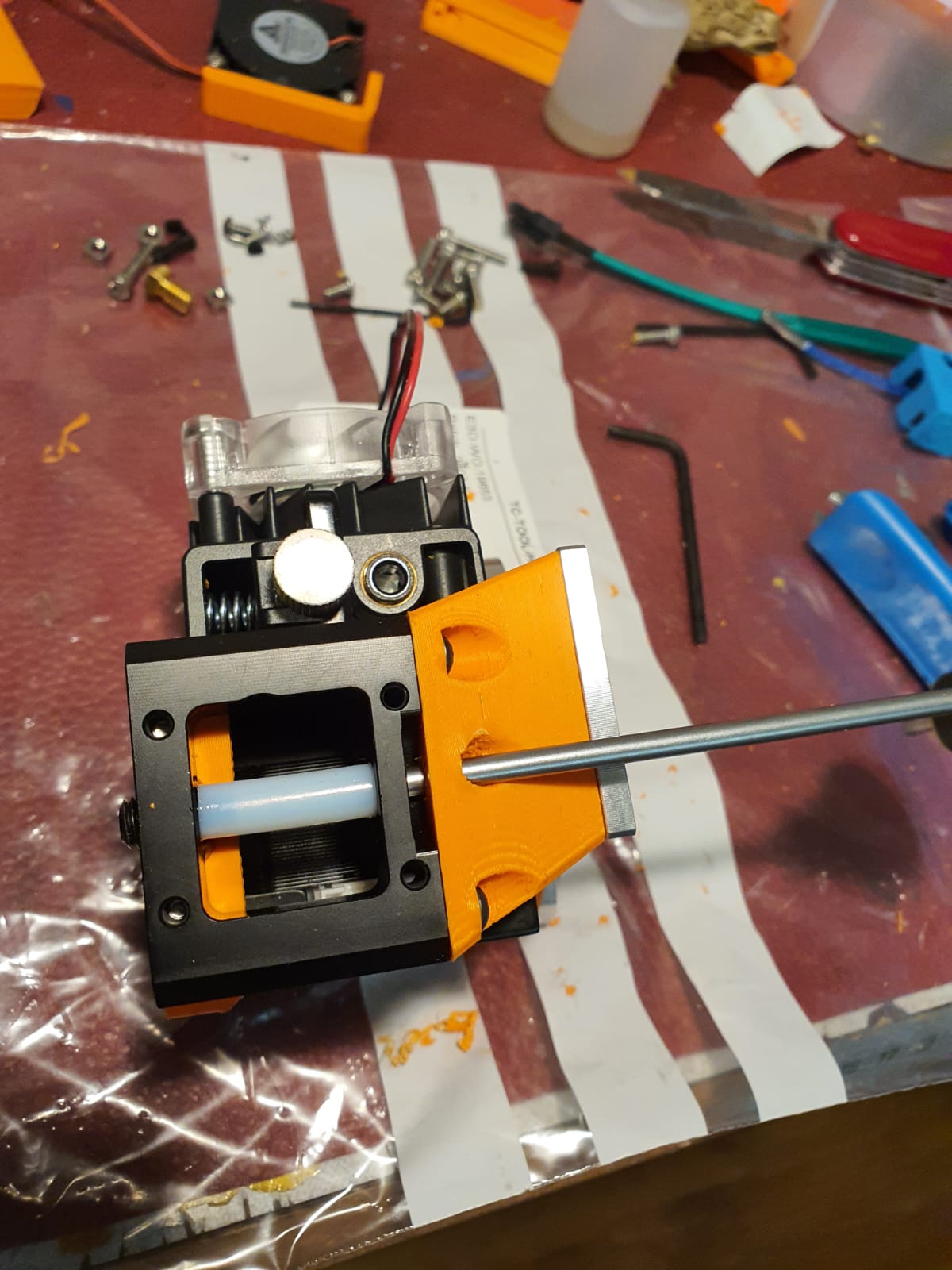

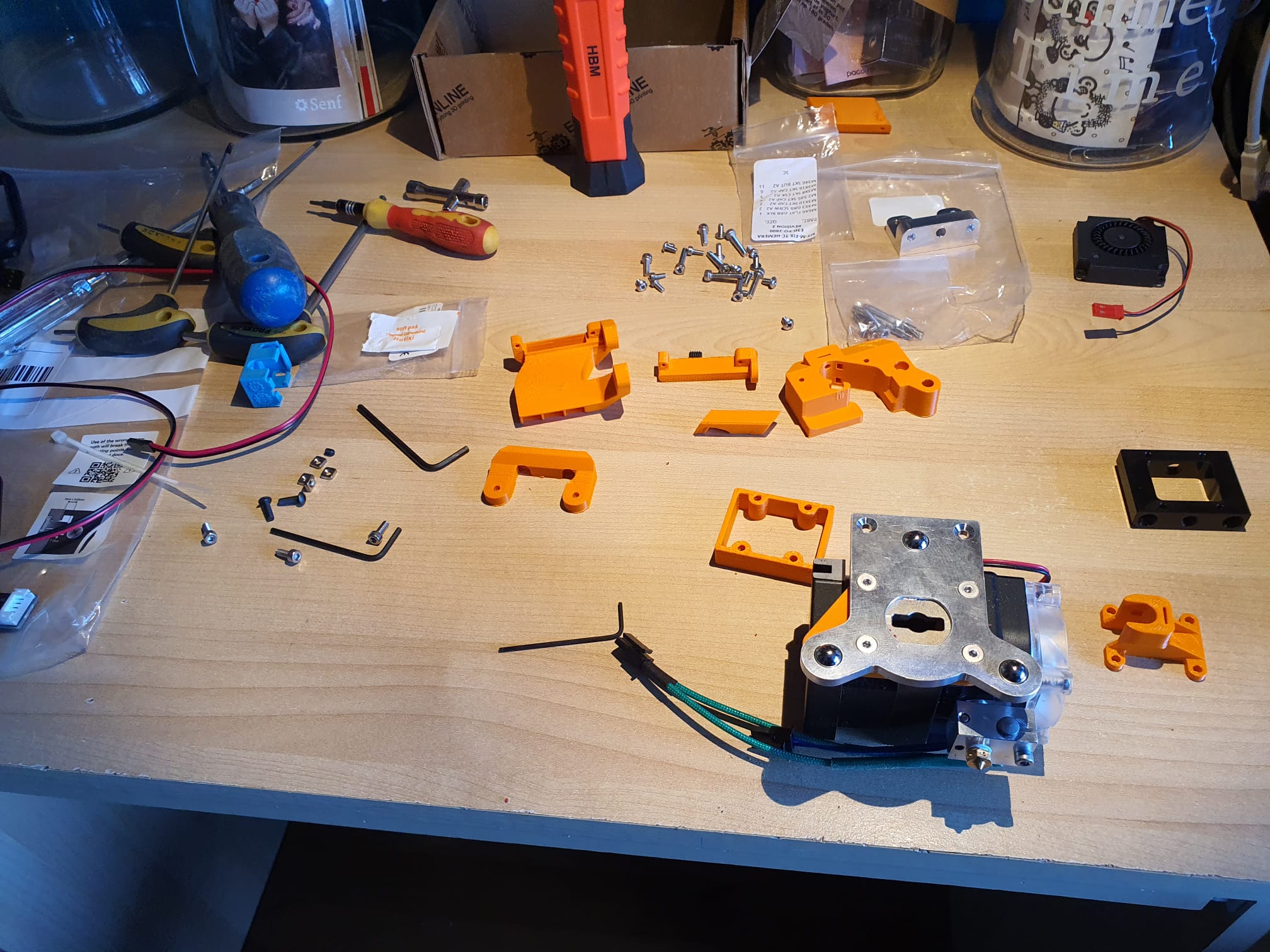

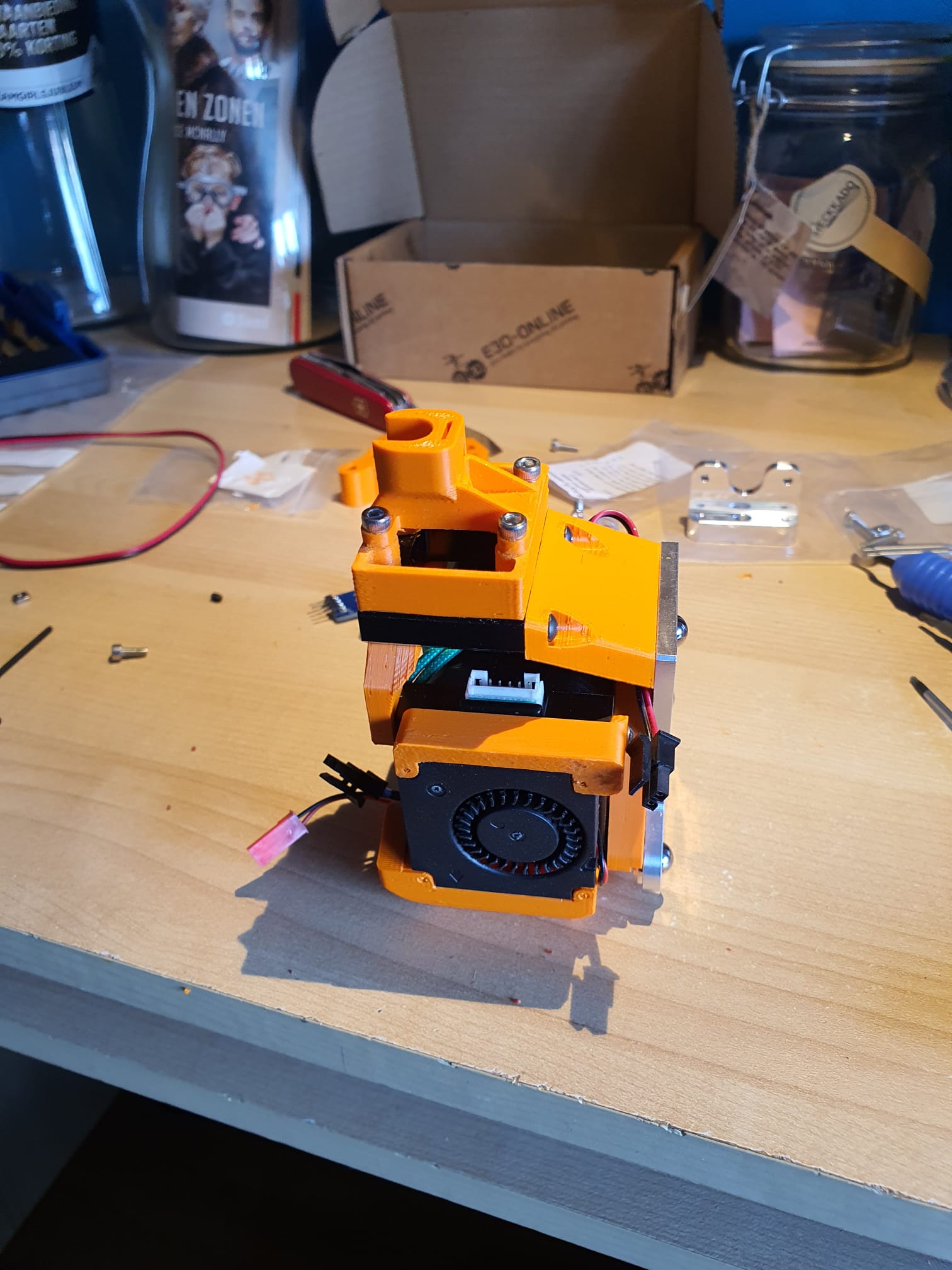

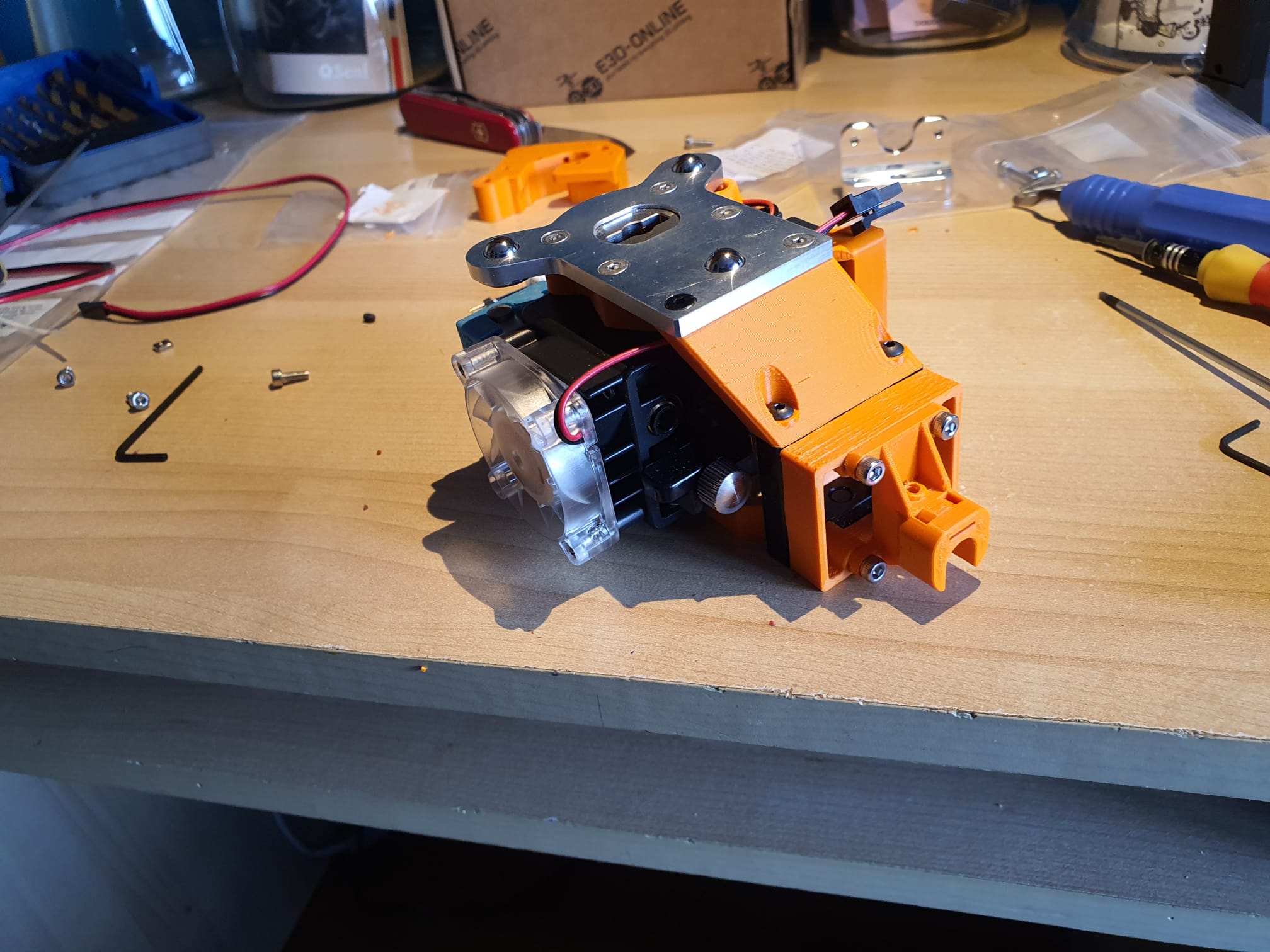

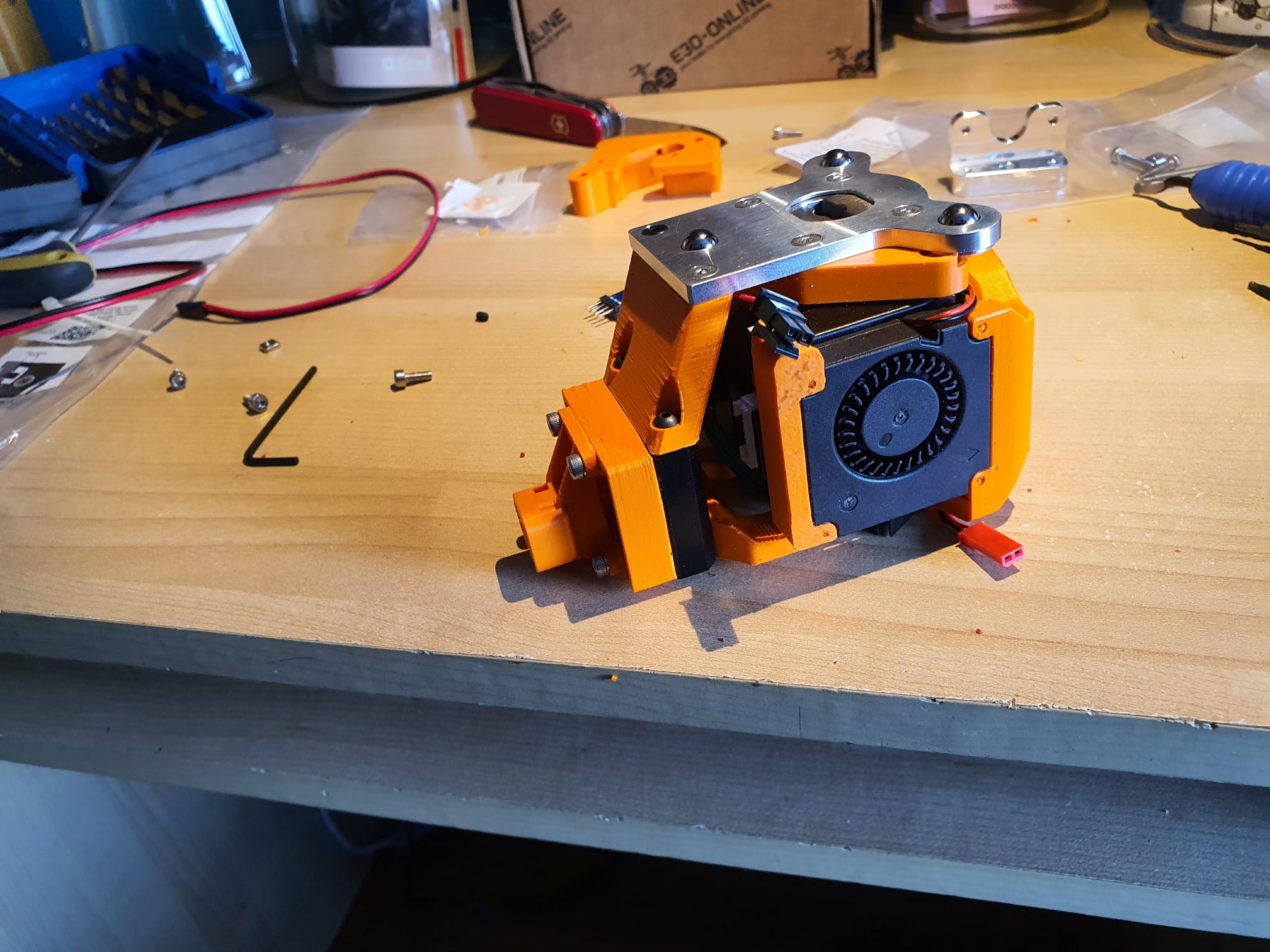

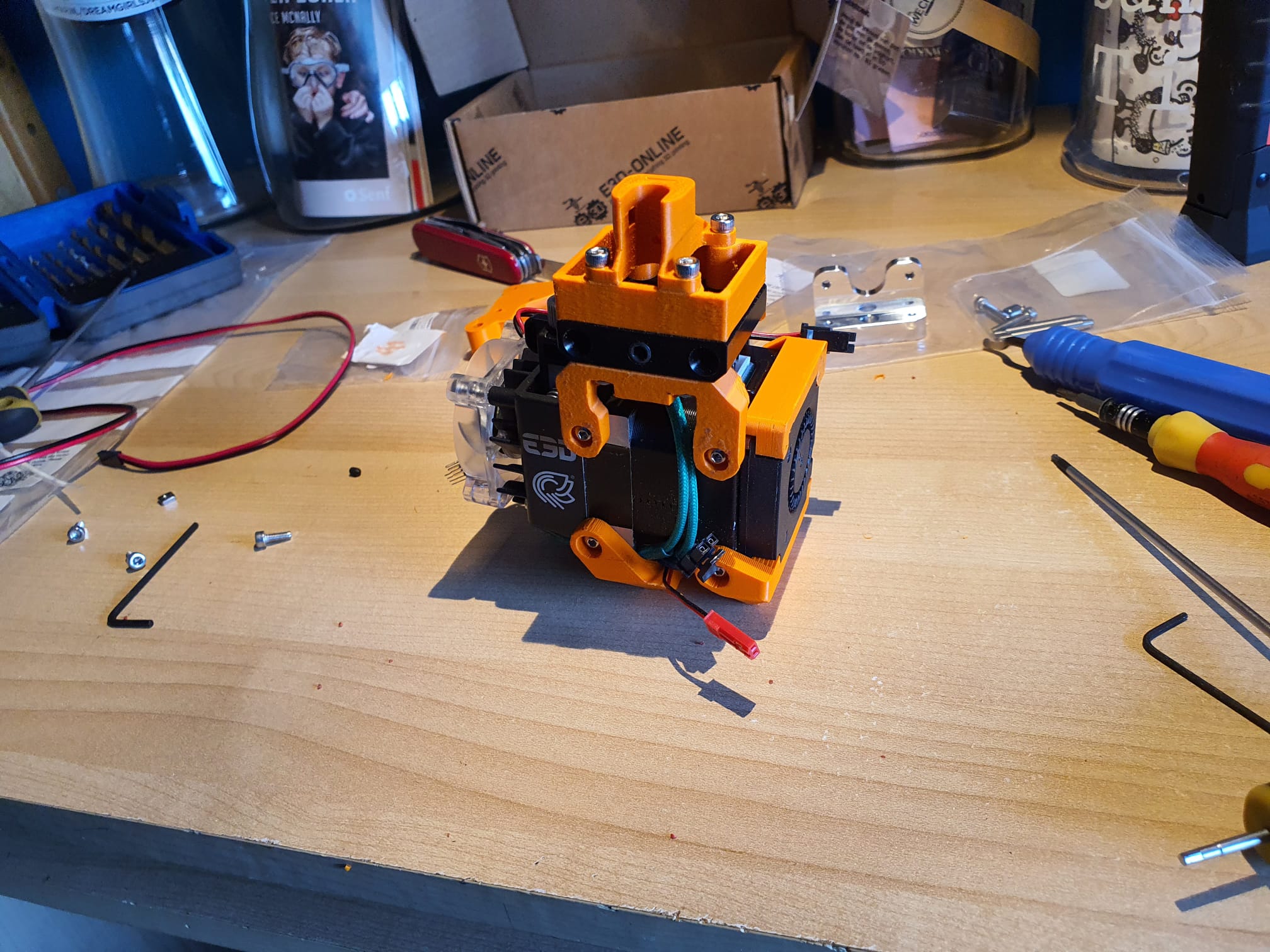

Because my Voron 2.4 is fast, but could not print everything in one day, I have to assemble 3 more extruders.

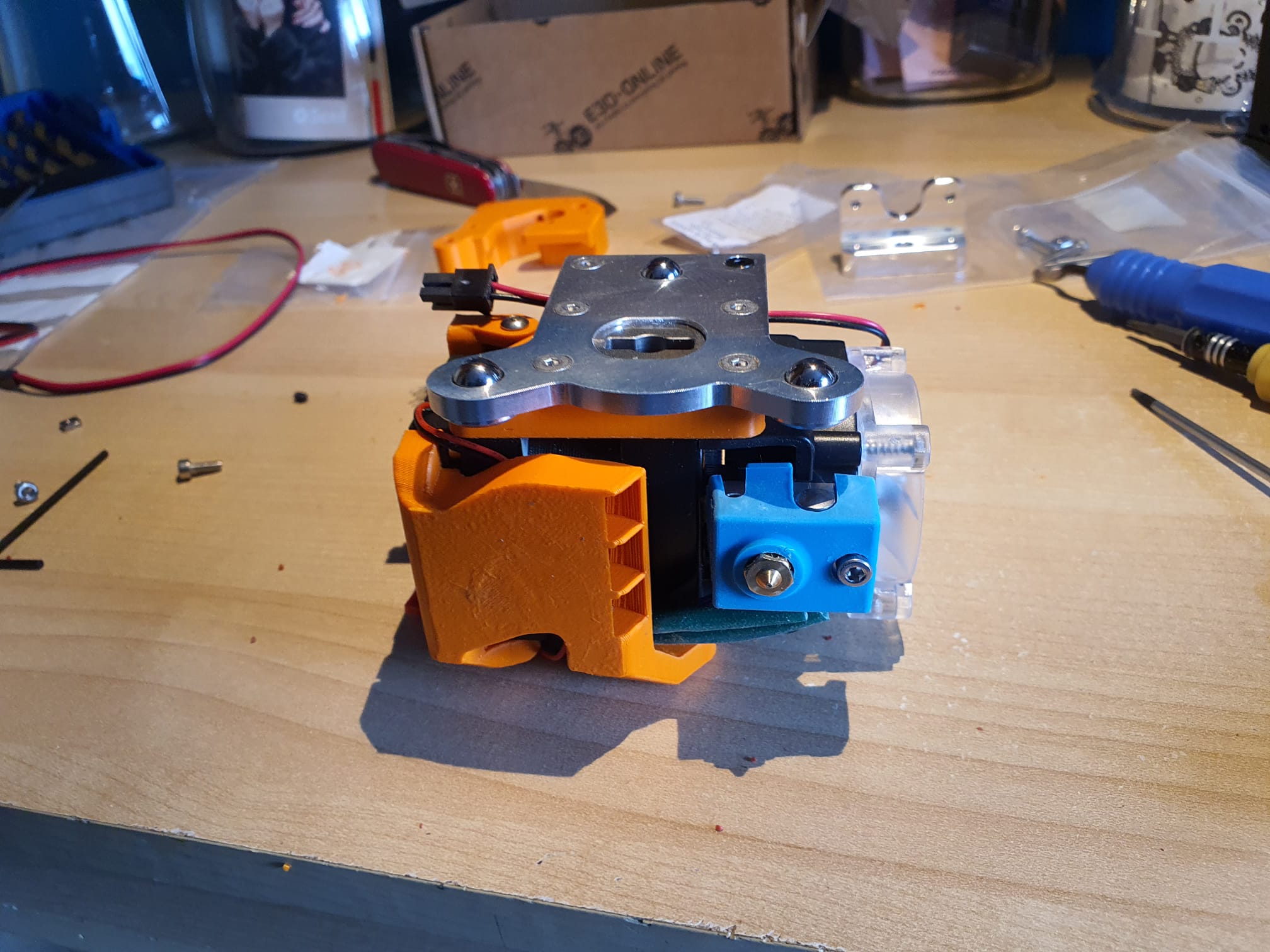

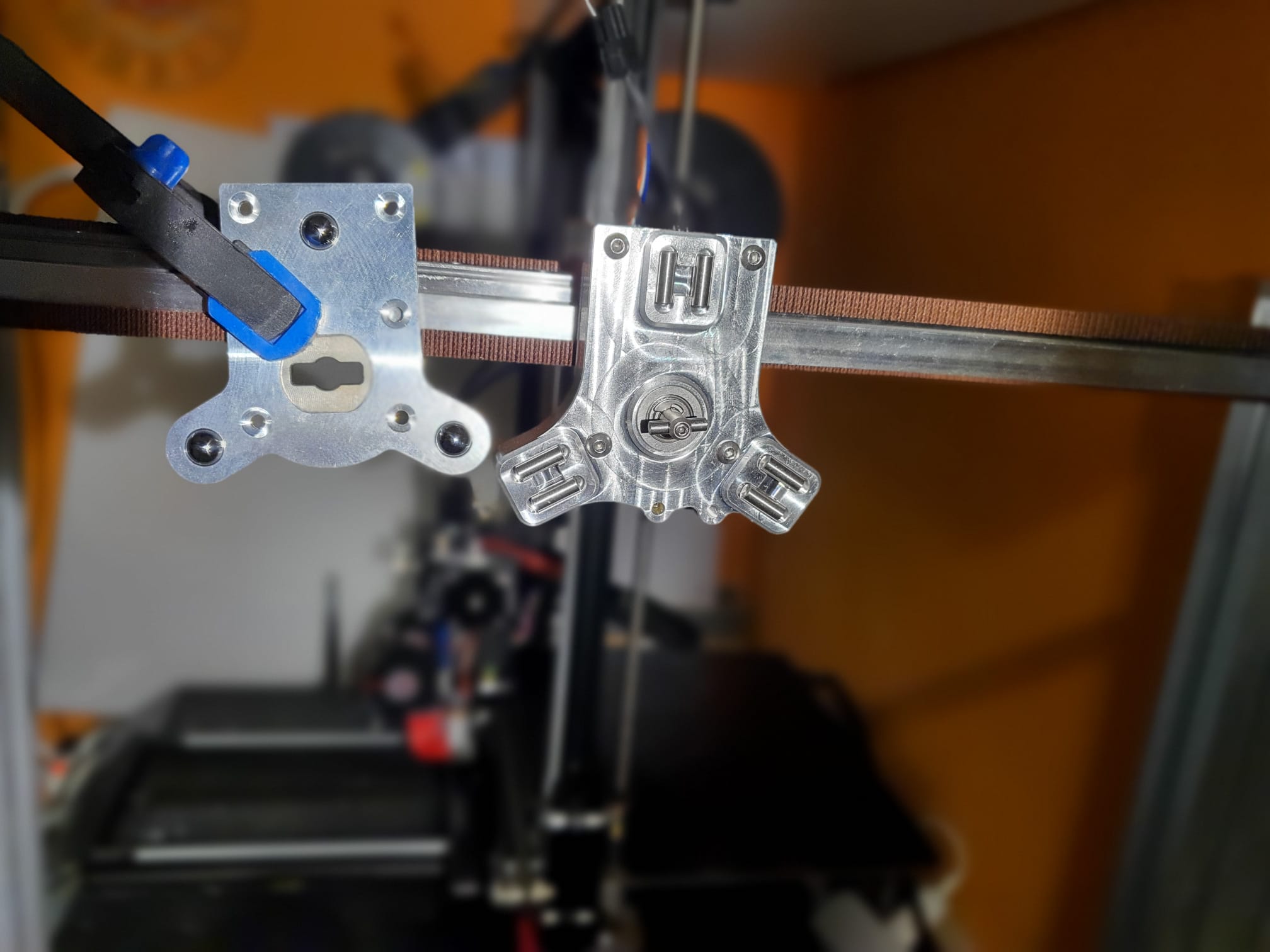

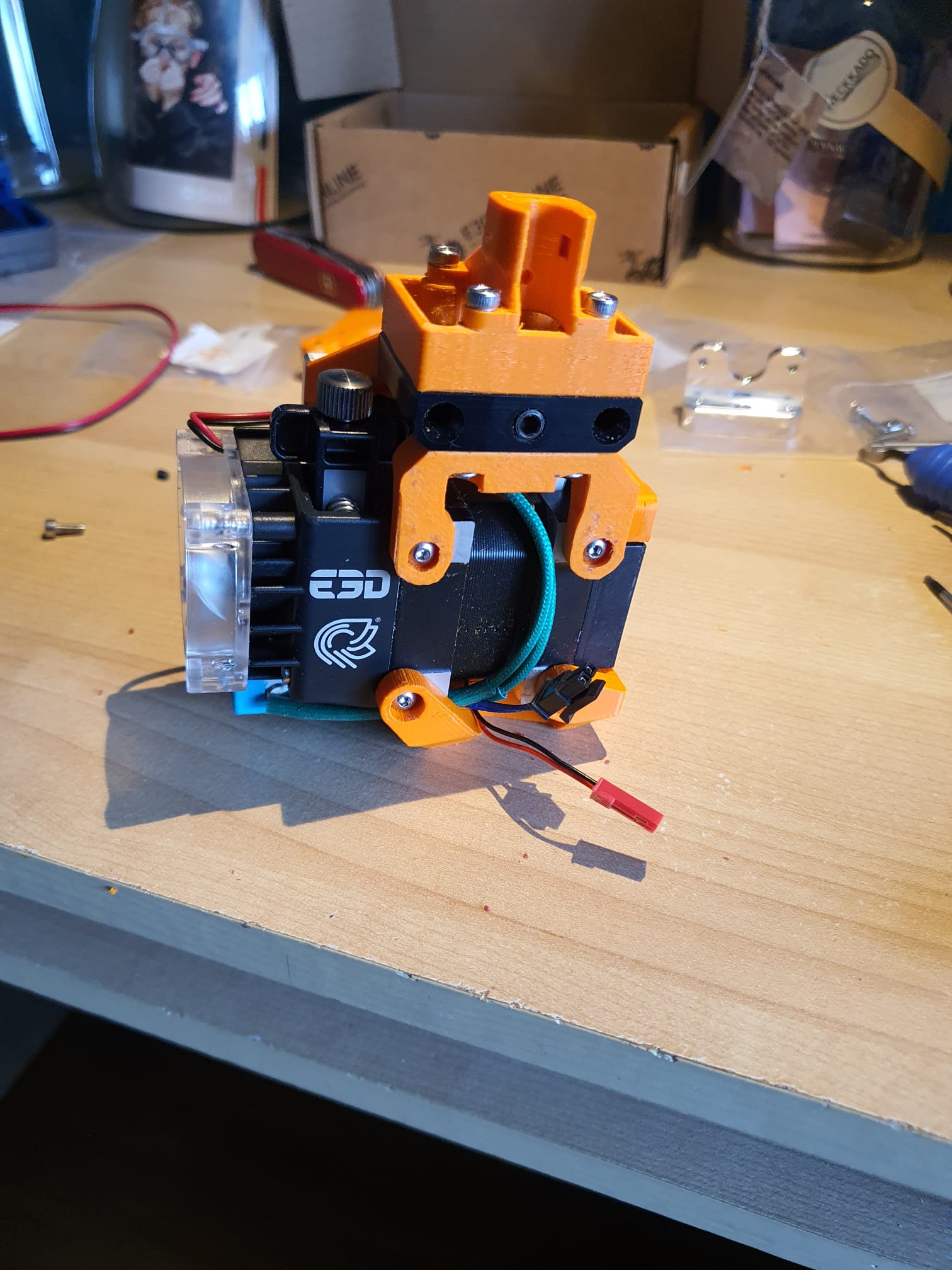

