STANDARD ABS start settings

Nozzle: 265 °C, Bed: 110 °C

Object fan: 25% max from 5th layer, below this: 0%

MY USAGE OF ABS

I use almost only ABS for my professional prints with an 0.6 or 0.8 nozzle.

That is because it is cheap, makes very sturdy prints and it can withstand pretty high temperatures.

I use ABS mainly for car’s interior parts, garden goodies and so on.

For any stuff that gets in cantact with food, kids and so on I use PETG.

For any other prints and all multicolor prints I use PLA.

Since I use dedicated printers per type of filament, I hardly ever have clogs or ruïned prints.

ABS- my story

Actually, there is not one standard for ABS settings. That’;s due to the fact that not all ABS on the market is really the same type.

However, I can give you some hints for different types of ABS 1.75 mm filament, after my extensive experience with those specific types of filament.

DO PRINT MY TESTPIECE PRIOR TO PRINTING ANY OBJECT and inspect the brim, and the sturdiness of the wall adhering, and the layer adhering.

DOWNLOAD JANTEC.NL’s TESTPRINT_tilted_raster_20250902V1_STL

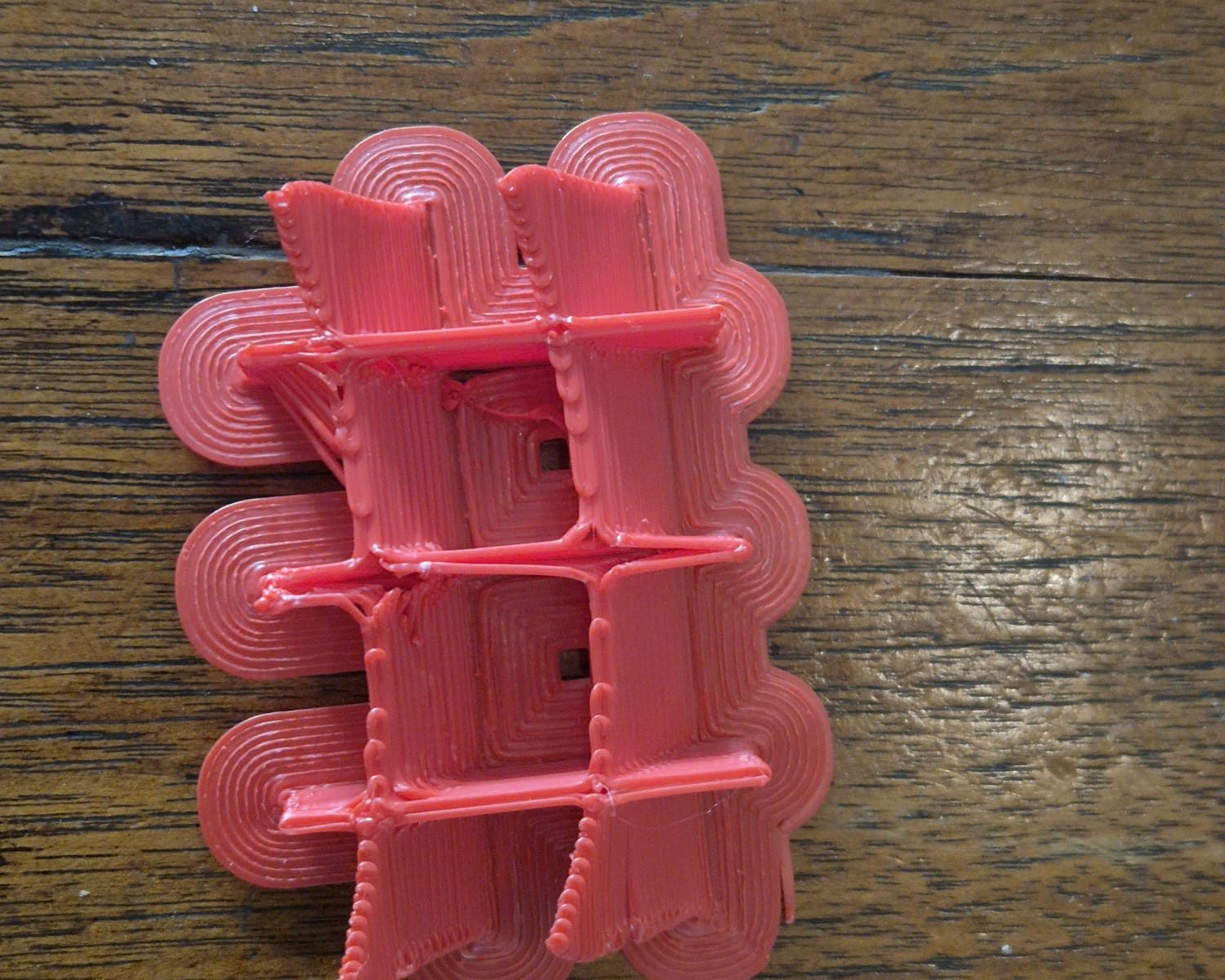

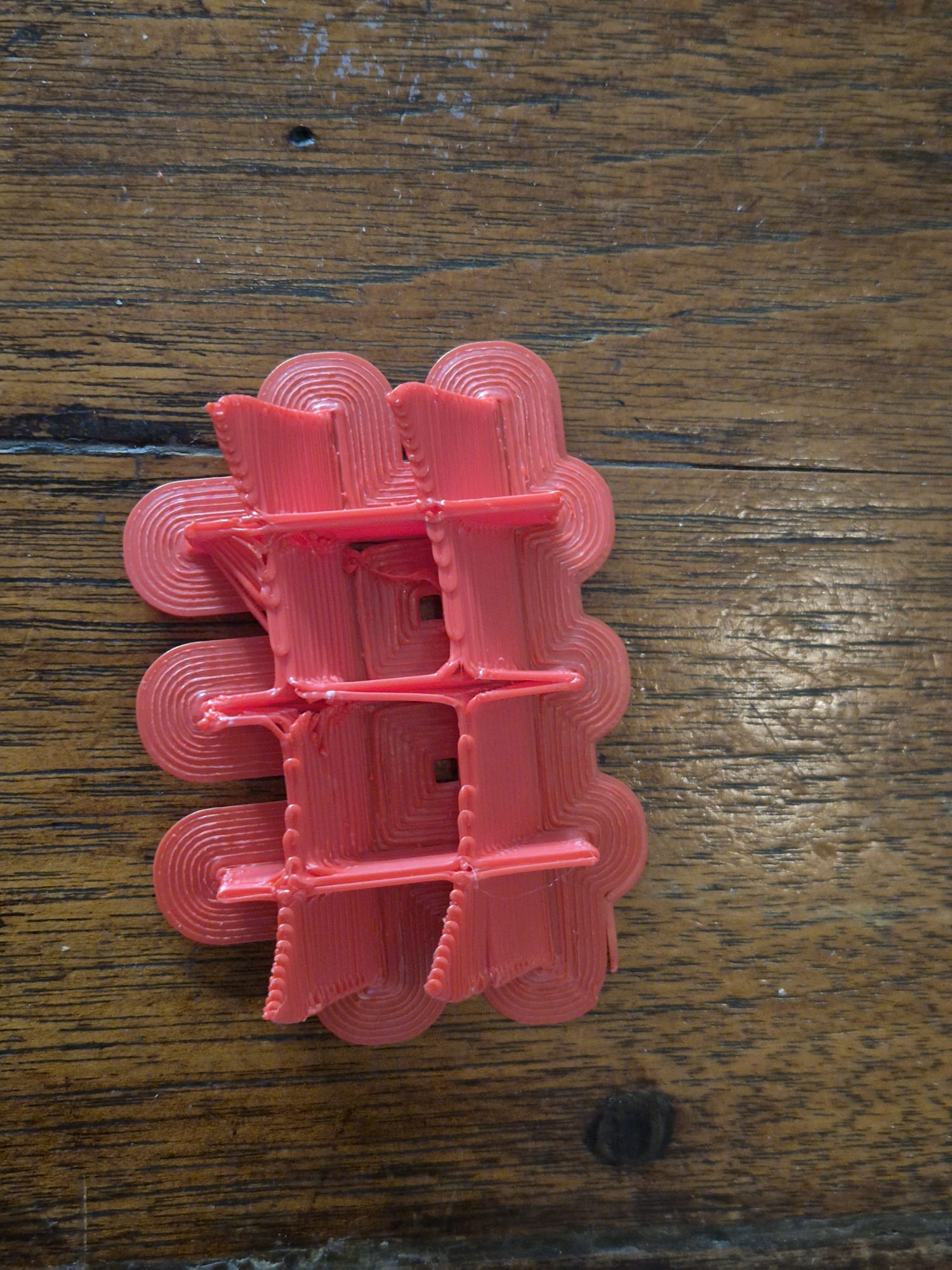

If the print comes apart if you try to break it at low force like in the above picture, the print temp is too low. Same for the wings of the testpiece as for layer adherence.

If you observe a bubbly surface, your ABS is wet. It will probably not be able to save it. You can try to dry it in an oven or in a food dehydrator at 80 degrees C, for at least 10 hours. My experience is that this is a waste of time and energy. Just throw it away in the plastics recycle bin.

GENERIC ABS PREREQUISITES

- For all ABS, you need a hotbed at at least 90 degrees C but 120 deg C is better;

