I bought my Traction Avant 11BN (1955 made) in june 2006, and I had to perform a lot of mechanical repairs before the car was roadworthy.

The engine block was cracked beyond repair, the gearbox 2nd gear was smashed, the brake system was really bad and so on. And the fenders were rotten in the common places. BUT- the body and the doors of the car were wonderfully intact.

AND- this car has had internal body care with either dinitrol or some other rust-preventing fluid. Everywhere the little plastic caps show where holes were drilled to gain acces to the car’s body for the rust prevention. One of the first things I have done is to do this process again, with solvent and rust preveting fluid, also on the bottom and underbody of the car.

Other parts were also renewed: Drive axles, steering joints, all lights like blinkers, head lights, dash, interior. Also the exhaust, gas tank, suspension dampeners, horns, steering wheel (temporary until the original steering wheel was repaired)

So- to get the car through the MOT inspection I initially made the mechanics work. Later on, I also made the car’s exterior look good. I chose to keep the internals of the car as they were, to preserve the vintage appearance.

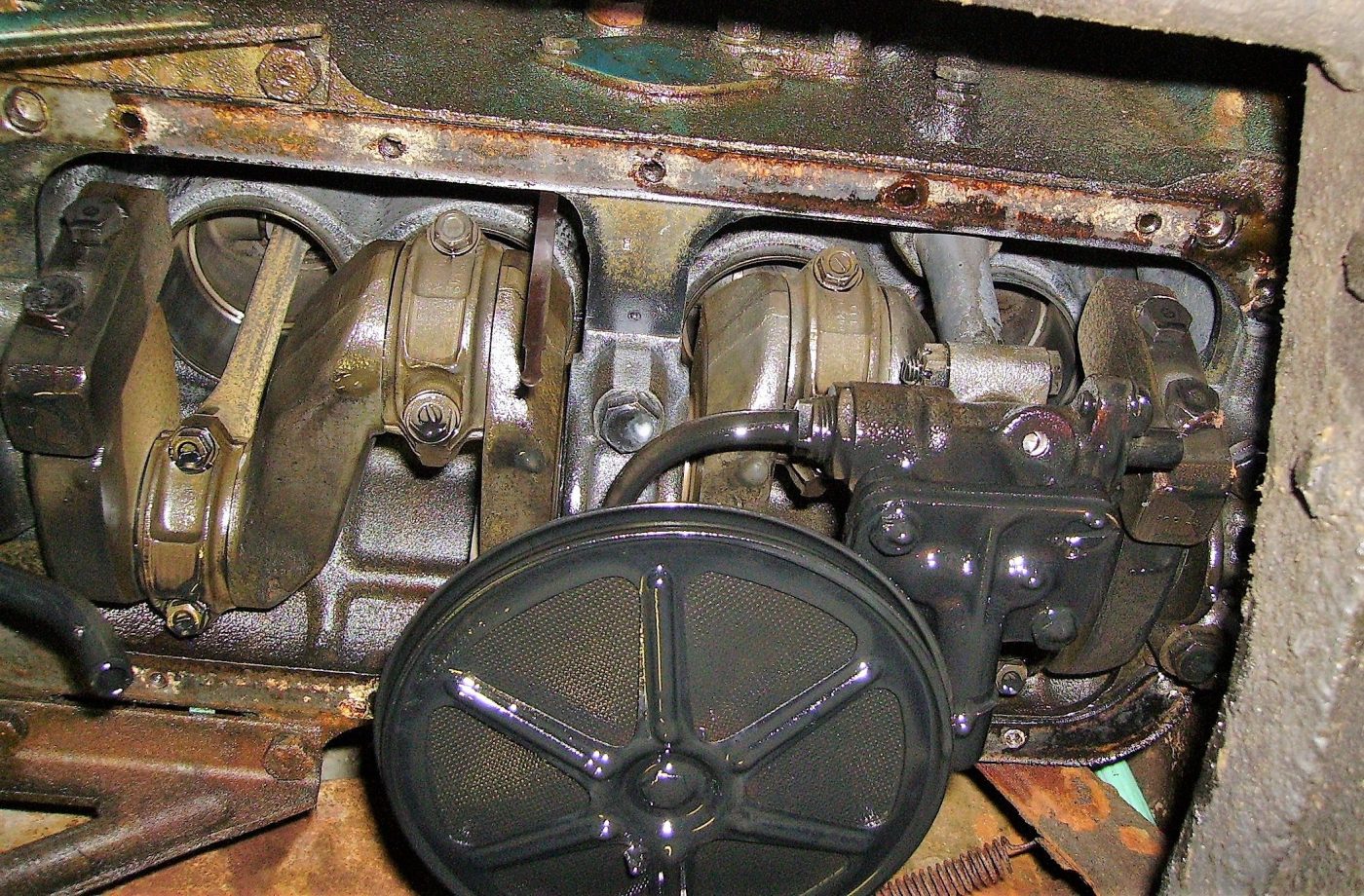

The brakes, engine and gearbox were really bad and all had to be completely overhauled.

New brake calipers, new flex brake lines, overhauled master brake cylinder, changed to DOT3 brake fluid, new brake springs, new brake shoes and – retainers, new dust covers for everything

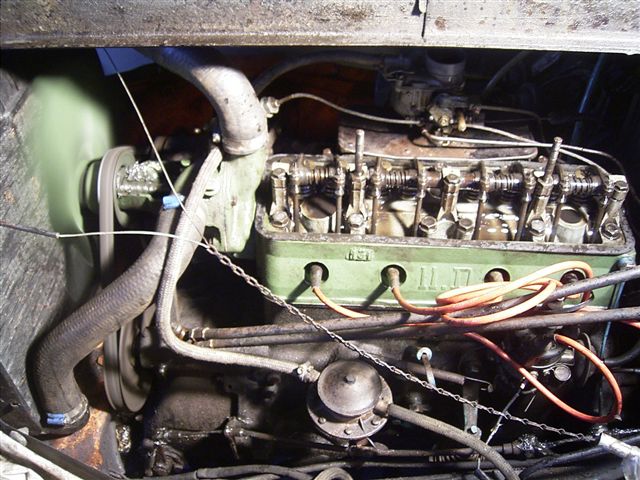

The engine was completely seized up. I had it soked in diesel for a week, took the carter pan off and freed the pistons. Bought a revised cylinder head and made the engine run again. Later, I found out that the cause of the seized up engine was a cracked underblock in the passenger’s side rear corner. But- the engine ran well again to get through the MOT.