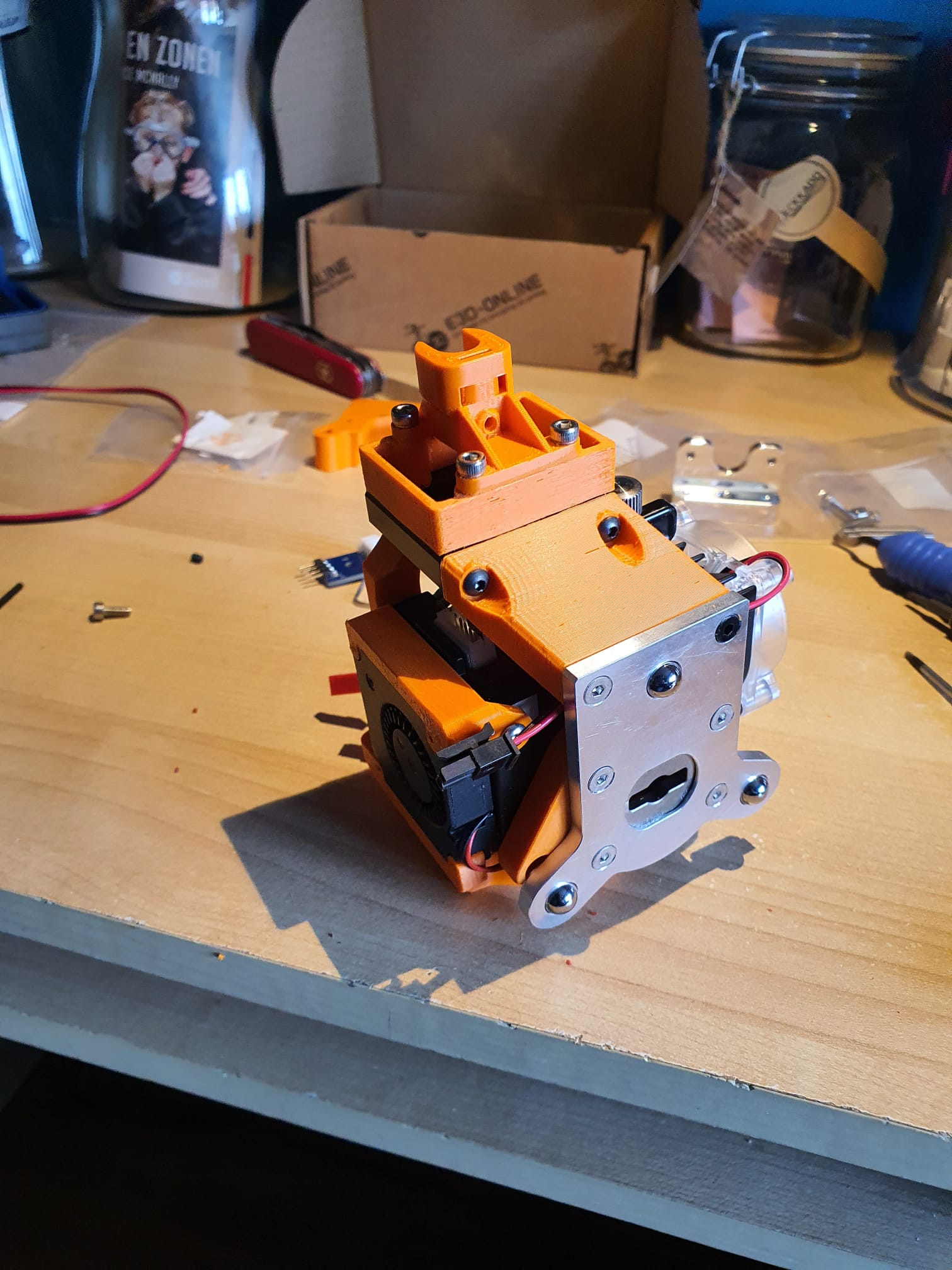

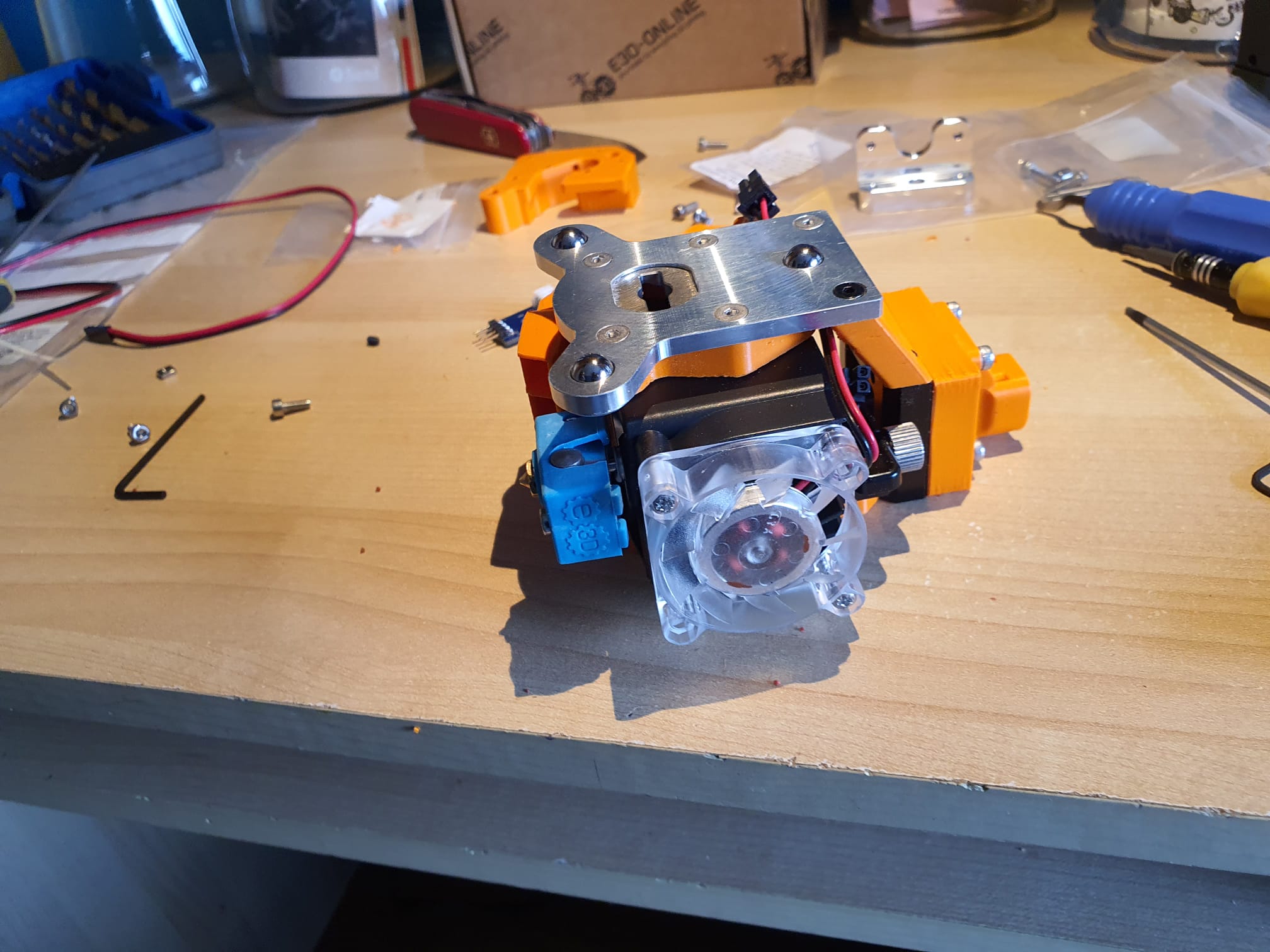

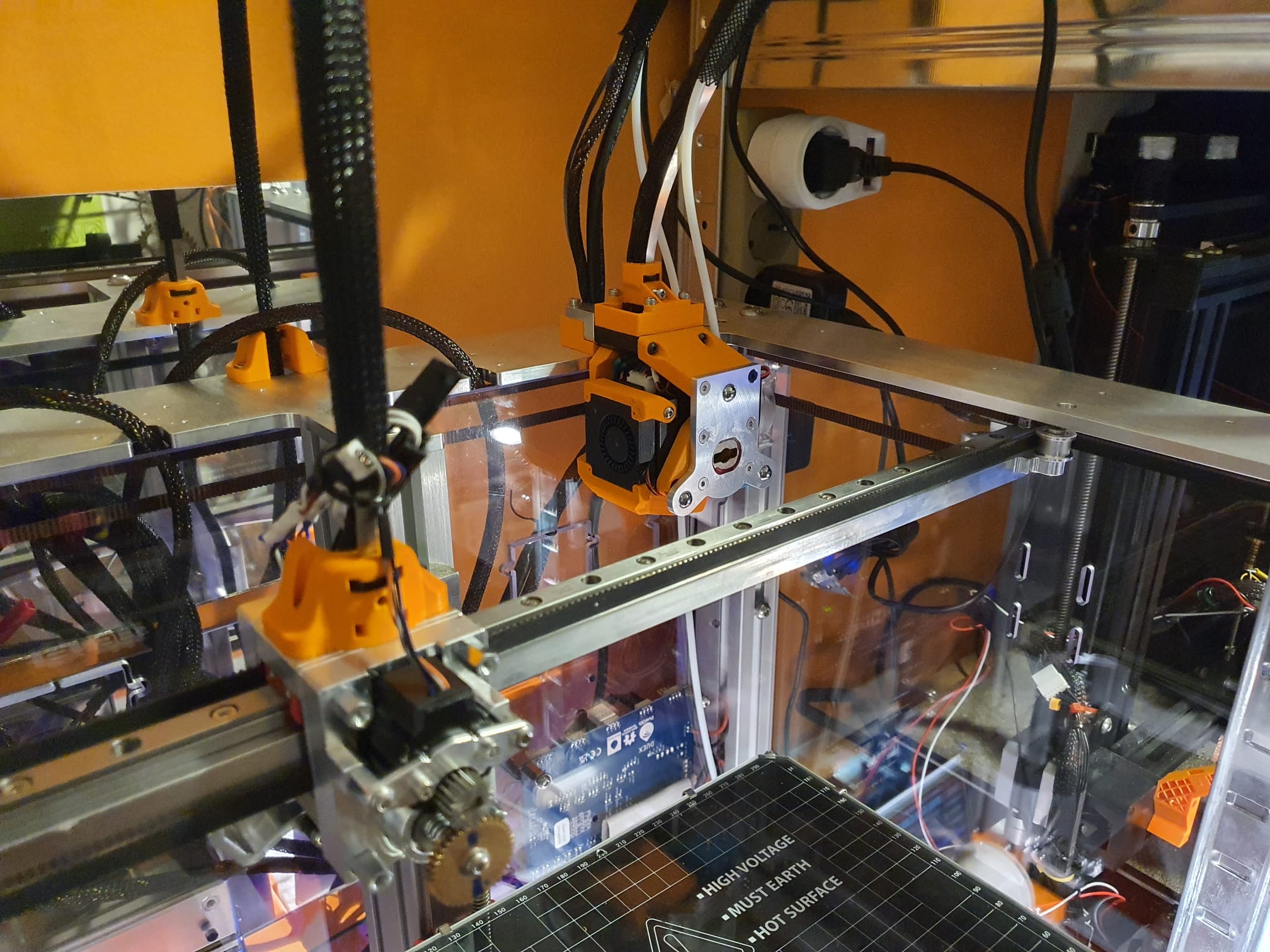

Below you can see my shot with a Hemera direct drive extruder mounted on the right side.

To be able to follow everything on the video, I set all of the tool change speeds to 10x slower for a moment.

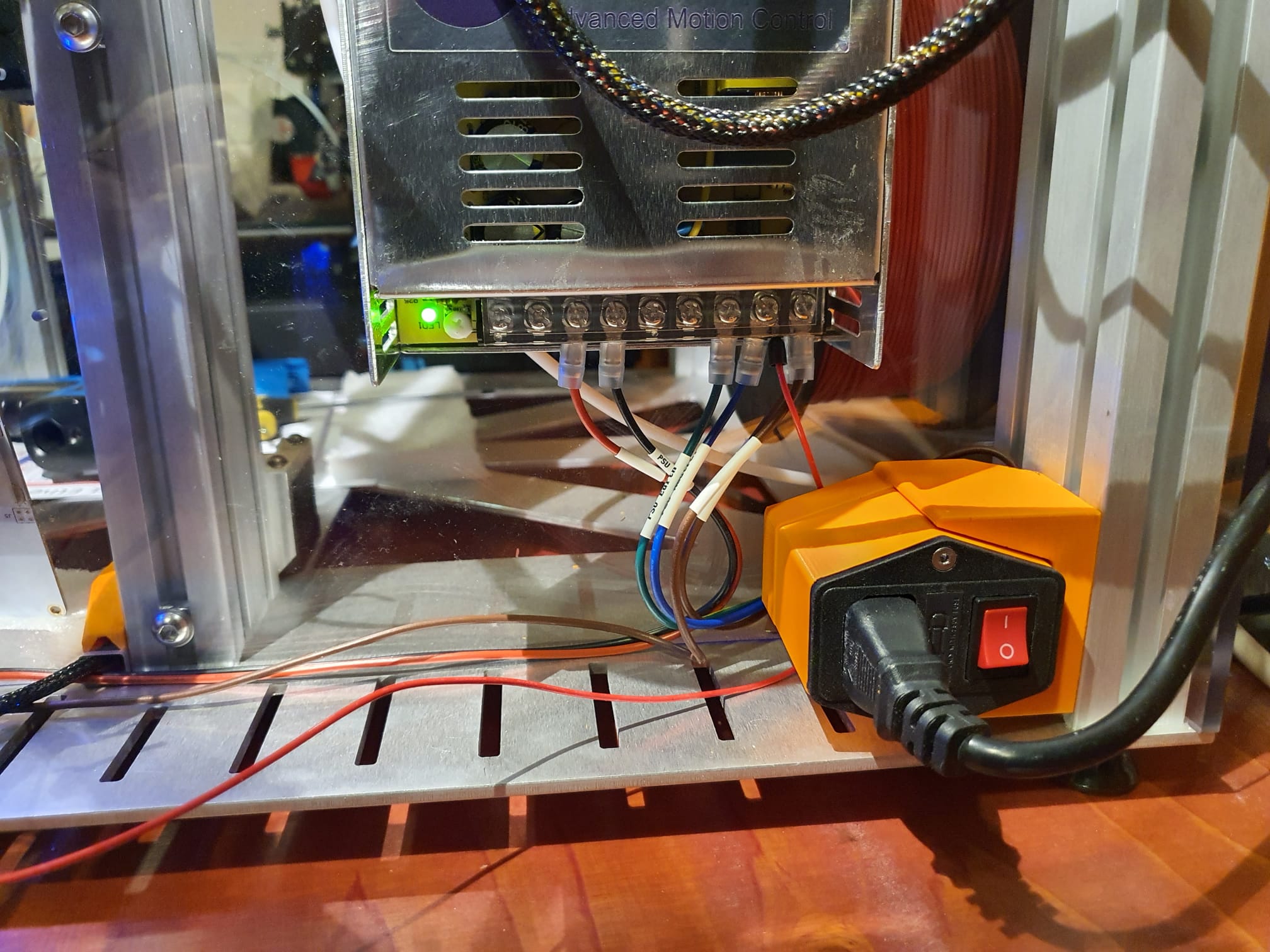

After the first day of test runs I swapped the original Duet2wifi board for a Chinese clone.

From the clone the wifi is impeccable, but the new updated wifi module on the original Duet2wifi is also with all the updates not working properly.

Every time I perform a remote reboot after a config change the wifi crashes and the board eventually connects fictitiously to IP address 255.255.255.255.

Searched all sites for help but found nothing.

Lack of experience can hardly be it, I have plenty of printers running fine on duet2wifi.

Just to be sure I have ordered an original Duet ethernet board, then I can convert the original board to duet2ethernet and I can at least still use it.

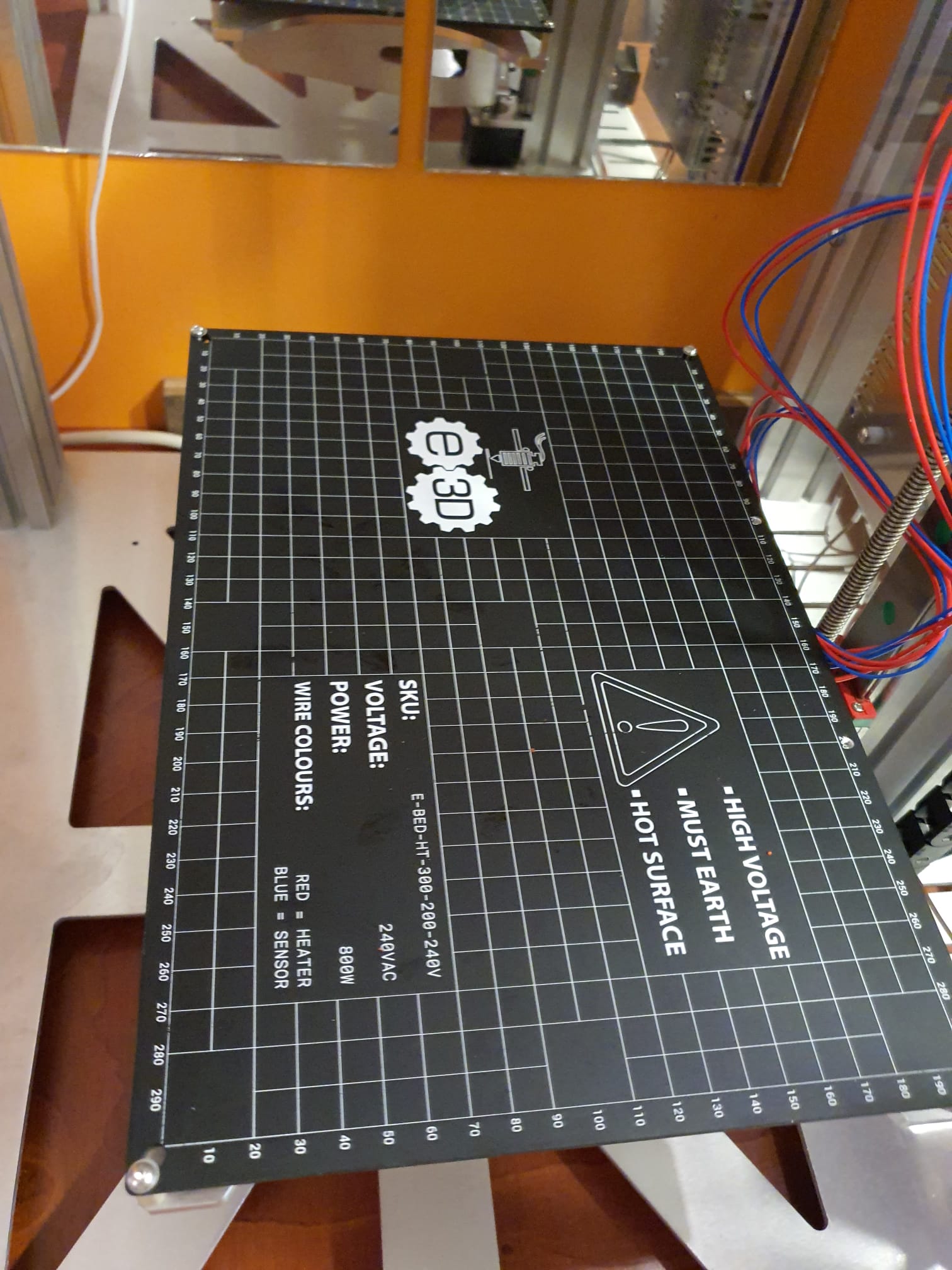

I ordered the version with 4 tools, the direct drive hemeras. I also want to work with soft filament.

