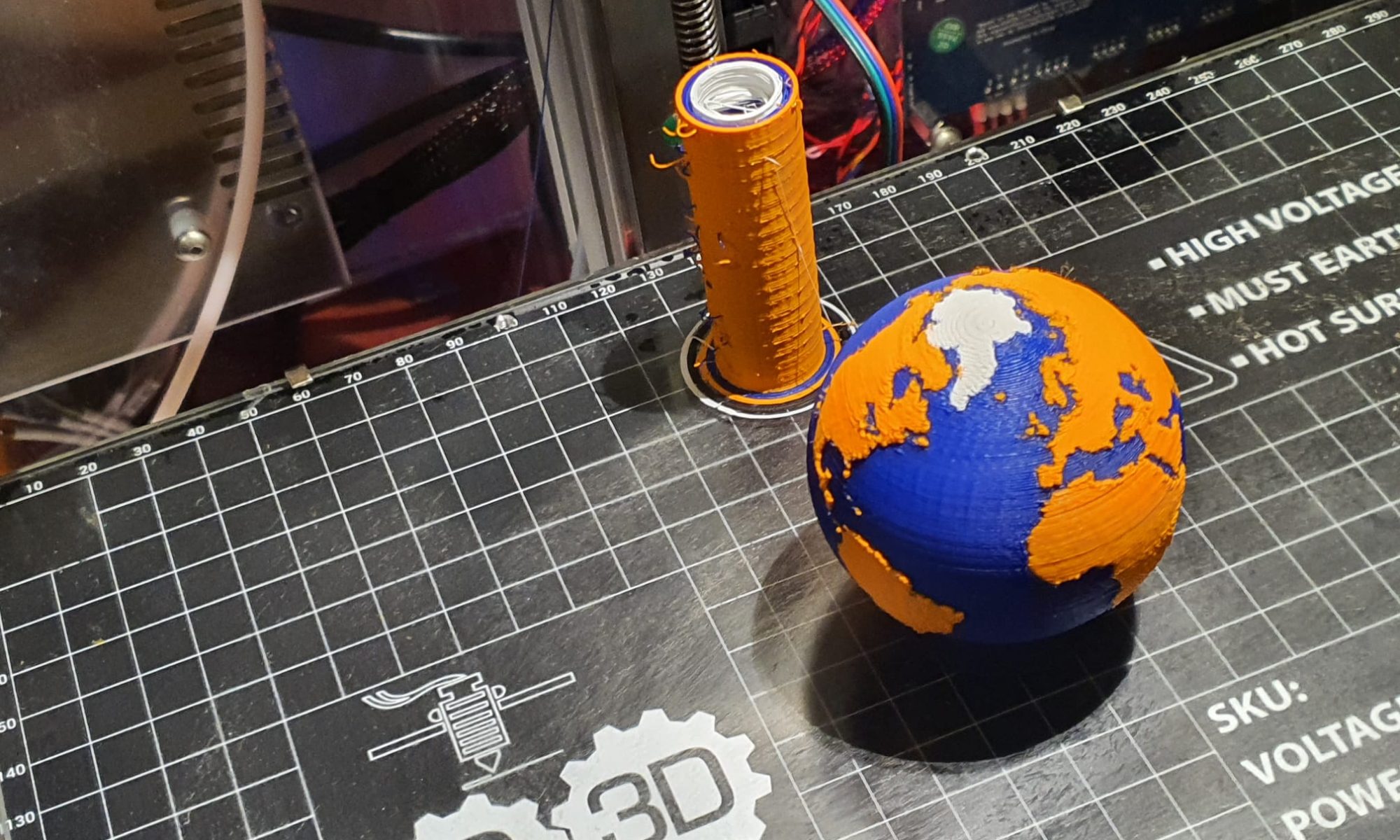

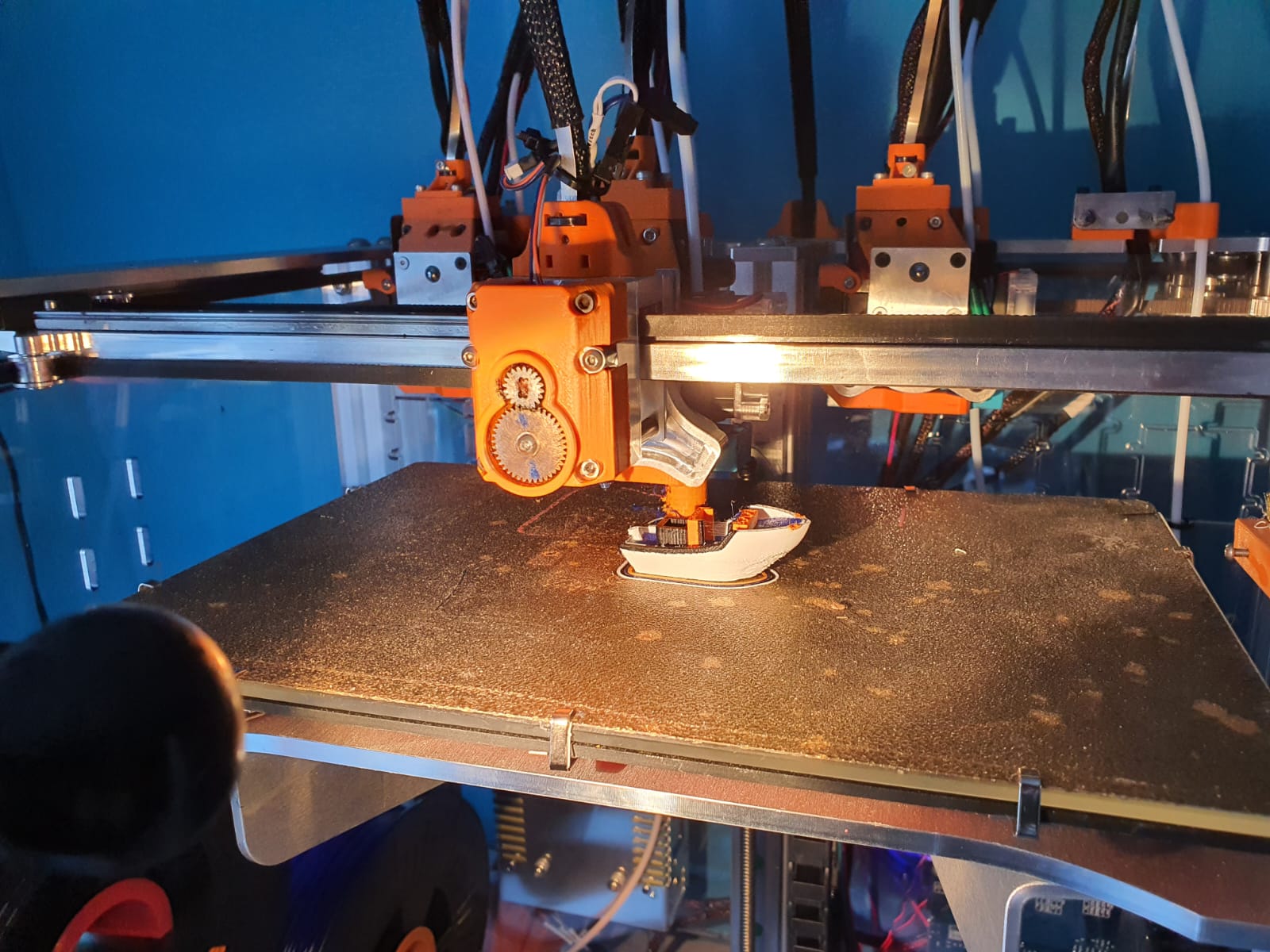

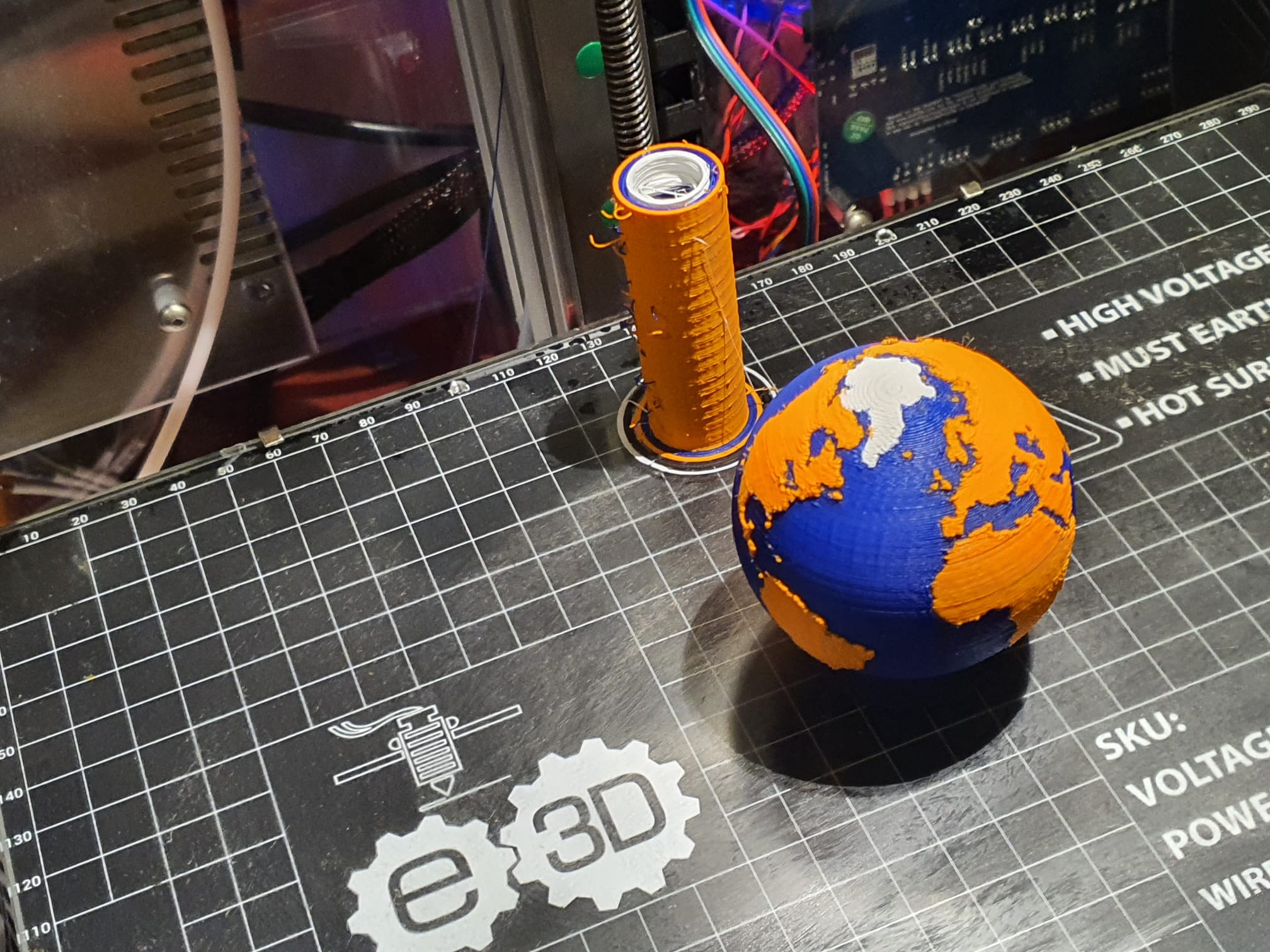

The bow of the benchy , the white right part at the bottom sags a bit.

The solution was to set the bed temperature at 10 degrees lower.

So; I now start with 60 degrees and after the first layer the bed temp goes to 50 degrees.

In addition, I flipped the benchy 180 degrees so that the cool air on the left side cools the bow better. Now it turned out absolutely beautiful!

Printed with 0.2 mm layer height and 120 mm/s!

Not perfect yet but we’ll get there!

E3D toolchanger: Tuning the tool pickups with reprap global variables and macros assistance

E3D toolchanger upgrade: X-and Y- axis homing switches installing and configuring

Building E3D coreXY 4-toolchanger 3d printer

Toolhead stepper fault and solution