- You will also need a hotbed plate with either a layer of smooth PEI on it, OR a hotbed plate with textured PEI, which I use especially for my 0.8 mm nozzle prints.;

- In general, never ever use a toolfan. Unless you are using low-temperature ABS like EASY ABS with the rquired lower bed- and nozzle temperature settings;

- Always use a completely covering enclosure for your printer;

- Always do a bed mesh that really works prior to printing ABS and make sure this is done at operating temperatures of both bed and nozzle;

- Print with a really big brim everywhere, at least 10 lines wide, also for your support structure;

- Print the first layer with at least your regular print temp, NEVER any lower;

- NO object fan on first 4 layers!

SUNLU ABS (WHITE AND BLACK)

Sunlu has ABS filament that is shiny on the spool, and can be printed shiny at the right temperature. This filament is not very prone to warping.

Nozzle: 265 deg C

Bed: 120 deg C

Object fan: 30% max=regular, no object fan on first 4 layers

EASY ABS (RED)

This ABS is also shiny, makes very sturdy prints and needs lower temp than general ABS. And- it requires a bit of object fan speed. The prints come out shiny. This type of ABS is not at all prone to warping, as far as I experienced.

Nozzle: 235 deg C

Bed: 90 deg C

Object fan: 60% max=regular, no object fan on first 4 layers

GENERIC ABS (RED, matte)

This is the most difficult to print matte red ABS(on the spool) and requires very high printtemp, and can’t handle any percentage of object fan. The prints come out matte when printed under 270 degrees and at 285 deg they are shiny. This type of ABS is very much prone to warping. This is likely a type of ABS without any additions to it.

Nozzle: 285 deg C

Bed: 120 deg C

Object fan: 0% max=regular, no object fan on first 4 layers