The nice thing about this experimental printer is that everything works with Duet, and I have quite a bit of experience with that.

The E3D TC will be my first semi-pro multicolor printer.

I have an Ender3 pro with MMU2S, an A30M with Chimera dual nozzle and an I3BearV3 with dual magnetic carriages.

But out of these 3 systems there is no one that really makes perfect prints. They each have their specific qualities and features.

The Ender3/MMU2S can quickly print PLA and PETG with 5 colors but requires a filament spillage tower on the bed and is very cumbersome and slow to use.

TheA30M with Chimera is nice and fast and large (300x300x400mm) in build volume. But the print quality is reasonable at best. The dual nozzle Chimera with the nozzles at the same height hits with each movement just with the unused nozzle the tip of the filament deposited by the active extruder. This results in smudges and a less beautiful print. Yet I use this reasonably often, especially for quick test prints and at 0.2 0f even 0.3 mm layer height. That works fine.

First impressions:

I printed everything with orange ASA on the Voron 2.4 at 150mm/s and 0.2mm with the E3DV6 direct drive Voron extruder and a 0.4mm copper nozzle. Again, that went great!

By the way, there is something to note about this kit.

It is definitely not an ‘out of the box’ working system.

The hardware is outstanding, so are the manuals, better than anything I’ve ever seen.

The Duet and Duex combination is perfect and all the cables and screws, nuts, pins, gears and so on are nicely labeled and of fine quality.

The available config files, macro files and example print files are also great to start with.

And therein lies the problem for non-experts: All values are set to the best possible configuration.

And depending on your choices of extruder, bowden or no bowden and so on you have to make some adjustments here and there.

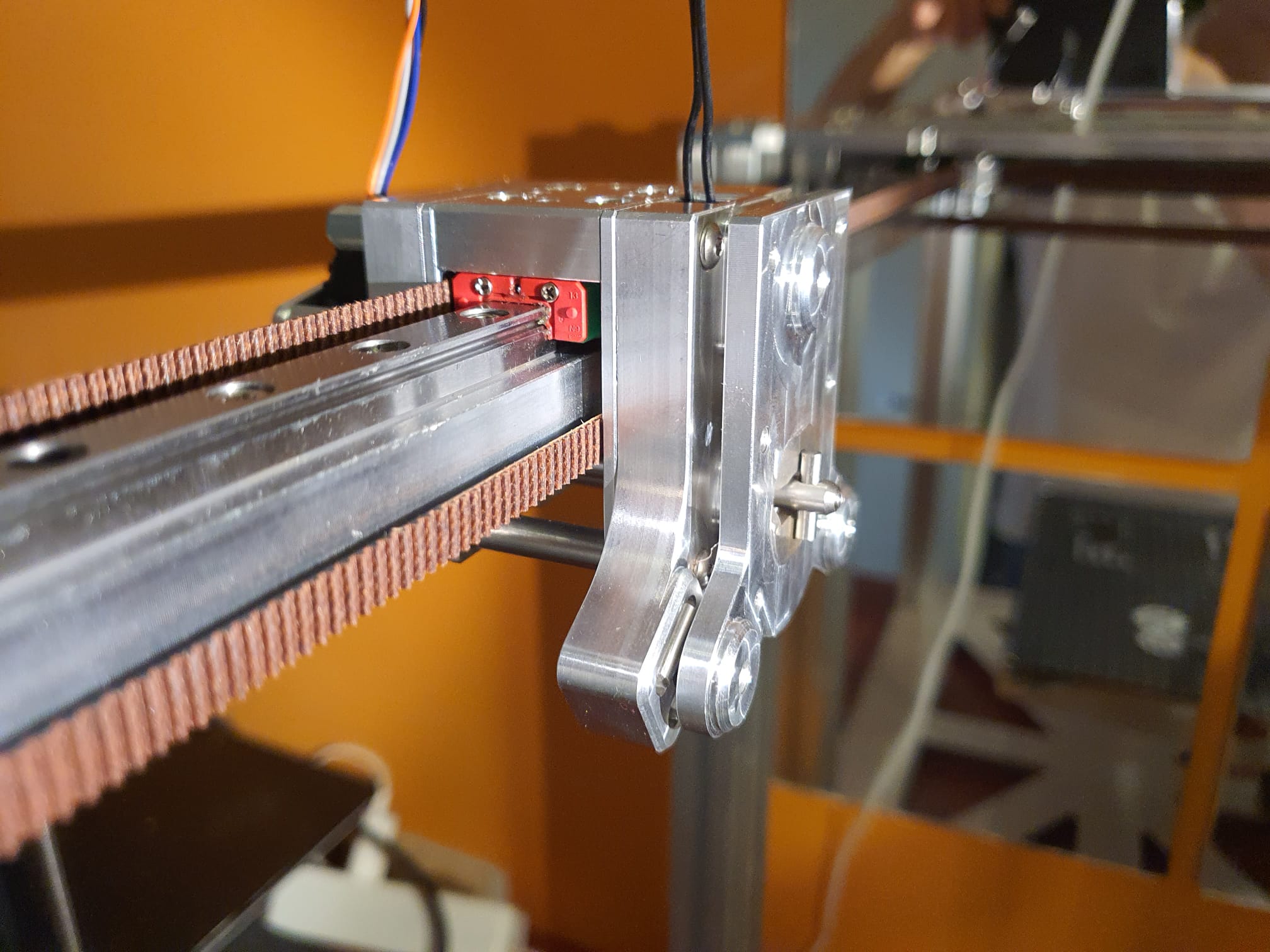

I had to recalibrate everything in terms of pickup Y values in the tool changer files before the tool was actually picked up and returned nicely.

In addition, it turned out that the tool pickup has to be adjusted very accurately to get the slot in and out of the extruder plates.

You have to understand how this is built, especially in the firmware.

Then you understand that the system has to reset to the start position every time at the start, and then the system makes that the reference point. Then you have to measure where 1) the open position is and 2) the locked position is. Those values must be entered as C values in the pickup and return macros.

What I also find difficult is that there are no sensors (yet) to check whether the tools are in use or parked.

That means that you can just give a command to do a homeall while there is still a tool hanging on the pickup.

I would like to know that because then you program around that.

And so there are some other things like no filament sensor on the tools, no LED lights on the pickup but I’ve already seen a handy bracket for that.

So a very nice and good system, worth its money and high quality material, design also beautiful and still much to tinker with. Thank goodness!

In any case I’m going to reuse my Z-homing files from the previously built mullti- extruder machines with Duet.

Because this E3D works with a pre-homing without the tools hanging from the pickup, you will have to calibrate a Tool at Z distance relative to the pickup value every now and then.

And also the mutual differences in X and Y of course, relative to Tool0.

I have some nice macro tinkering for that too!

Next week onwards!