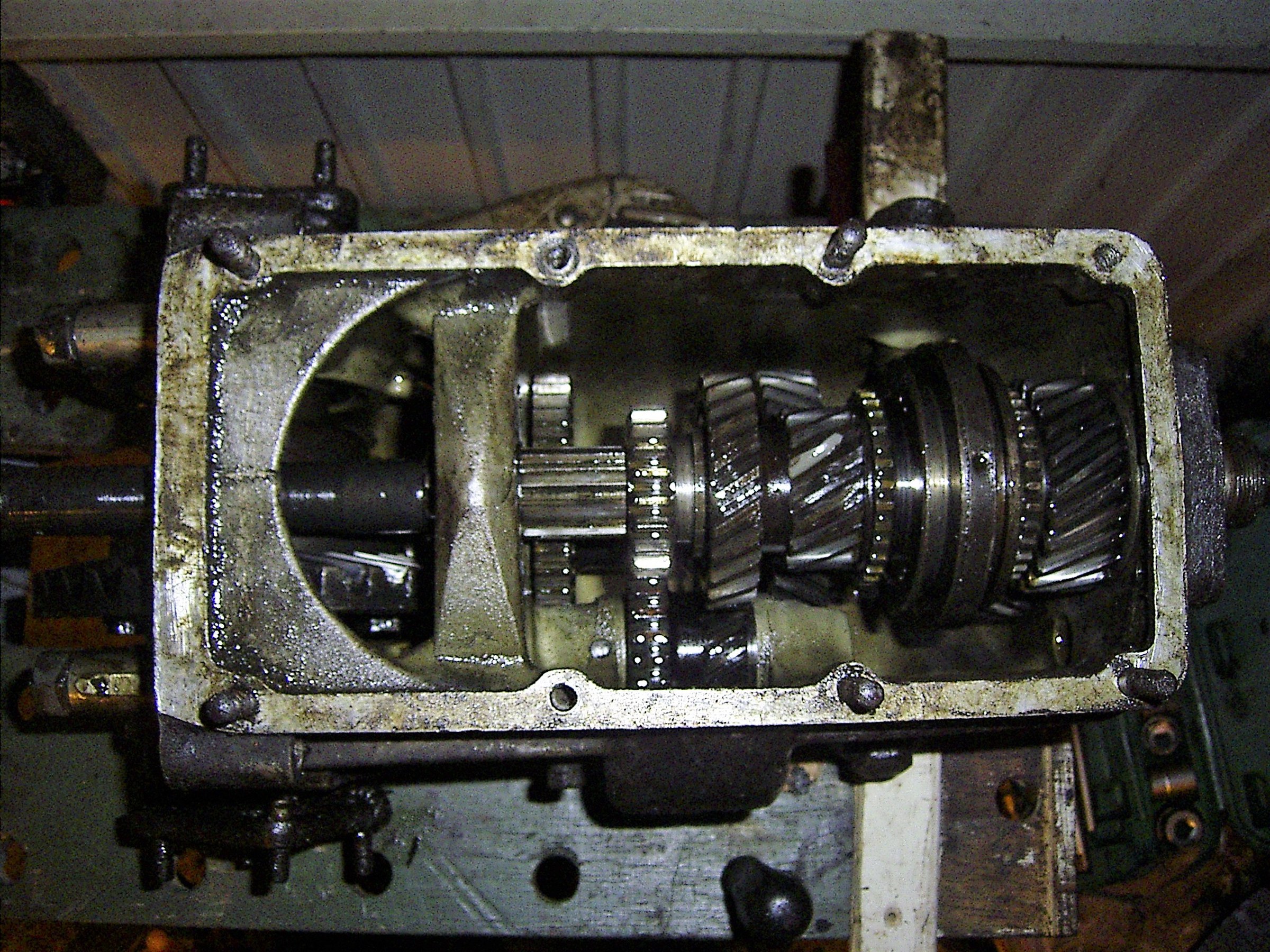

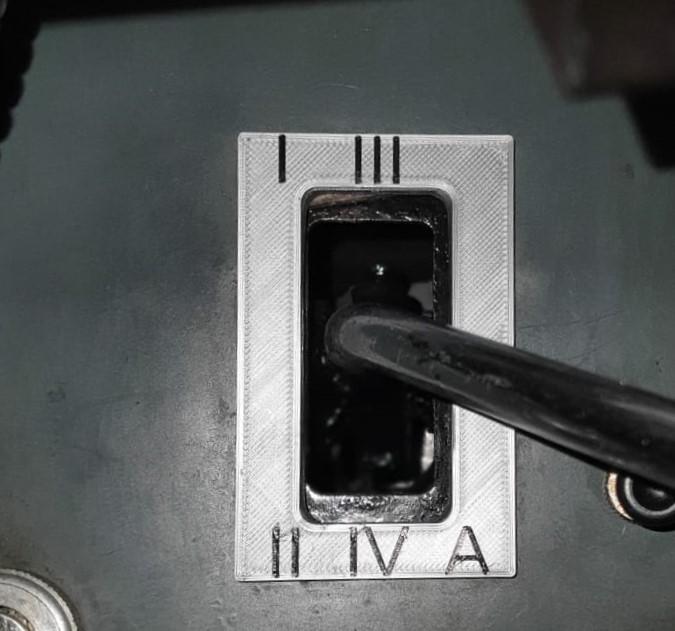

The gear box of this car is a 3-speed, no synchro on 1st gear. It is a gearbox that is not regarded to be very sturdy and thia was my problem. Obviously, the previous owner tried to get the seized engine free by towing it in 2d gear. 2 teeth were broken off the 2nd gear teethed wheel. Fortunately, the TAN club could provide me with a 2nd hand 2nd gear teethed wheel and I repaired the gearbox, replaced it and we were almost done.

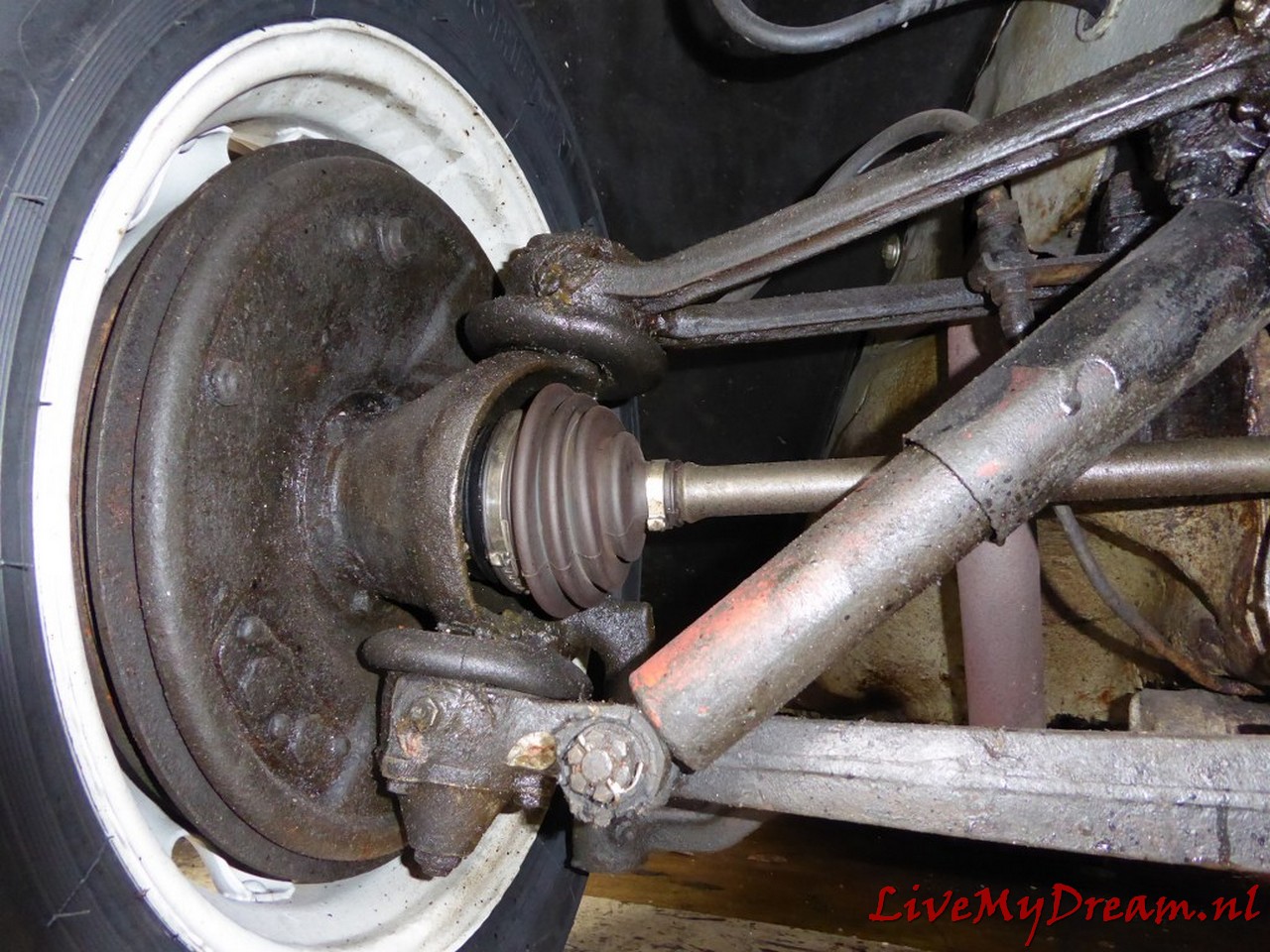

The rest of the repairs was a lot simpler like replacing the gastank, repairing all lights, repairing the original drive axles (I replaced these with unijoint versions later on) , hand brake cables, mirrors, and a lot more. Also, I had to add a red fog light at the rear.

REPAIRS

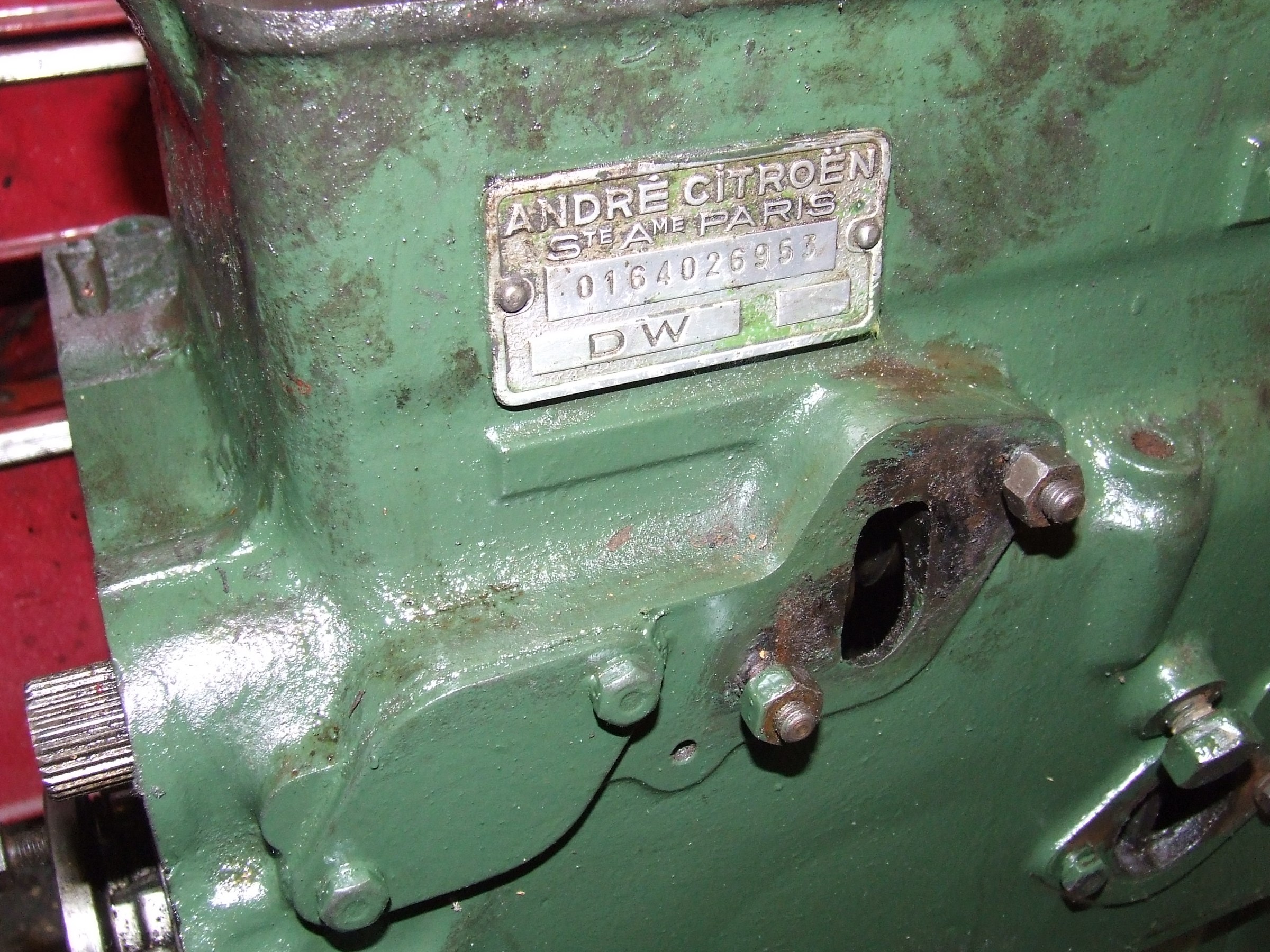

Directly after the MOT I had to do a lower motorblock exchange since the original lower motorblock could not be repaired.

For this repair, I got me a long stroke Citroën ID19P engine underblock which is very similar to an original TA lower motorblock. This all worked very well with the original TA’s upper parts and during/after the first MOT I drove with this combination for a couple of years.

OUTER APPEARANCES

Although I fixed the outside of the car to make it through the initial MOT inspection, the car was far from beautiful. I just patched any holes and put some paint over it in a similar grey color paint.

It took me over half a year to get the car in a nice external state, by repairing all bad parts, doing metal- and bodywork and spraypainting only the bad parts. In this way, I preserved over 60% of the car with original paint.

I had to do a lot of bodywork on the fenders, and some on the bottom of the doors, the raingutters of the roof, the outer parts of the bonnet, the edges of the rear window mount, the edges of the hood and the air inlet just under the front window.

UPGRADES

Later, I upgraded to the following parts (sequential order):

