2021-10-30: When converting (or upgrading, depends on your P.O.V.) a mill to CNC, it is absolutely necessary to have end stops on all ends. Except the low-end of the Z-axis, an end stop at the Z-axis low end is practically impossible.

On the Z-axis low end another solution has been established by using a Z-stop from the milling toolbit on a fixed X-Y position, OR by testing with the toolbit in place on the matrerial by sight or electronically.

I bought a Z-position sensor for this, which is nothing more than an electrically insulated round pod with a flexible brass top. It is with one wire connected to the Mach3- motherboard as Z-probe and triggers when the tooltip touches the top of the Z pod’s brass top. Therefore, this trigger is defined as ACTIVE when it is conected to Ground. Since the mill will be grounded and thus also the tooltip is always connected to ground. You MUST ground the mill, by the way. Also for your safety.

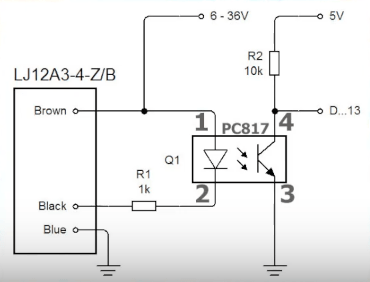

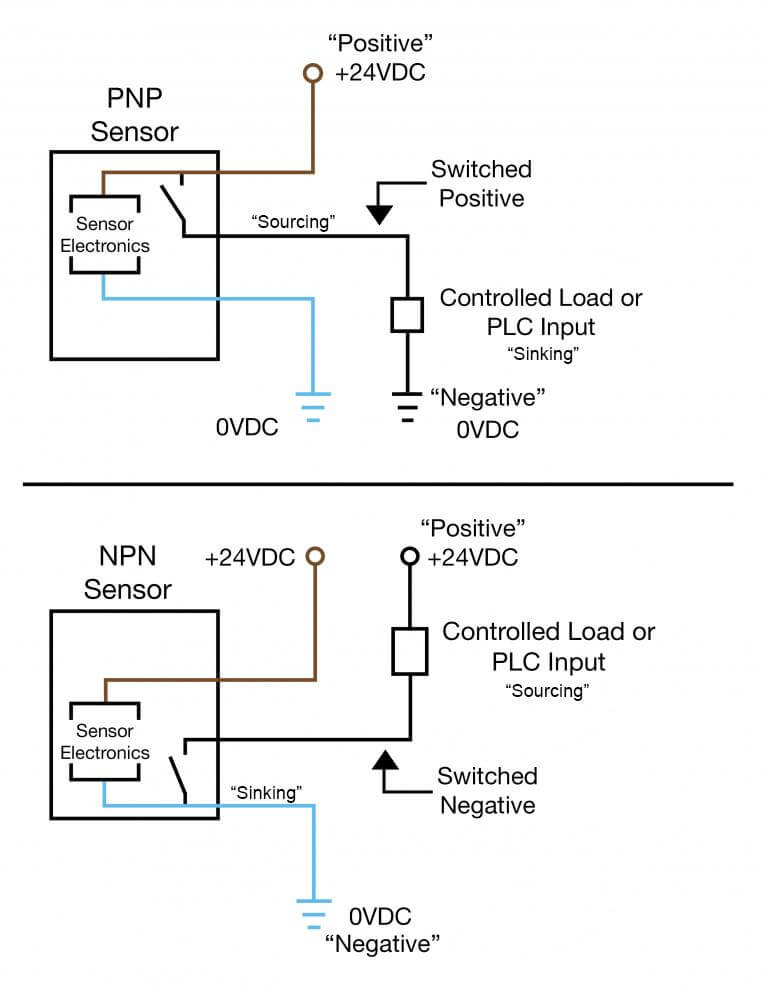

Leaves us with the 5 enstops for which I have bought the thinnest available inductive sensors. These are M6 size round and about 8 cm long. These sensors require power, ground and since they are NPN type sensors which means Normally OPEN when NOT active, they will ground the output pin when activated at reaching the the stop position. To activate these inductive sensors, a carbon- containing metal would be best to use and bring the sensor close. The trigger moment depends on the connected power voltage. The higher the voltage, the more sensitive the sensor becomes.

I will use 12 Volts or 24 Volts, I will experience a bit with these settings.

On the net I was unable to find any plug and play sensor holders for my mill, so I developed these holders again from scratch in OpenScad.

Fortunately, I have a lot of starting material in OpenScad from my previous projects.

The X axis left:

The X axis right hand side:

The Y axis front:

The Y axis rear:

The Z-axis top: