I am in the process of developing a router for my plasma cutter, since the cutter works very good but it will be way more effective once I can machine my designs with a router for this cutter.

My design differs from others because i will use only existing affordable parts that require no additional machining.

Firstly, you would need a cutting table with a maze where you can put your steel on, when cutting. This maze will be enclosed with a steel box so no cutting debree will be thrown around. Around the box a set of aluminium or steel profiles will be mounted on which the wheels for the X or Y axis will be built. From here on, a normal router setup can be made.

The plasma head will need to be adjustable in height but does not neccessarily need to be CNC movable. Just a manual knob to move it up and down a little will do.

So, only 2 axis are to be made with CNC.

For the Y axis I will use a complete accessory from AliExpress with ball bearing 1604 and an effective way of 600mm, including a Nema23 stepper motor.

The plasma cutter ‘head’ will get a fixed (but a bit vertical movable) mount on the mounting plate of the Y-axis.

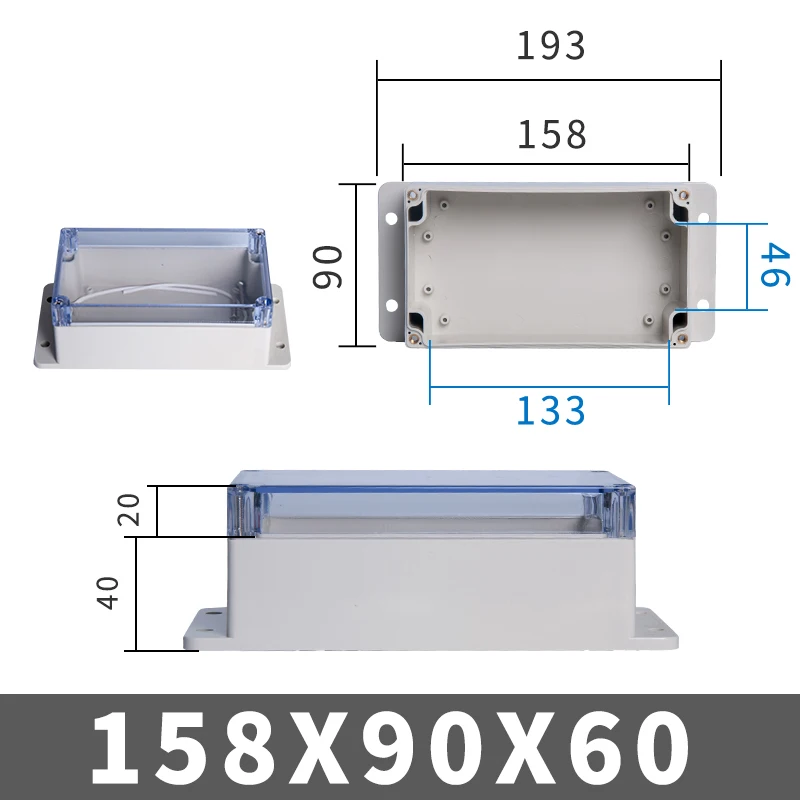

The electronics will be added at the front of the Y-axis in a 3d-printable box. (or you can buy a ready-made box HERE).

Electronics will be an Arduino UNO with standard GRBL shield, or THIS as a better all-in one solution, including local router managing. At the beginning and end of each axis, a limit switch will be mounted. Switches, cabling and mounts are available on Aliexpress HERE and HERE.

Firmware for the Arduino comes from the widely available GitHub and the GRBL community. GRBL software is available for Windows PC and MAC as well. Designing can be done in any way, and the most simple way will be the online Cad solutions like Tinkercad .

The power supply for the Plasmarouter will be a 24 Vols 8 Amps portable power supply like THIS one.