- New type drive shafts ‘closed’ joints

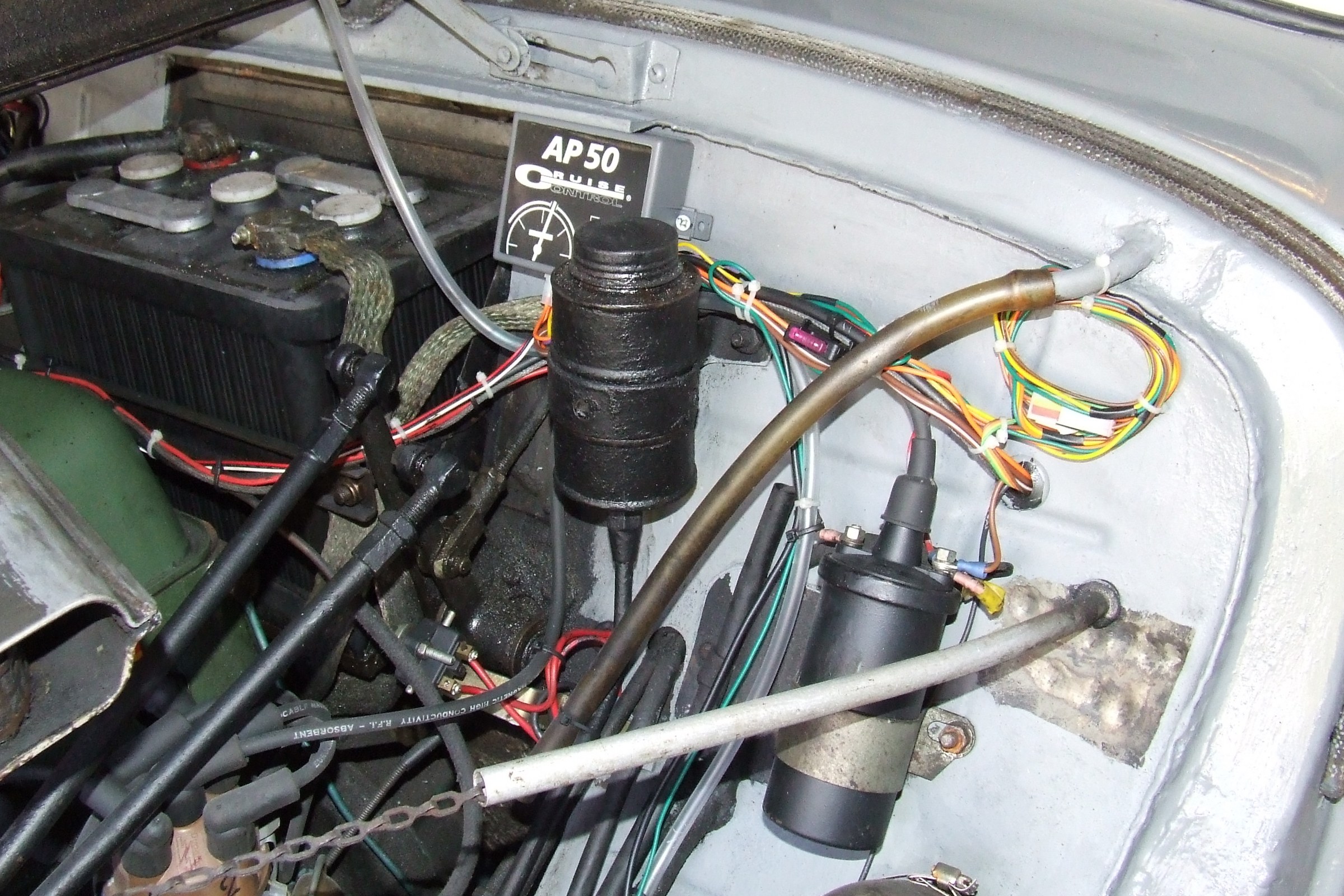

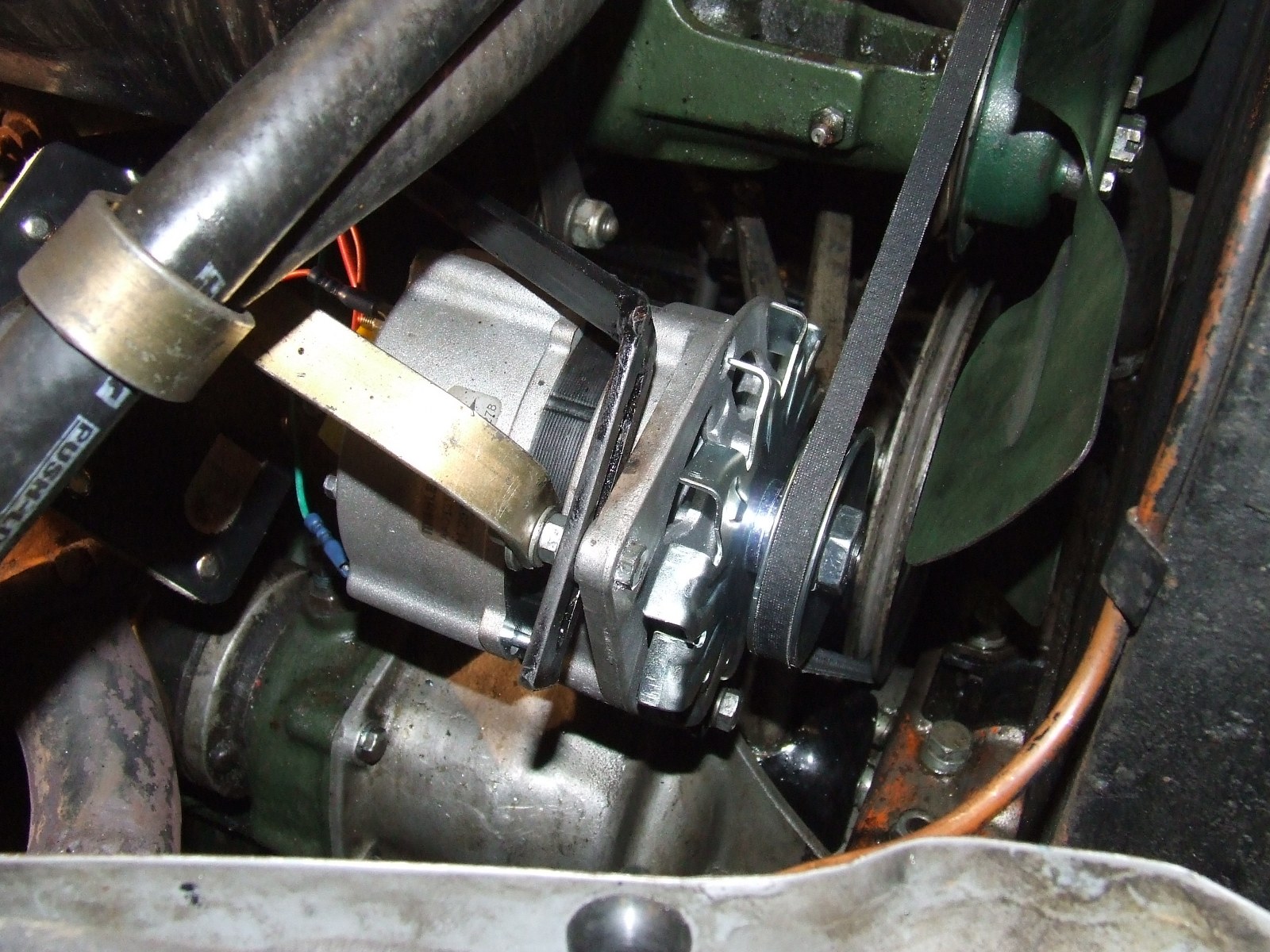

- 12V AC dynamo, regulator and all 12V electrical components incl 12V starter

- 4- gear transmission with ‘H-type’ cabin controls

- Cabin (coolant water driven) heater with front window heater

- Electronically regulated cruise control with vacuum servo

- Engine upgrade with a powerful long stroke Citroën DW engine ***

- RPM increase of 15% on the waterpump/fan rotation speed (smaller V-wheel)

***: I mated the old 3-gear original gearbox to the old TA-motor that now has an ID19P underblock. This is now my spare motor/gearbox set in storage:

MAINTENANCE PHASE based on max 2000km/year

Every year:

- Top off the valve saver fluid.

- Before the car is parked in storage, add fuel preserver fluid in the gastank and then run the engine for a couple of minutes.

- When I pick up the car after storage, I always check the coolant level and the brake level fluid and I make sure all brakes work properly. If I need to top up the DOT3 brake fluid, check which wheel is leaking and check that wheel and brake pistons for any wear. Clean up and mount all properly back. Check tyres for wear, correct fit and pressure. Check horn. Check wipers. Check lights. Check engine oil. Check fuel levels. Top off the valve saver fluid.

PLUS Every 2 years:

- Fill all the grease joints with appropriate grease, according to the TA’s grease scheme. This goes for steering, suspension, old model drive axles, drive shafts & bearings, gear selector rods and -mounts, waterpump, and so on.

- Replace the engine oil with non-synthetic 10W40 every 2 years, since this car does not have an oil filter.

- Measure the hygroscopic value of the DOT3 brake fluid and exchange the fluid when needed.

- Check the level of the gear box oil and top it off with non-synthetic 30W80 engine oil.

- Adjust the engine’s valve clearances.

PLUS Every 4 years:

- Check the spark plug gaps;

- Check the head light’s height settings

- Check the front wheel’s toe setting, and adjust when needed.

- Check the brake clearances and adjust when needed. Also, I check the speed at which the brakes free themselves after using them and when this is slow, I take of the hub and make sure everything moves smoothly. I needed, I clean the brake pistons and caliper of all wheels (If 1 moves slowly, all need maintenance).

Afterthought: I am glad that I am by now very experienced in doing all of my maintenance myself, and having a place to work with all the required special tools available helps a lot!

For things to come: Please see THIS: