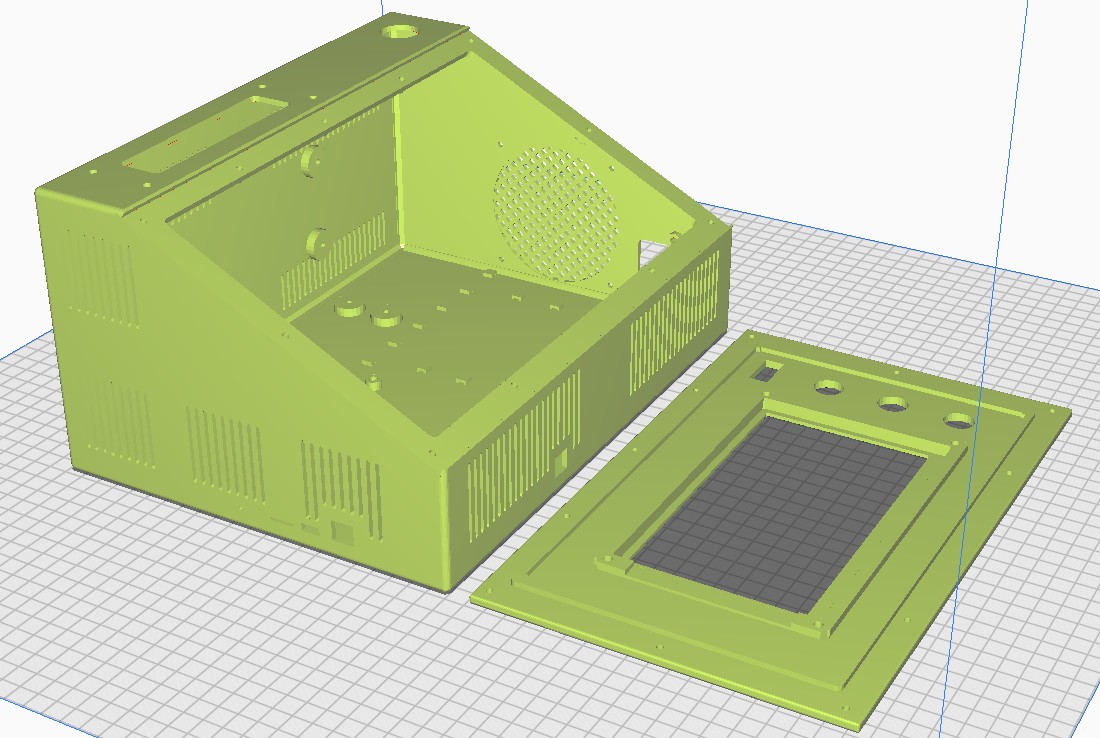

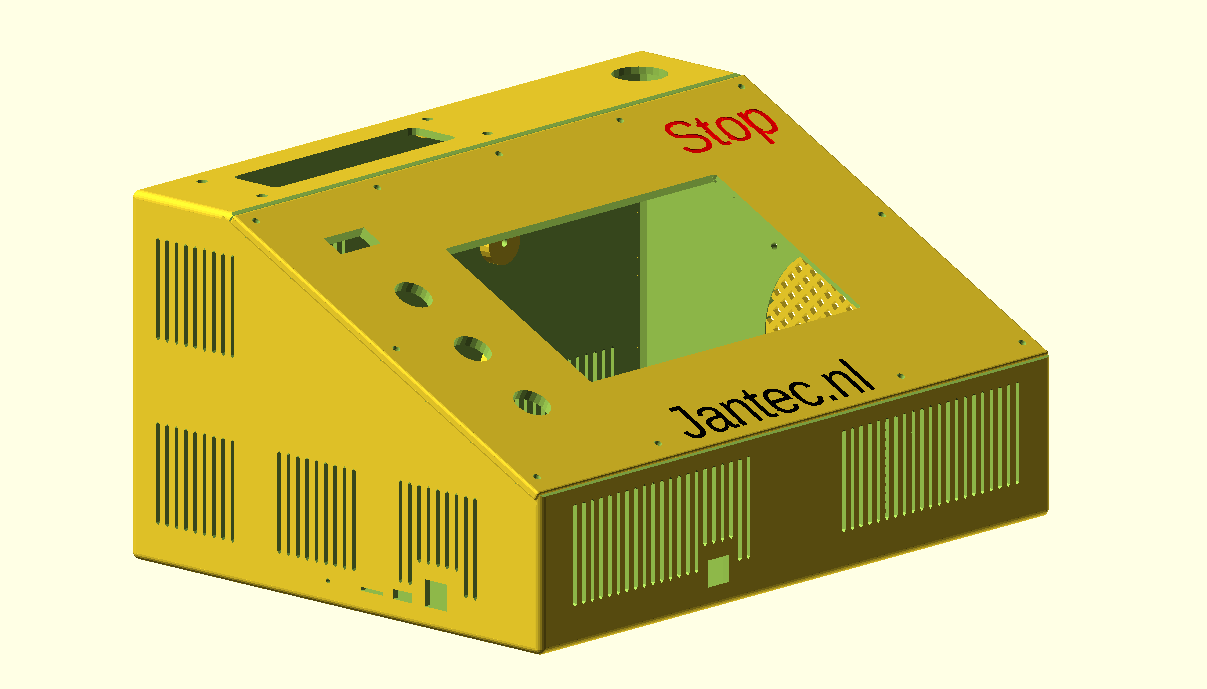

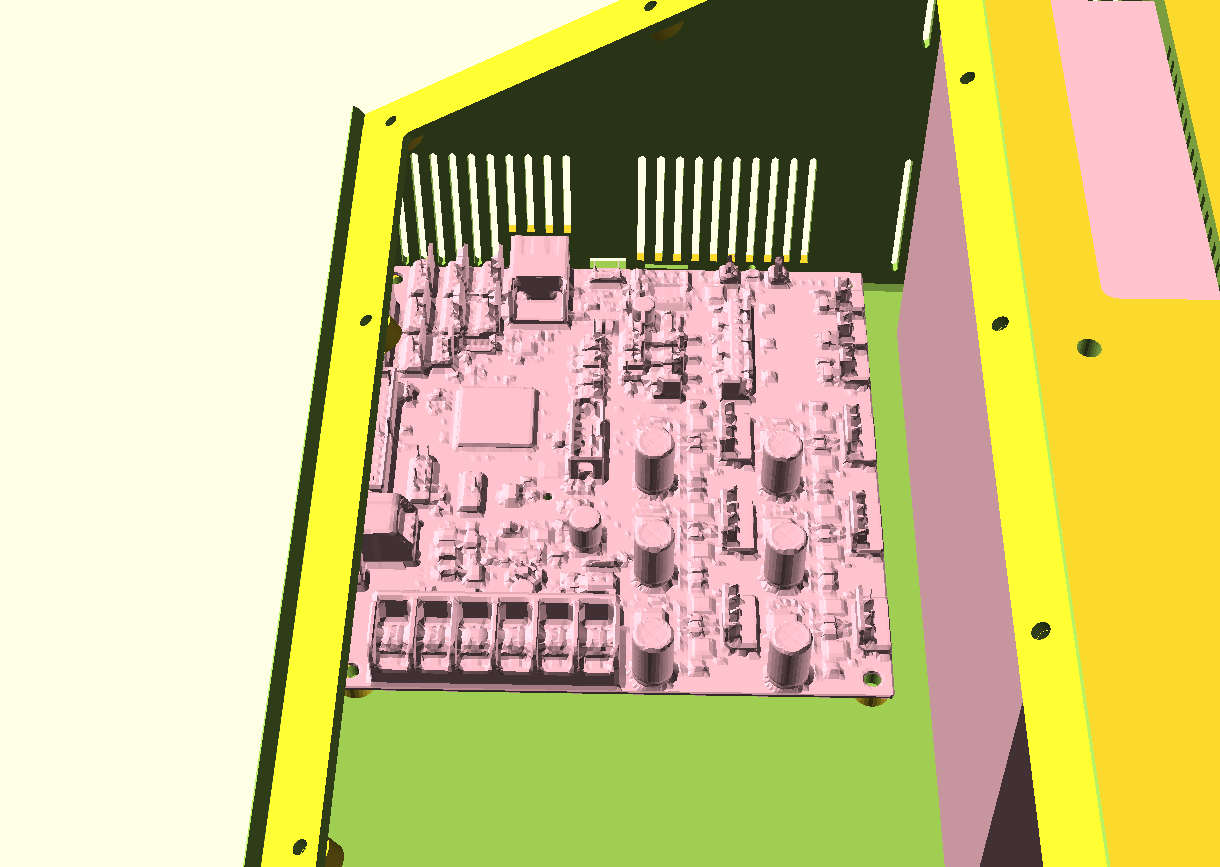

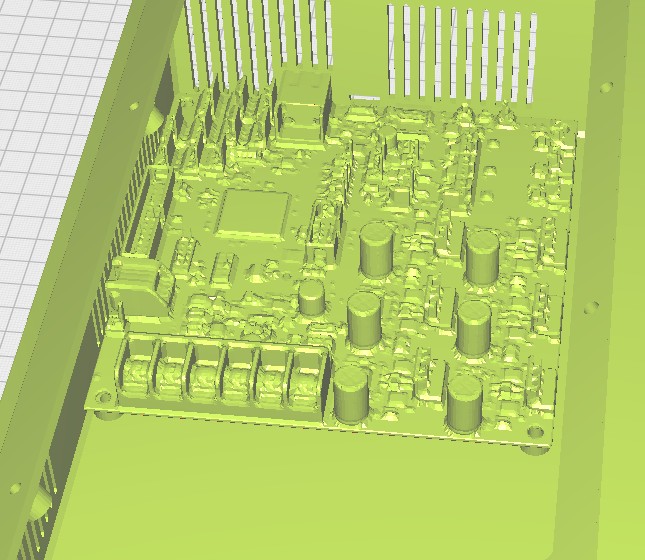

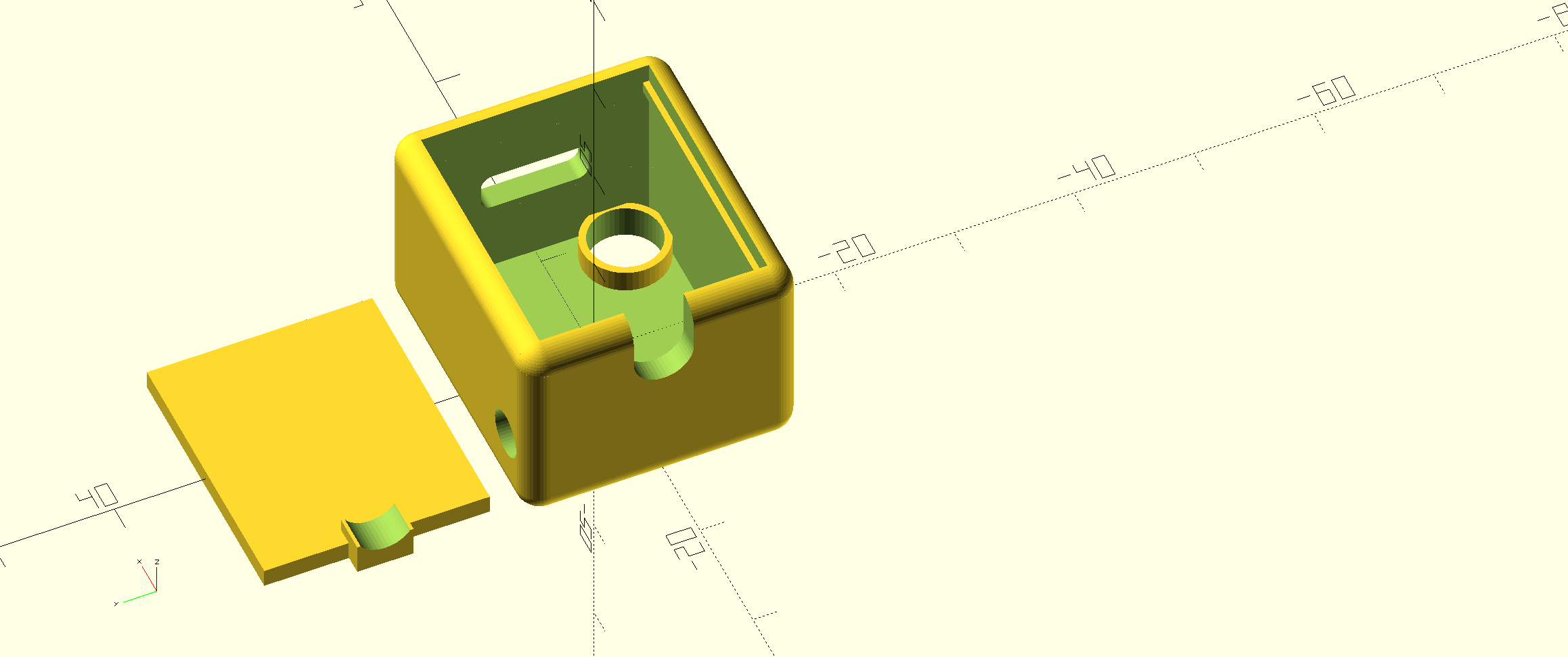

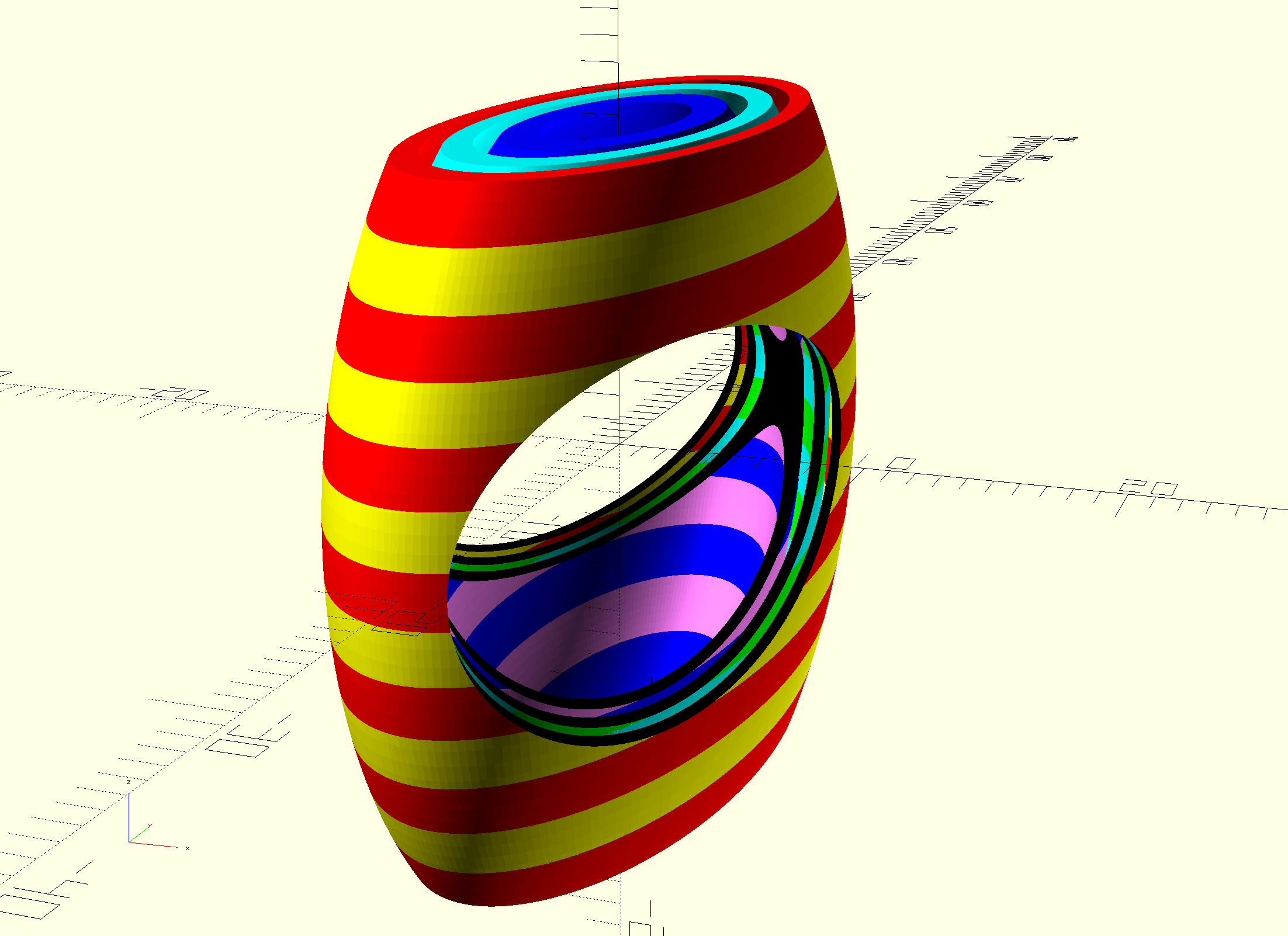

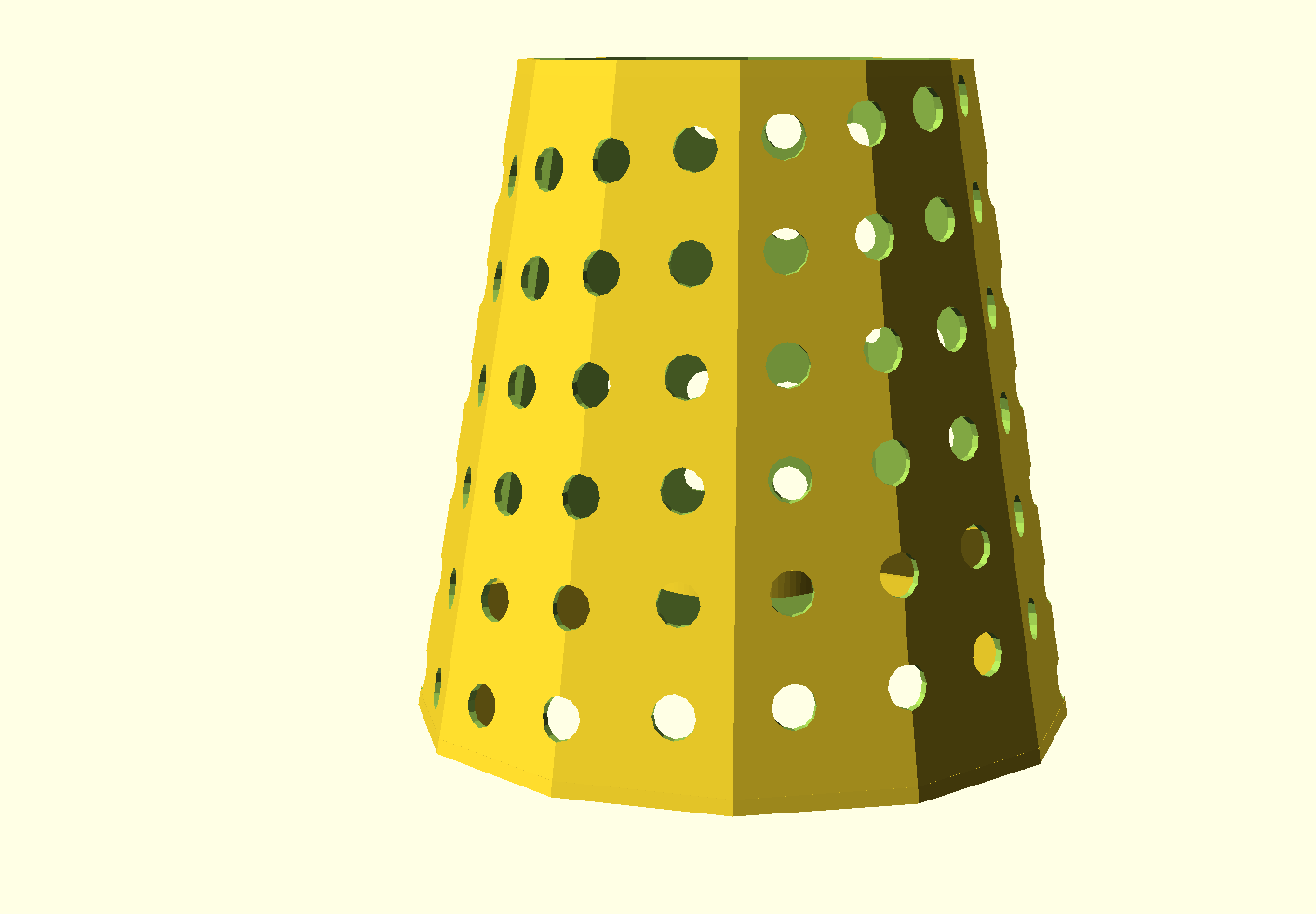

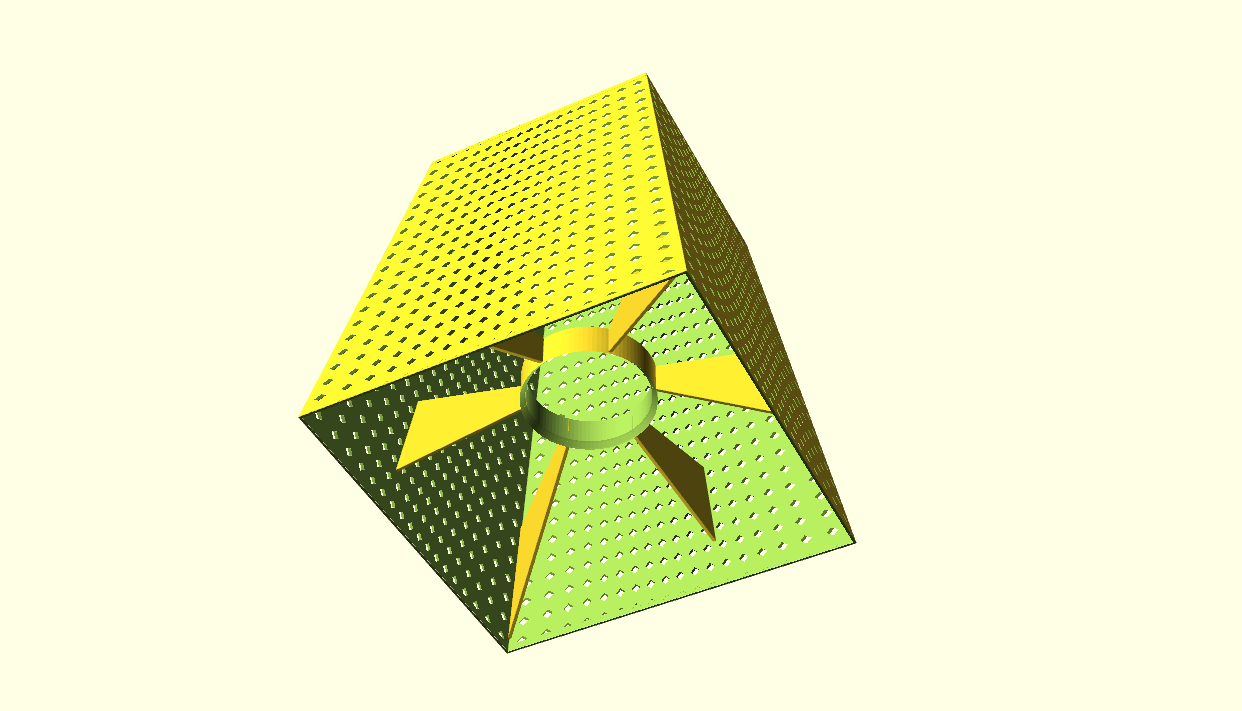

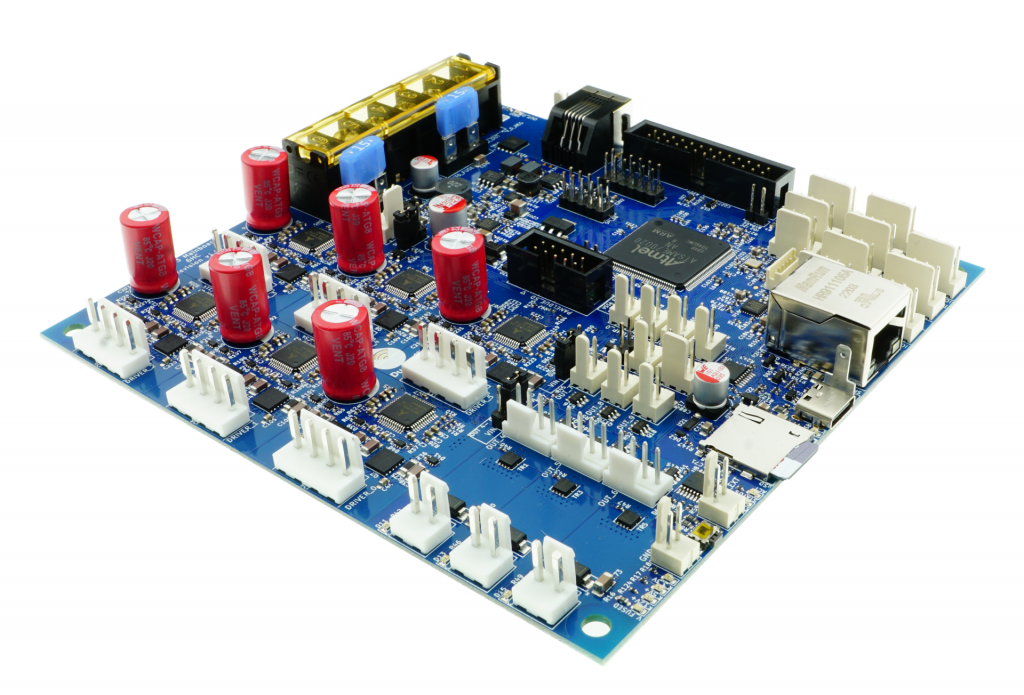

Due to the DUET3 control board’s size, it does not fit into the previously developed CNC housing for a FLY_CDY board, so a lot of modifications had to be made. This resulted in the preliminary (V13) OBJ design which can be downloaded HERE (20250604)

This post has the published last version with tight fits for the DUET3 6HC motherboard, the 24V PSU and so on.

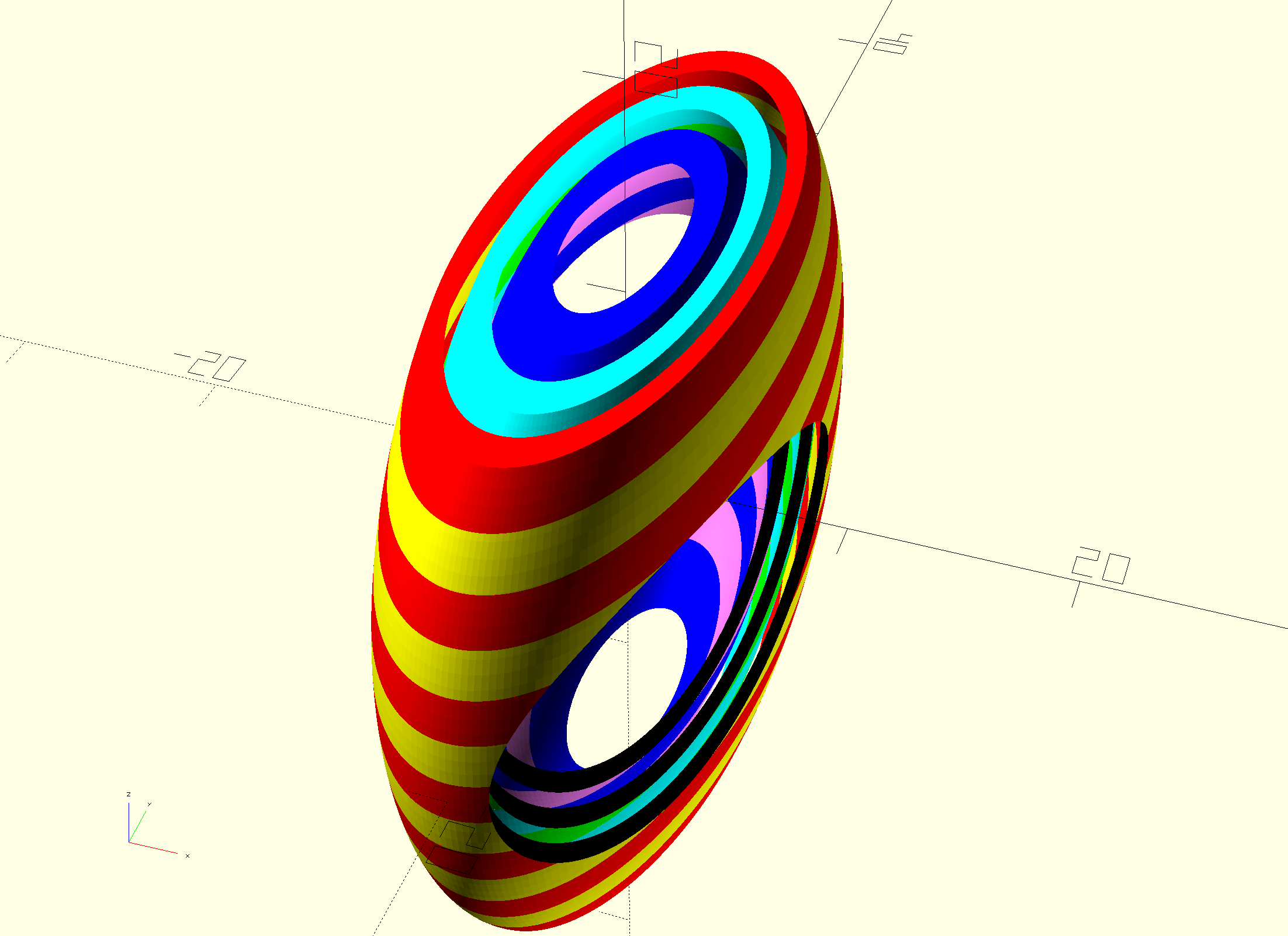

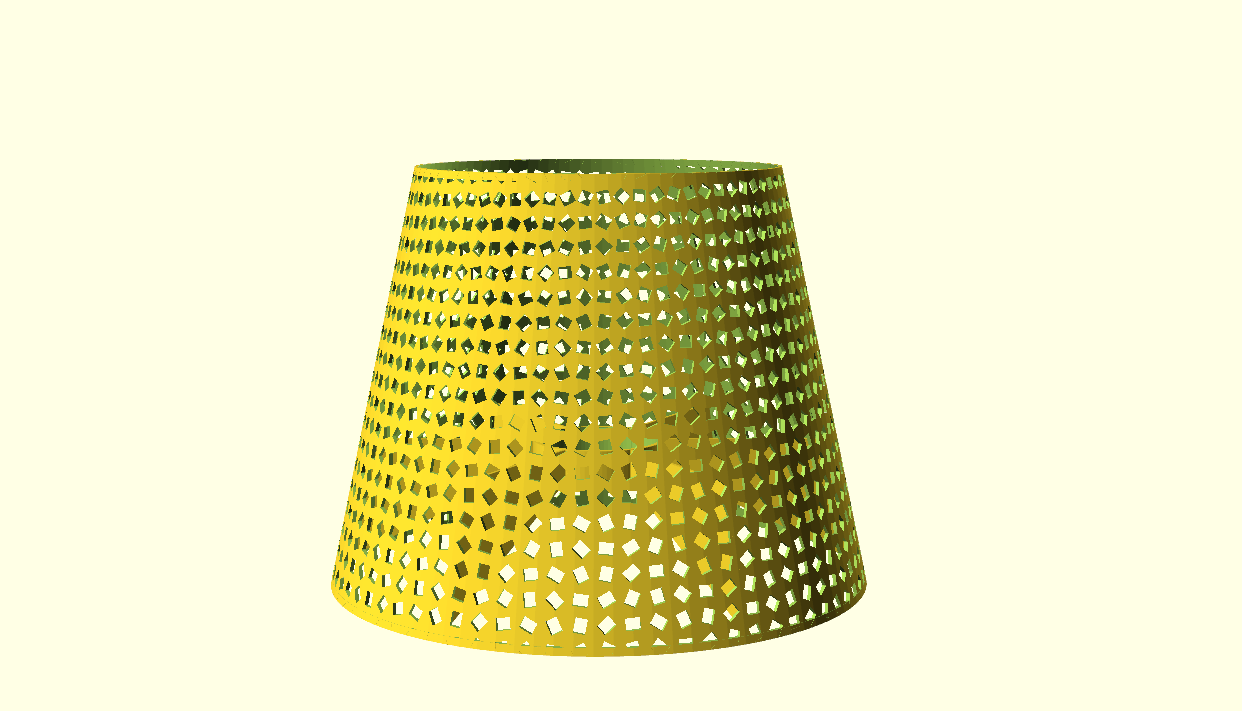

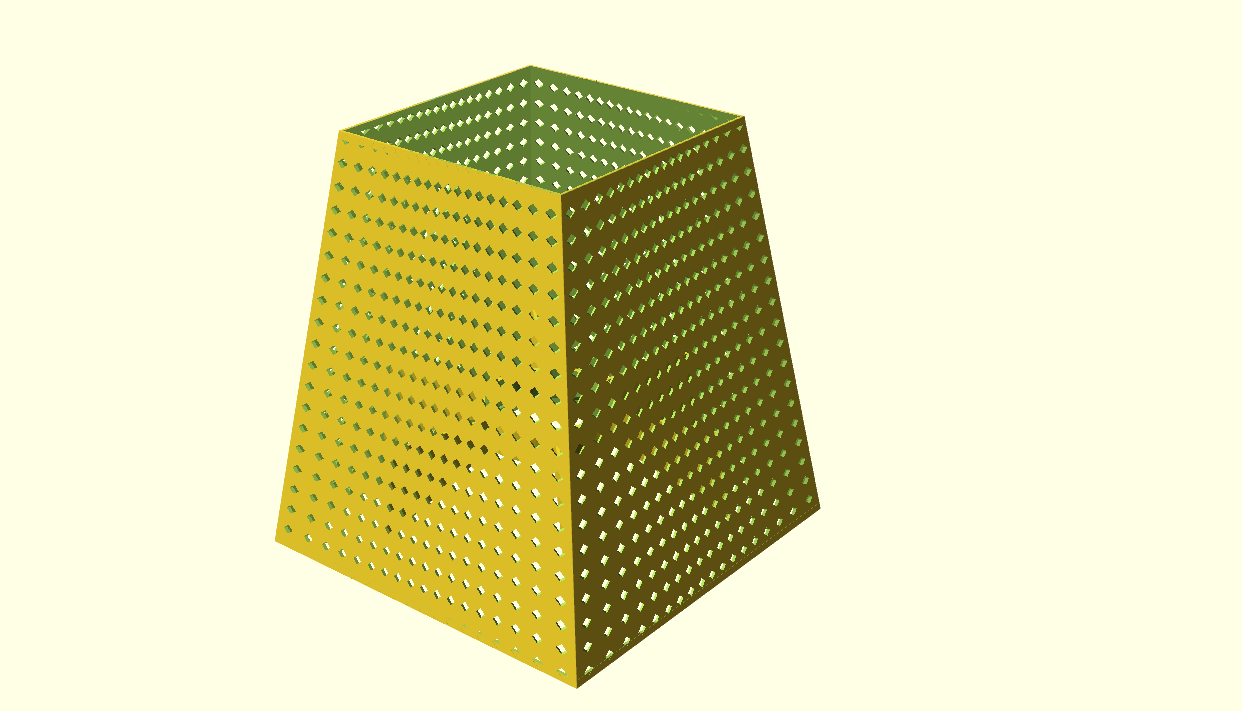

The dimensions of the newer DUET version are smaller than the peliminary DUET3 version. Now, the dimensions are made the same as the CNC controller box that I made earlier for the Mellow FLY CDY2 or -3 motherboard and DUET Workbee, DWC LCD controller from FysetC and so on.

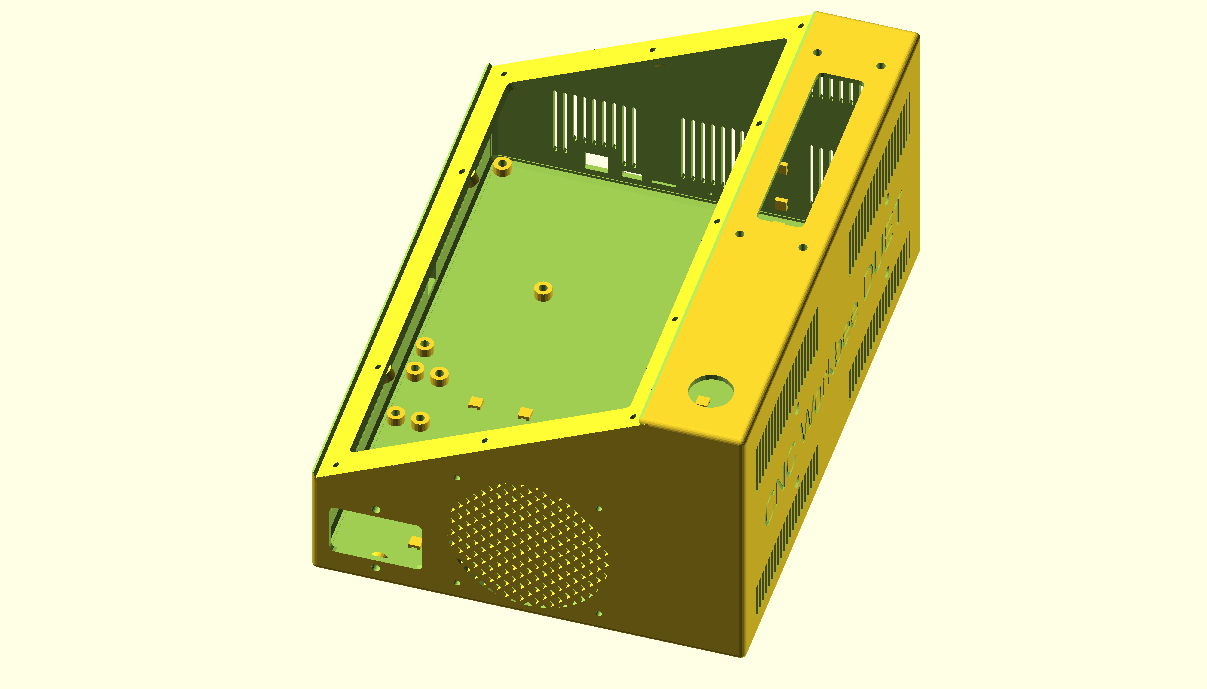

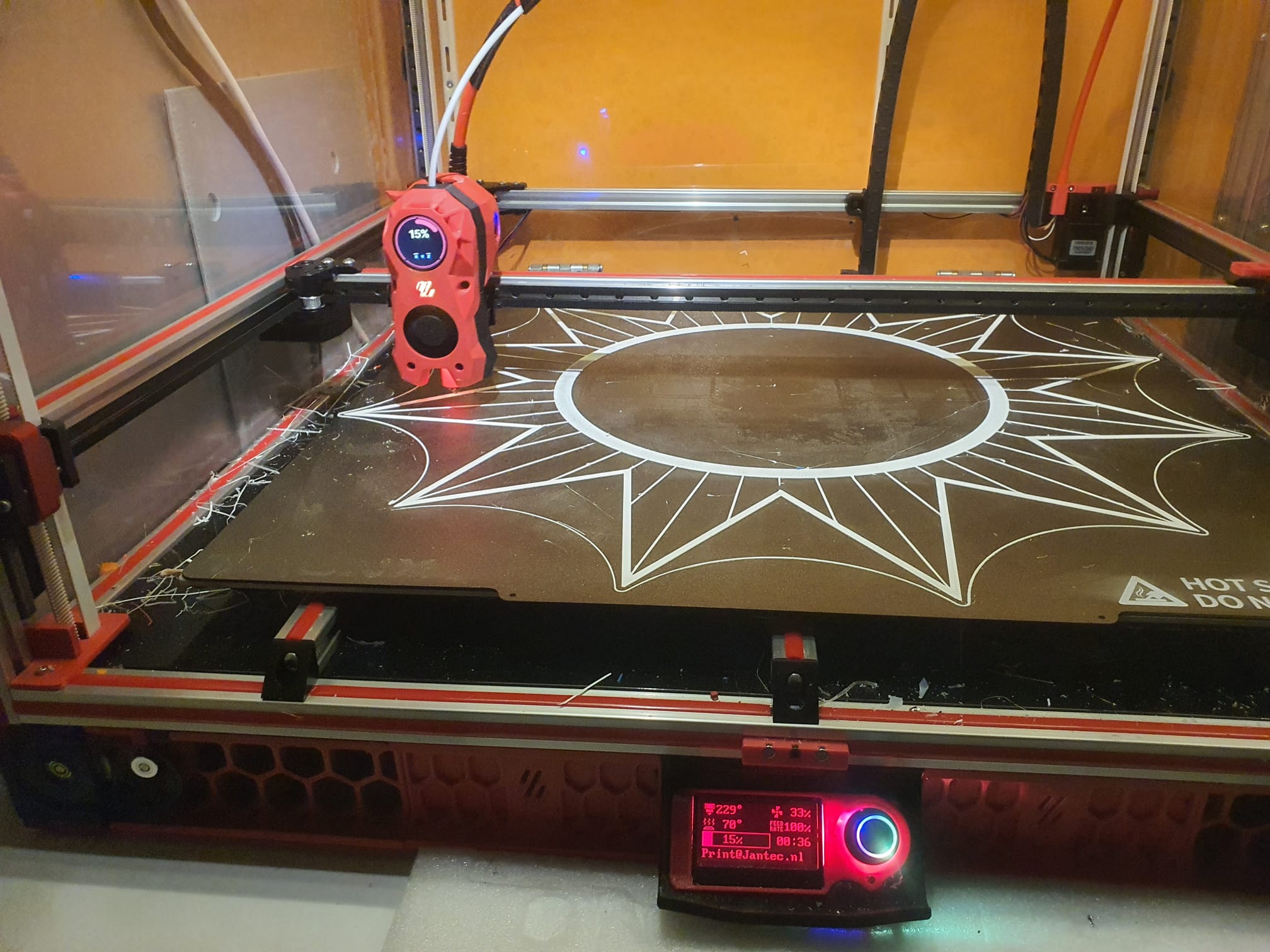

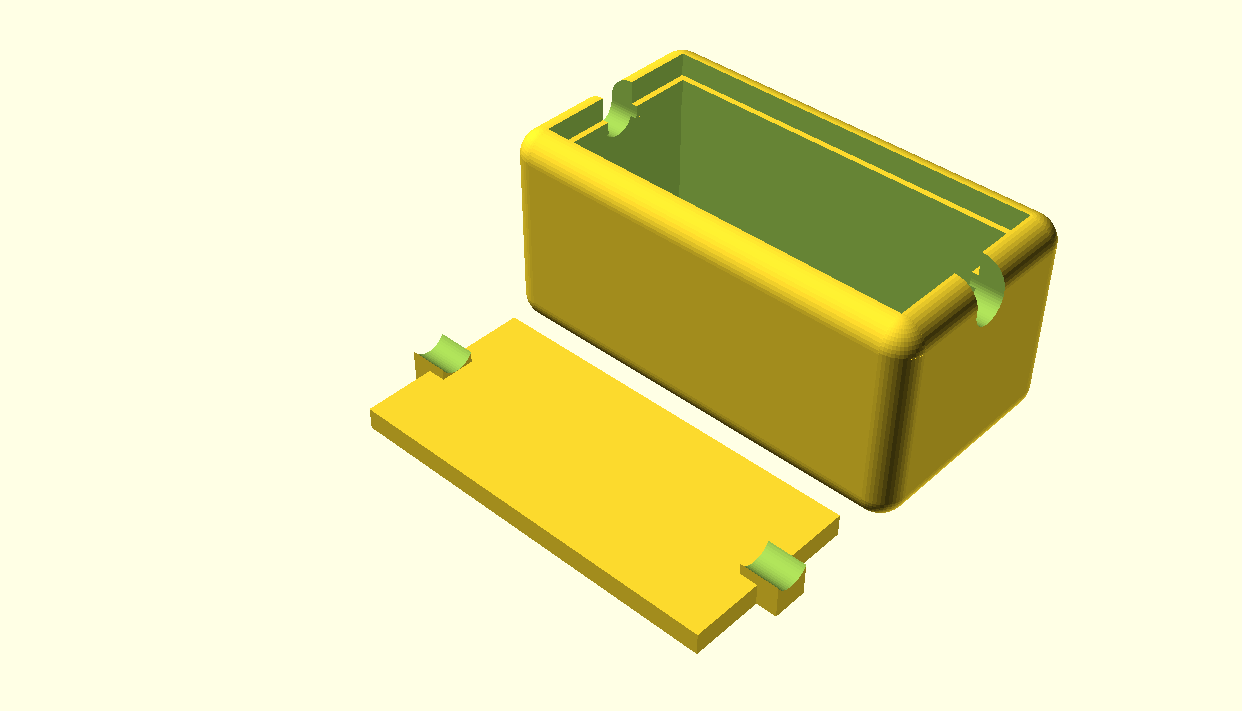

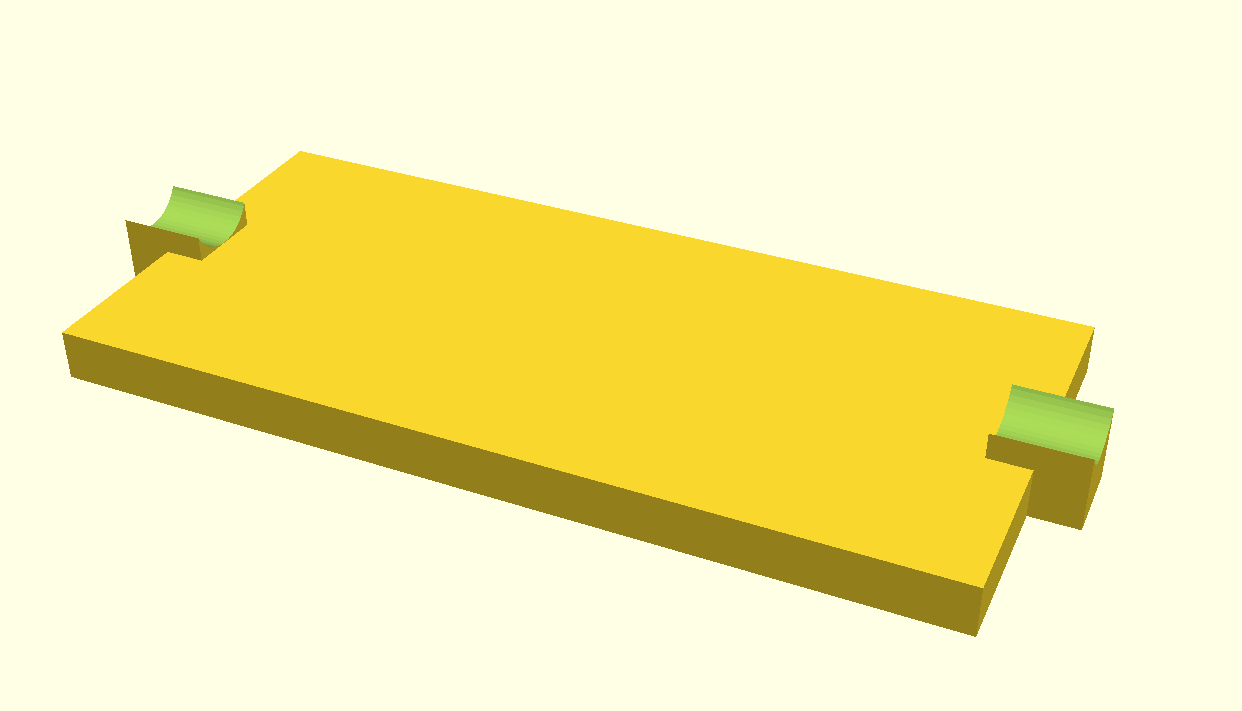

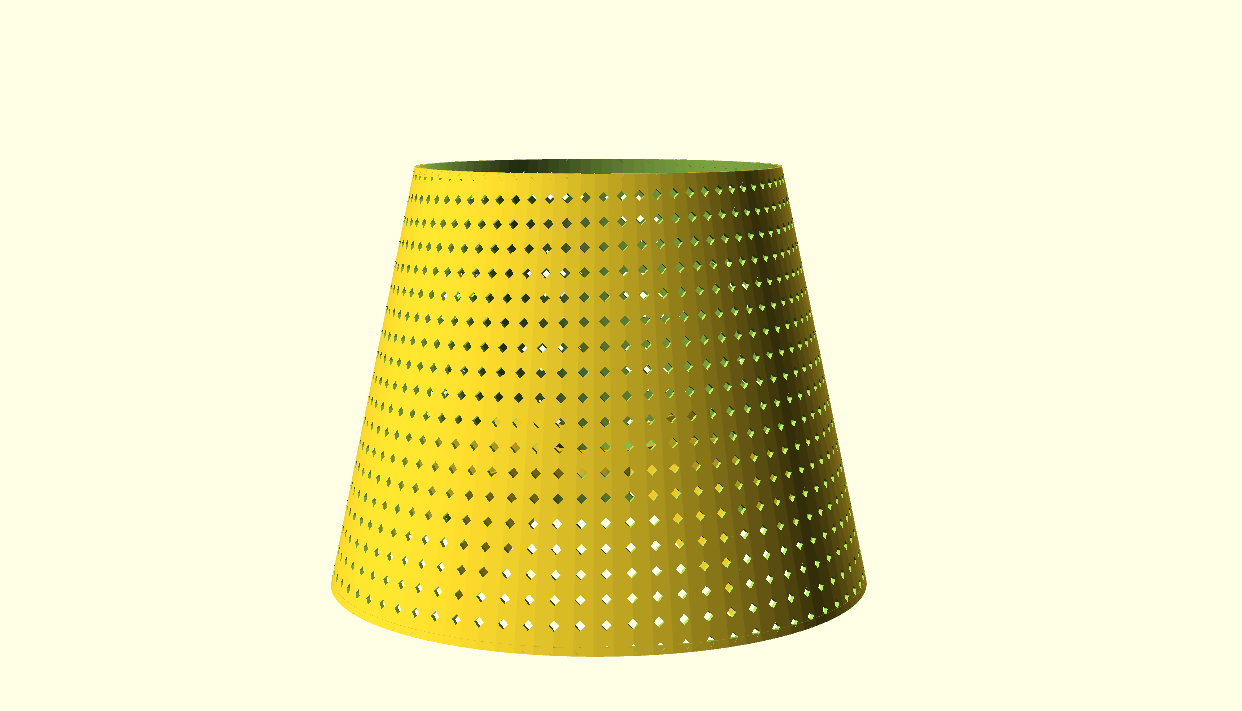

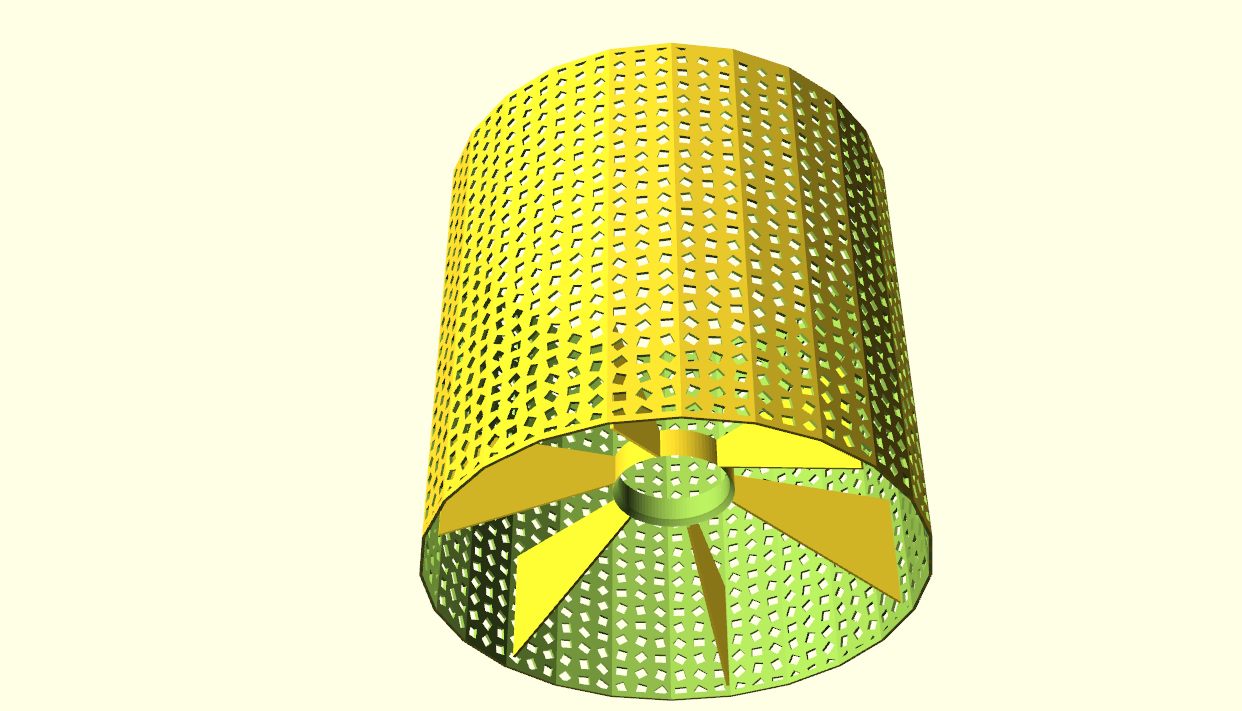

By now, I also have a workable 7-part release for this DUET3 6HC CNC controller box.

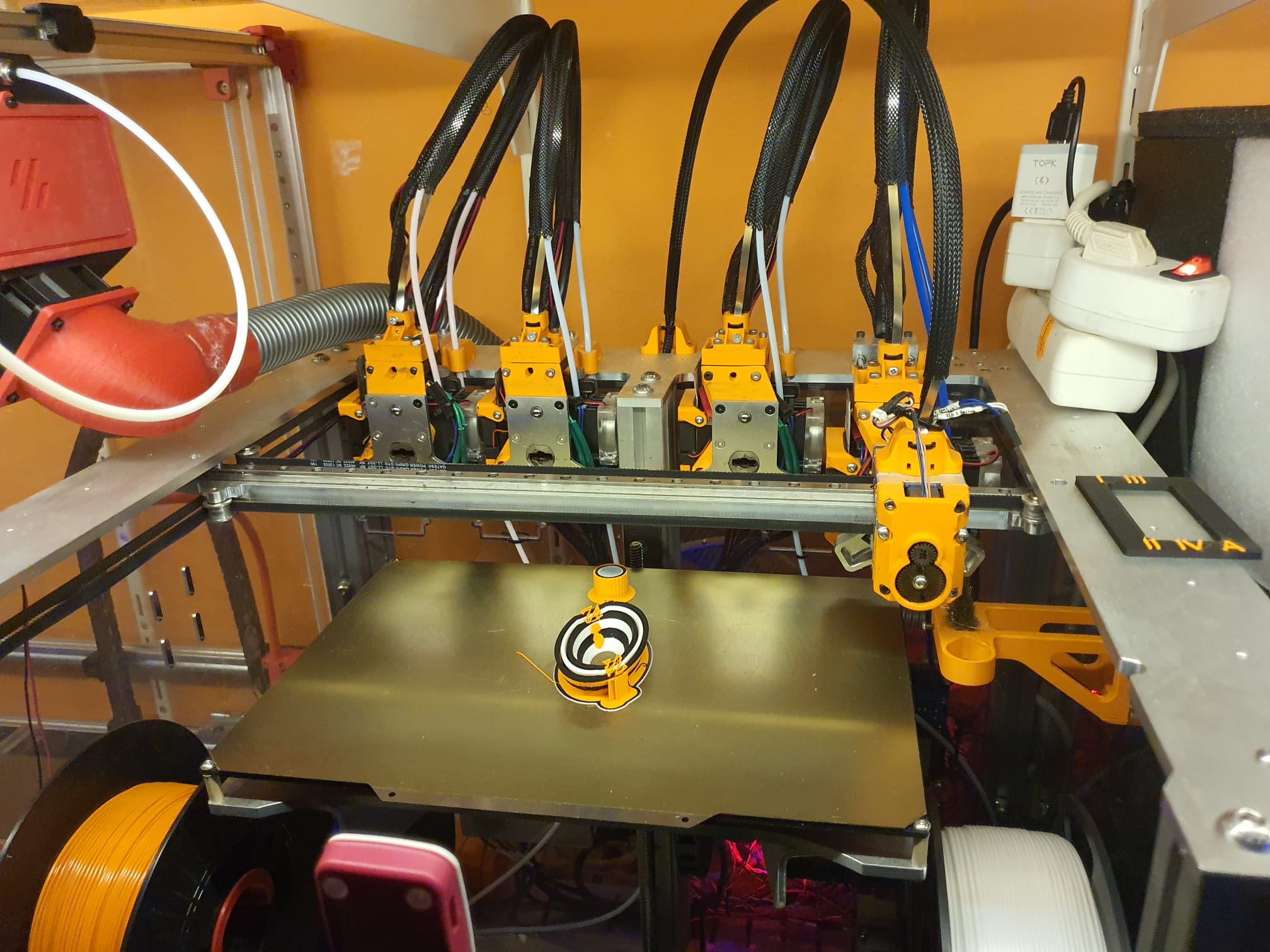

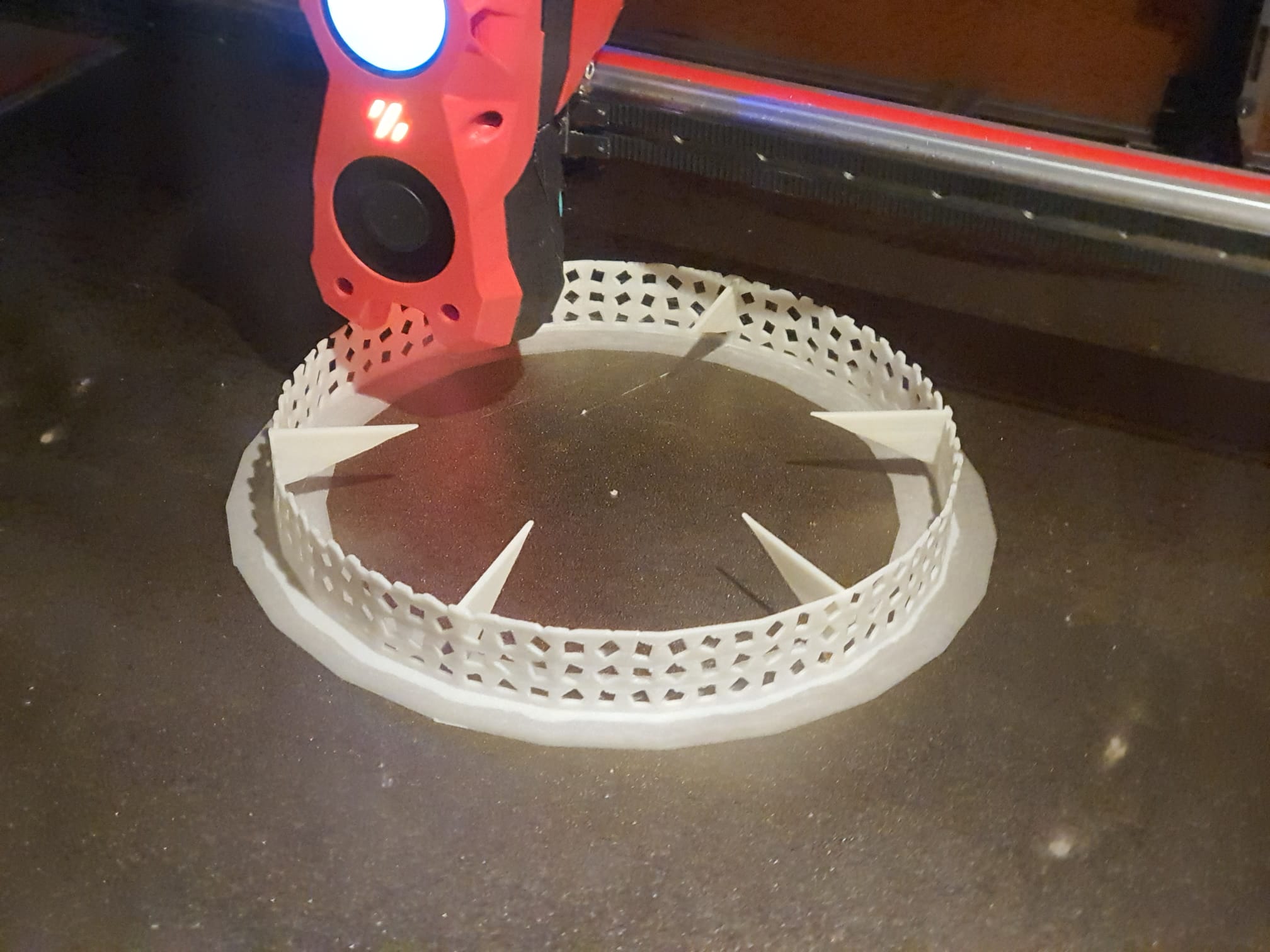

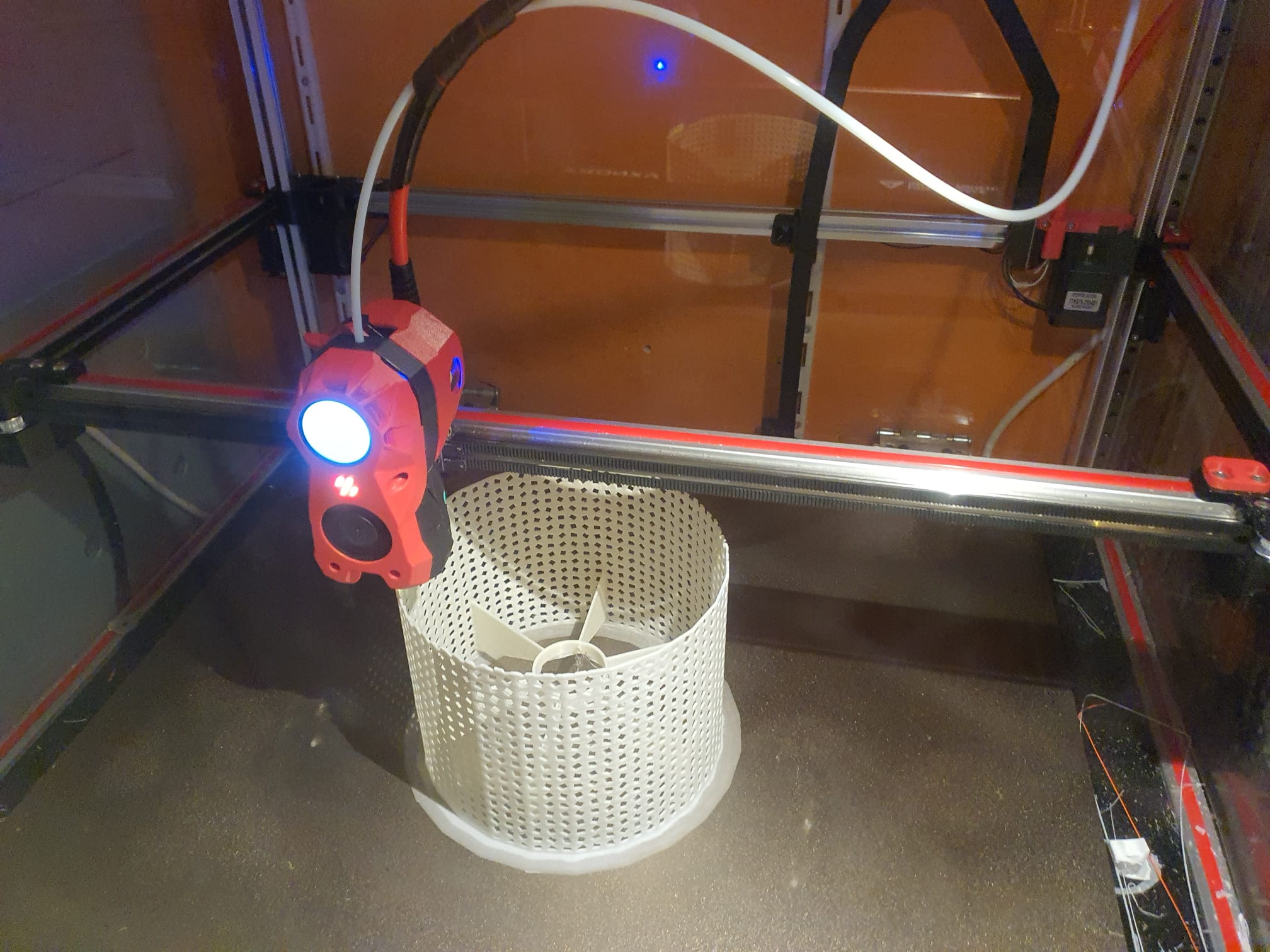

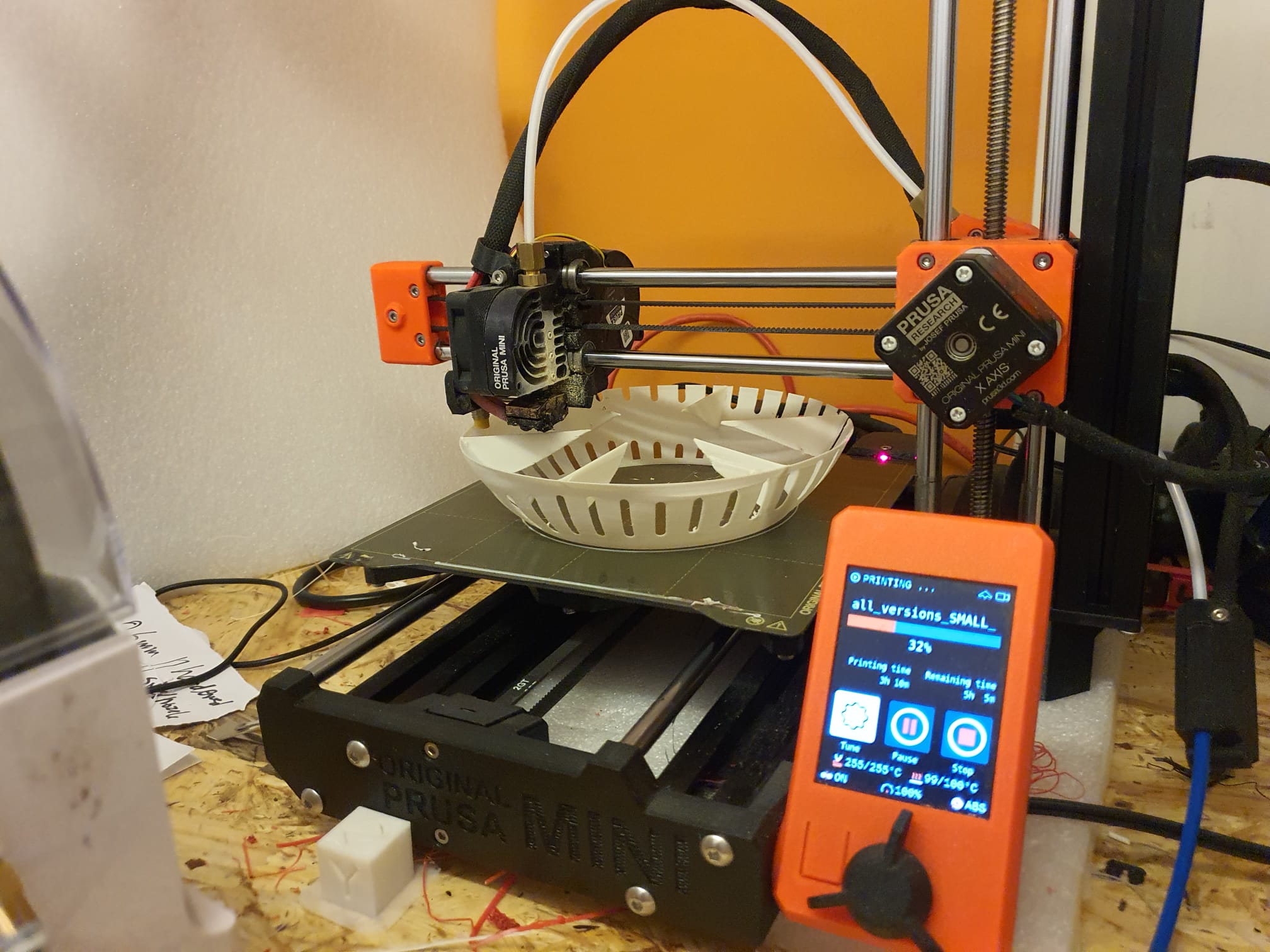

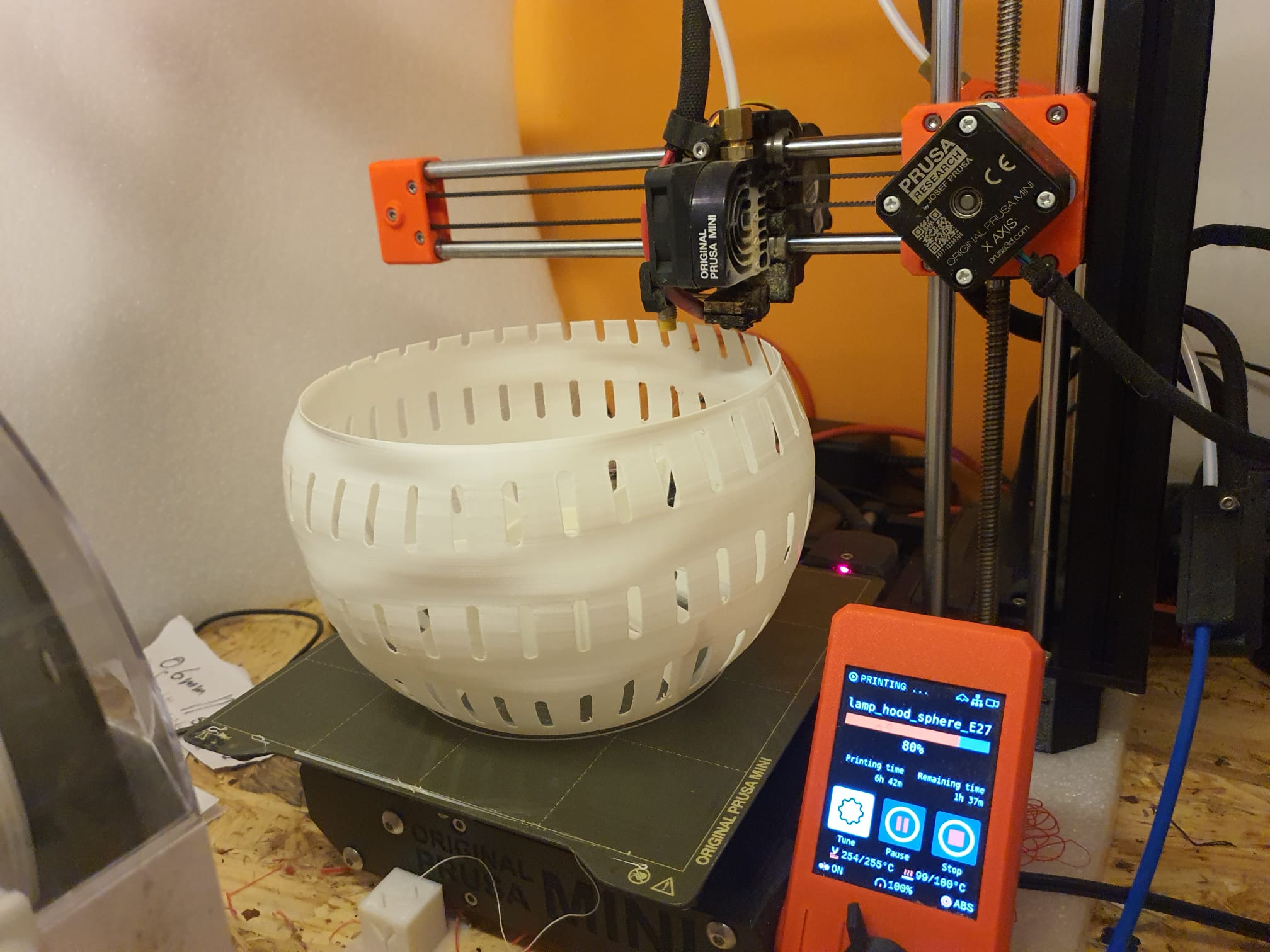

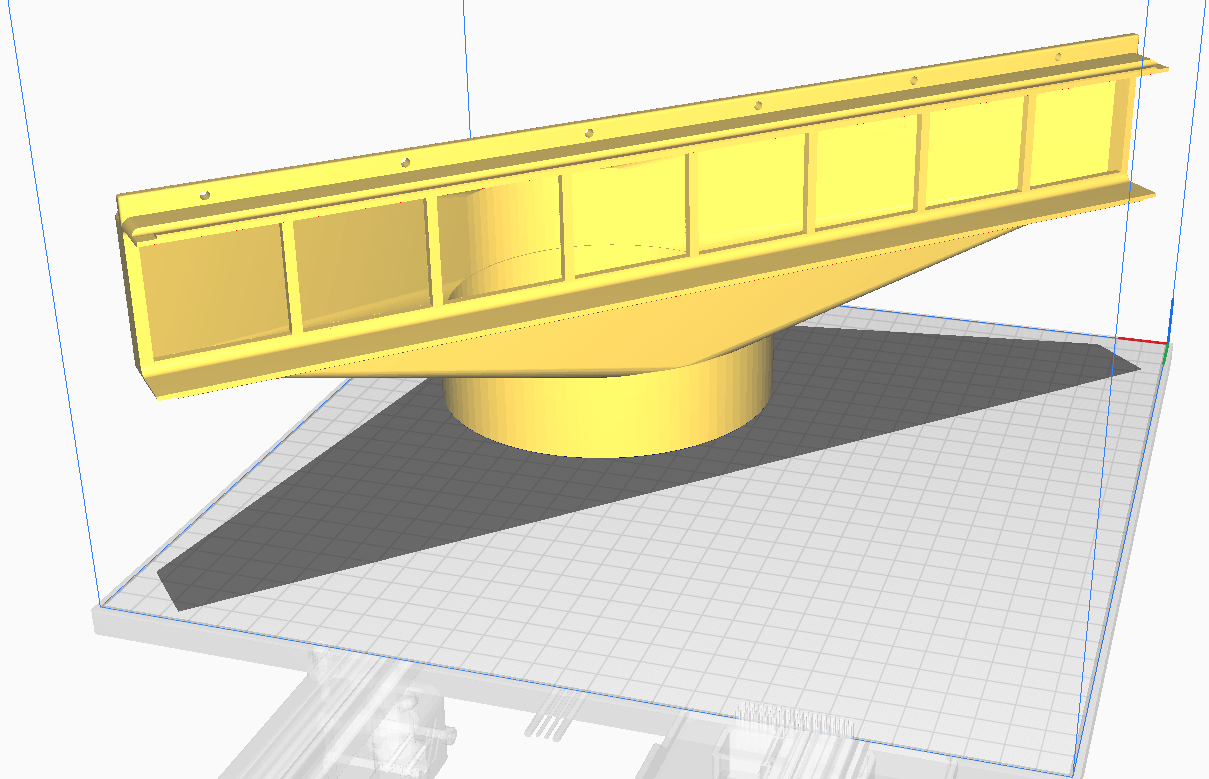

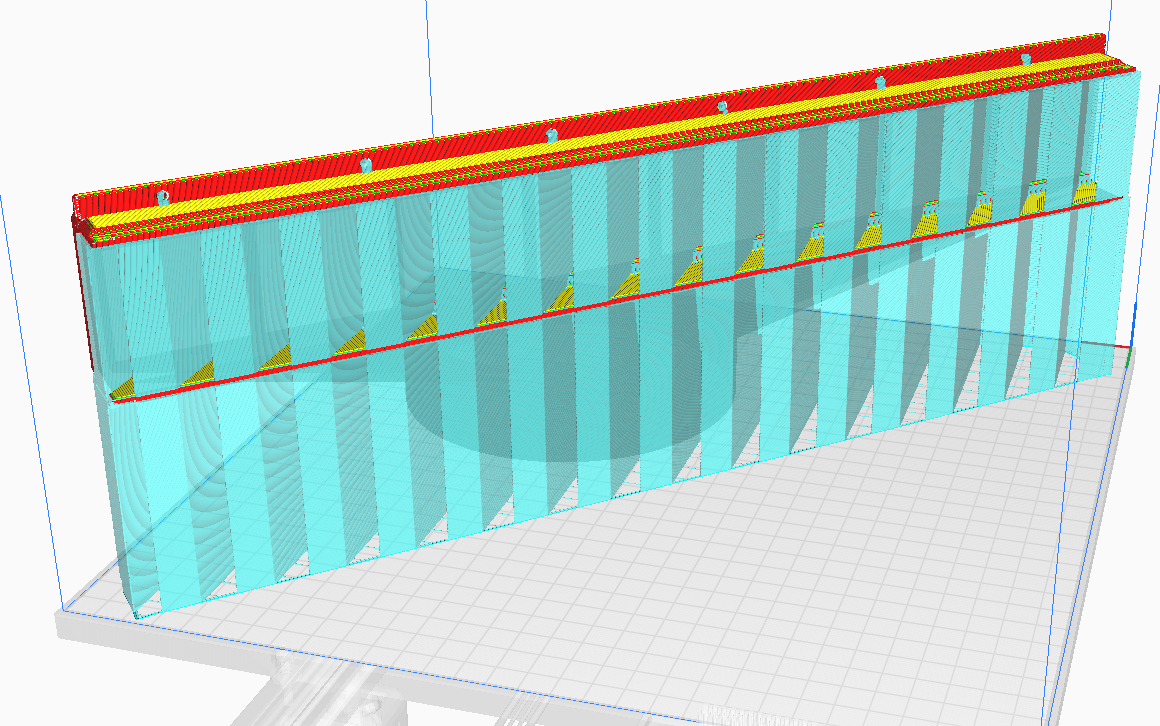

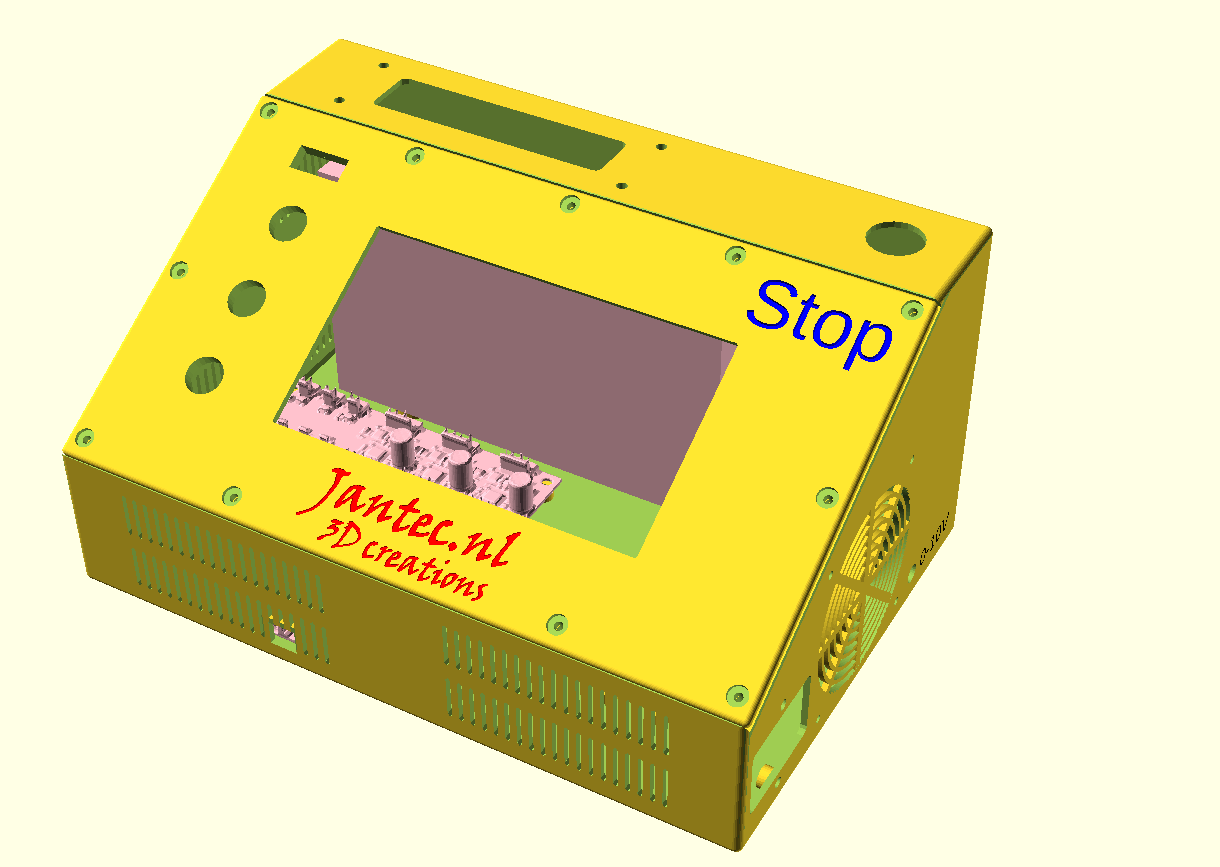

To print this 7-part version, you will need a 3D printer that has a minimum 300 mm span width of it’s printbed.

I found it a lot easier to print the controller box in 7 separate parts than in one big print-run for just the box of around 1 1/2 day which uses 940 grams of filament.

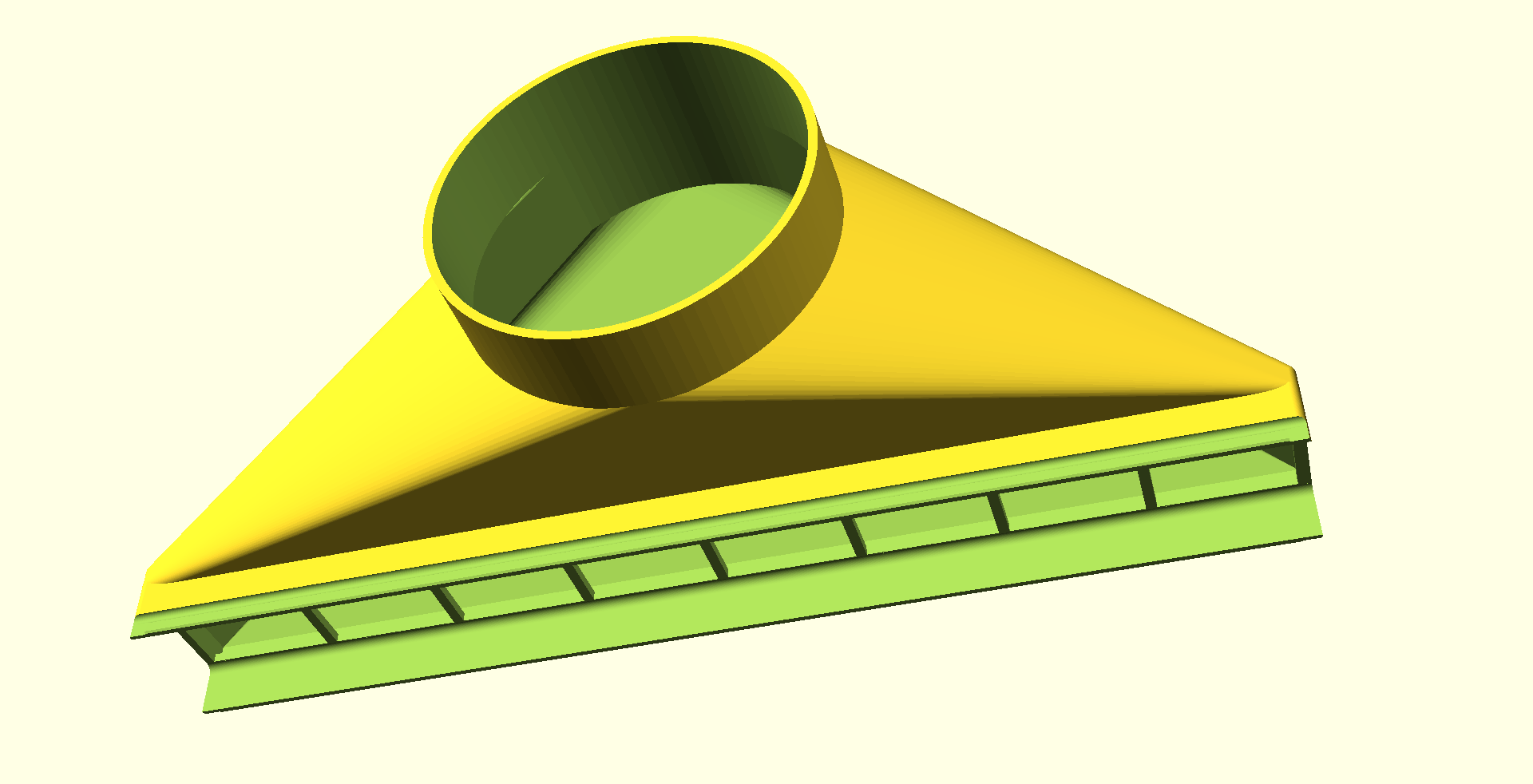

The box and faceplate for DUET3 6HC is available as:

- The old preliminary (V13) OBJ design HERE (20250604)

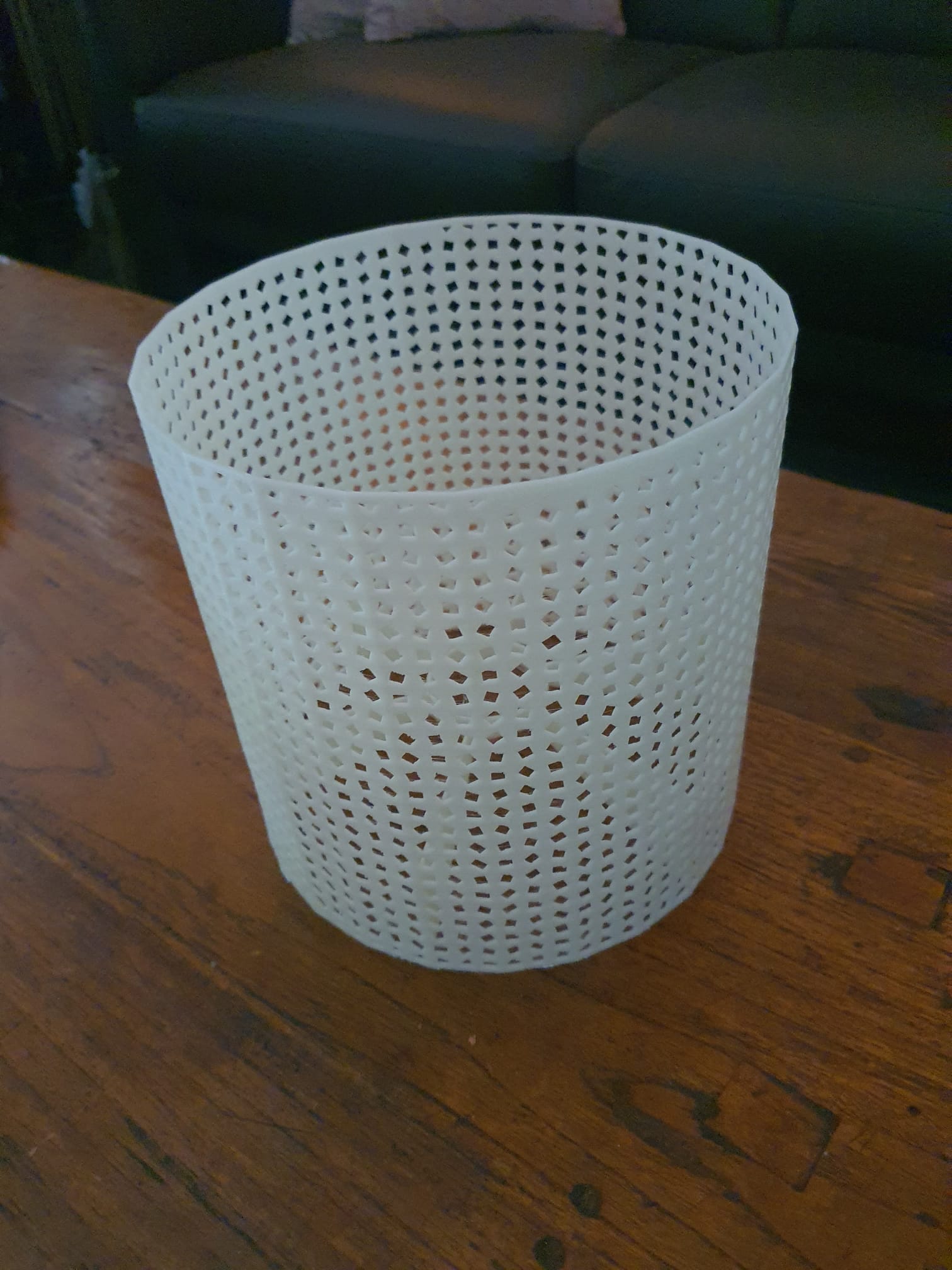

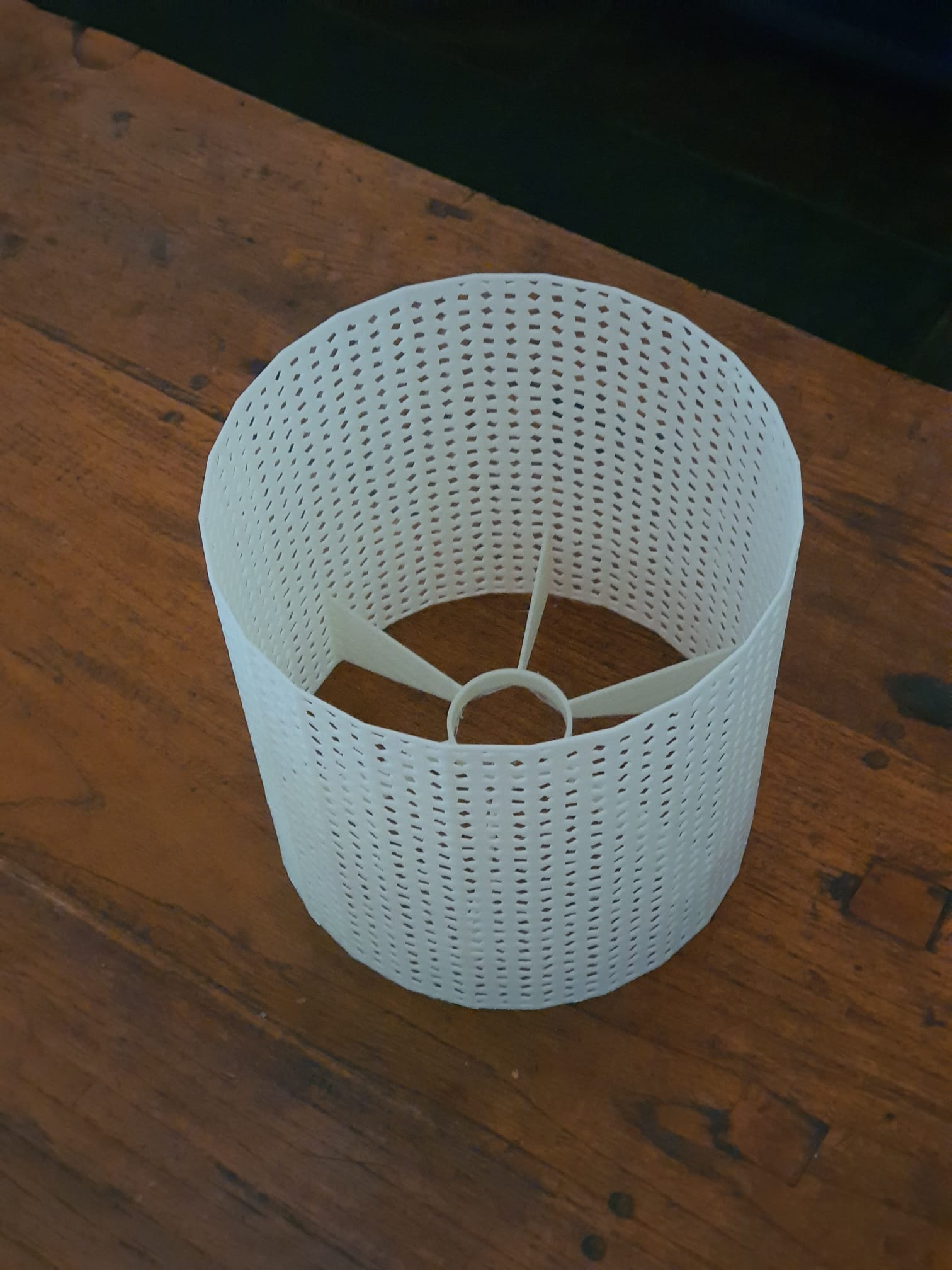

- The LAST available STL is available below for the BOX in 1 piece

CNC_controller_box_simplified_1_part_V20_FINAL_MOTHER_DUET3_6HC_BOX_ONLY_C)JANTEC.NL_20251108

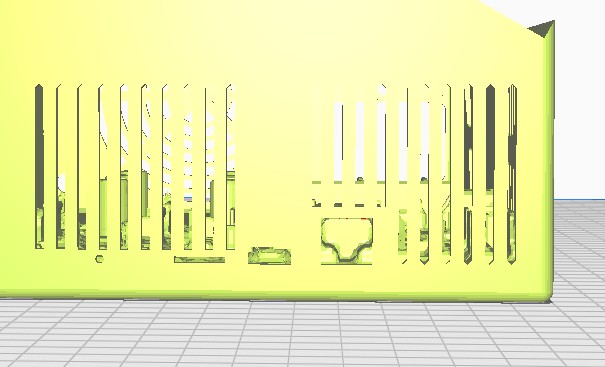

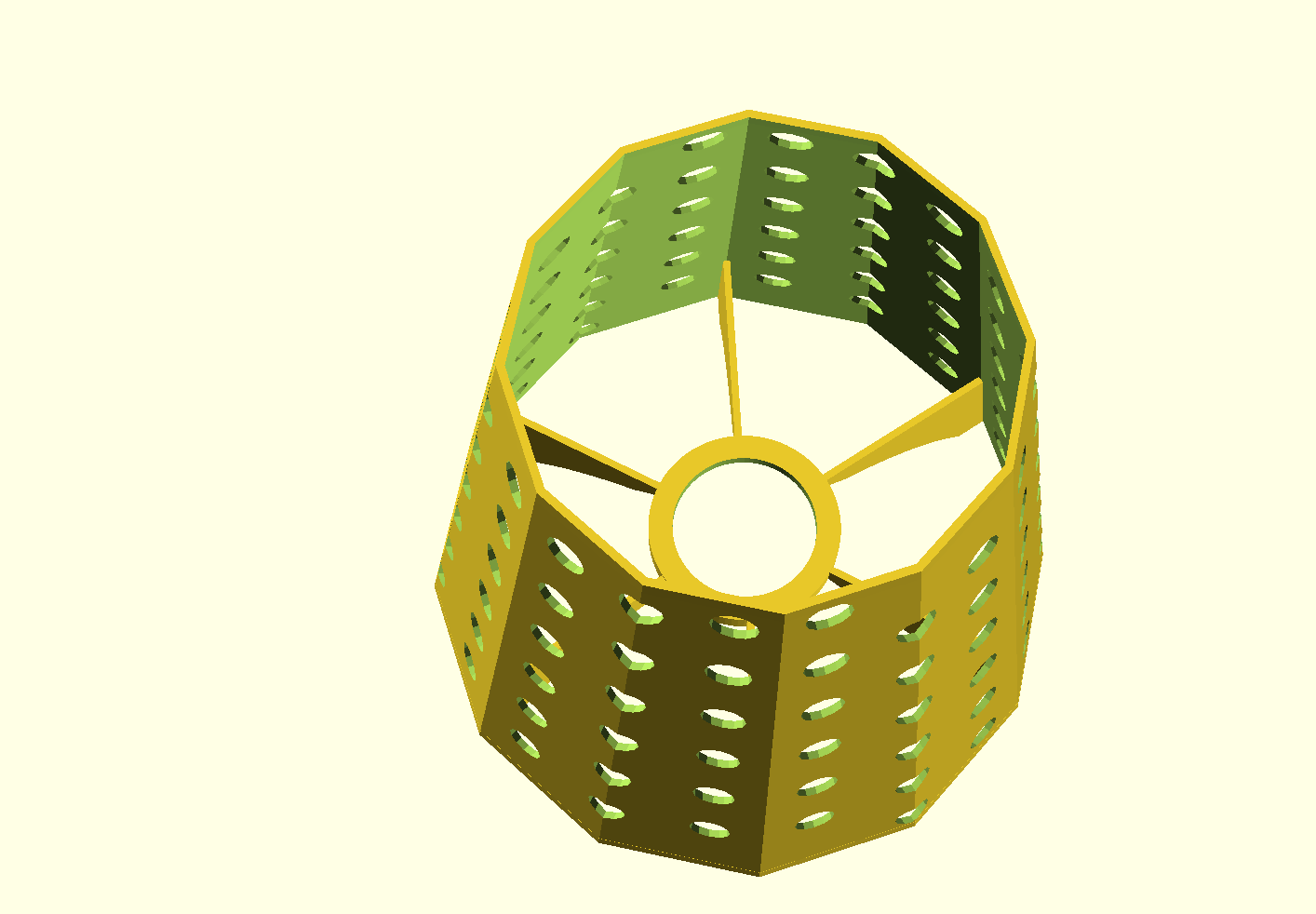

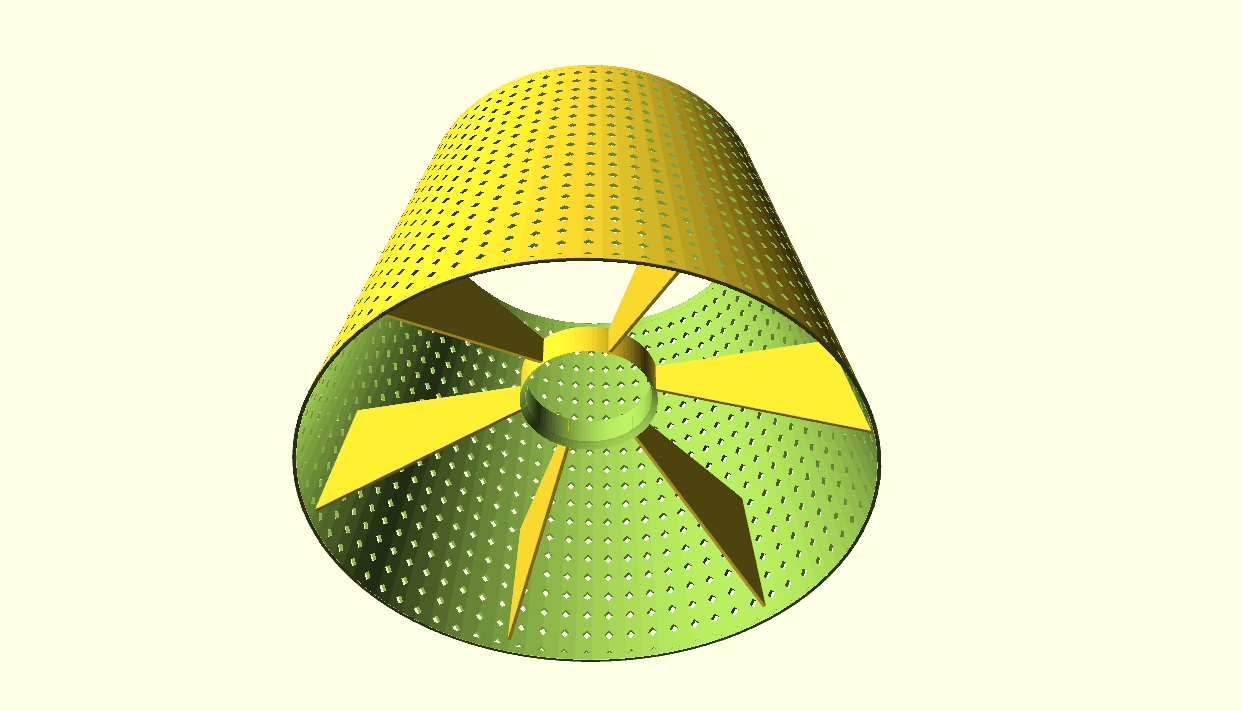

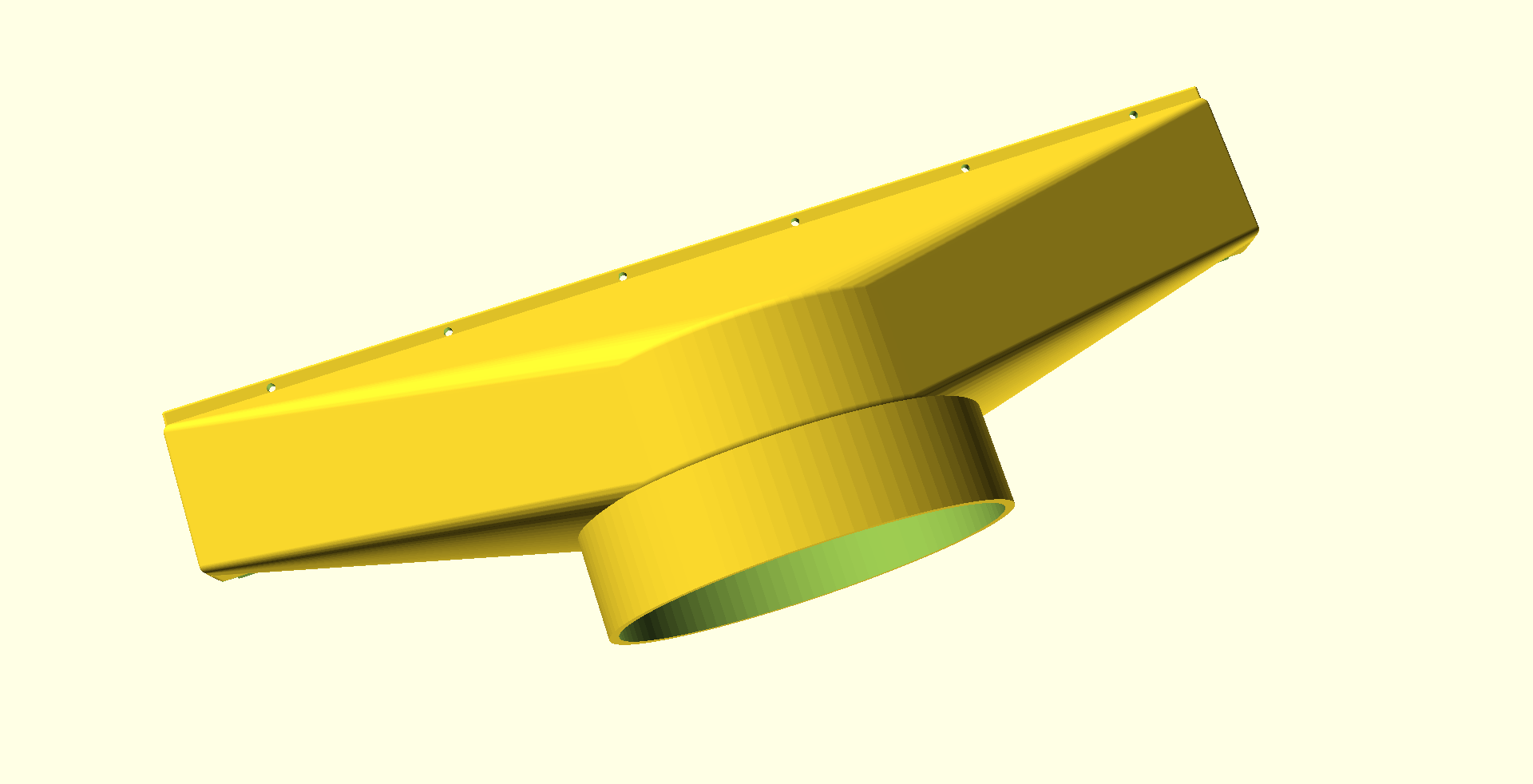

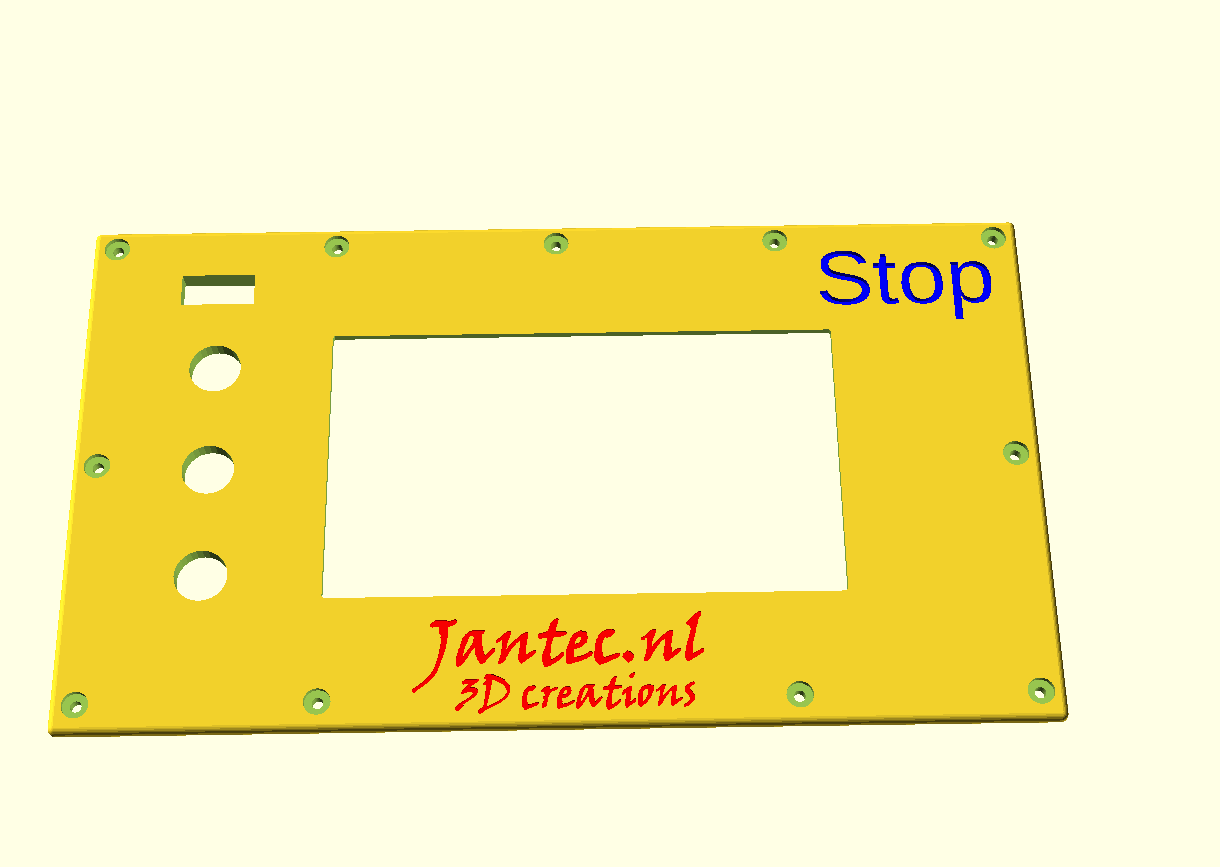

3. The last available STL for the FYSETC 7 inch DWC font panel is below:

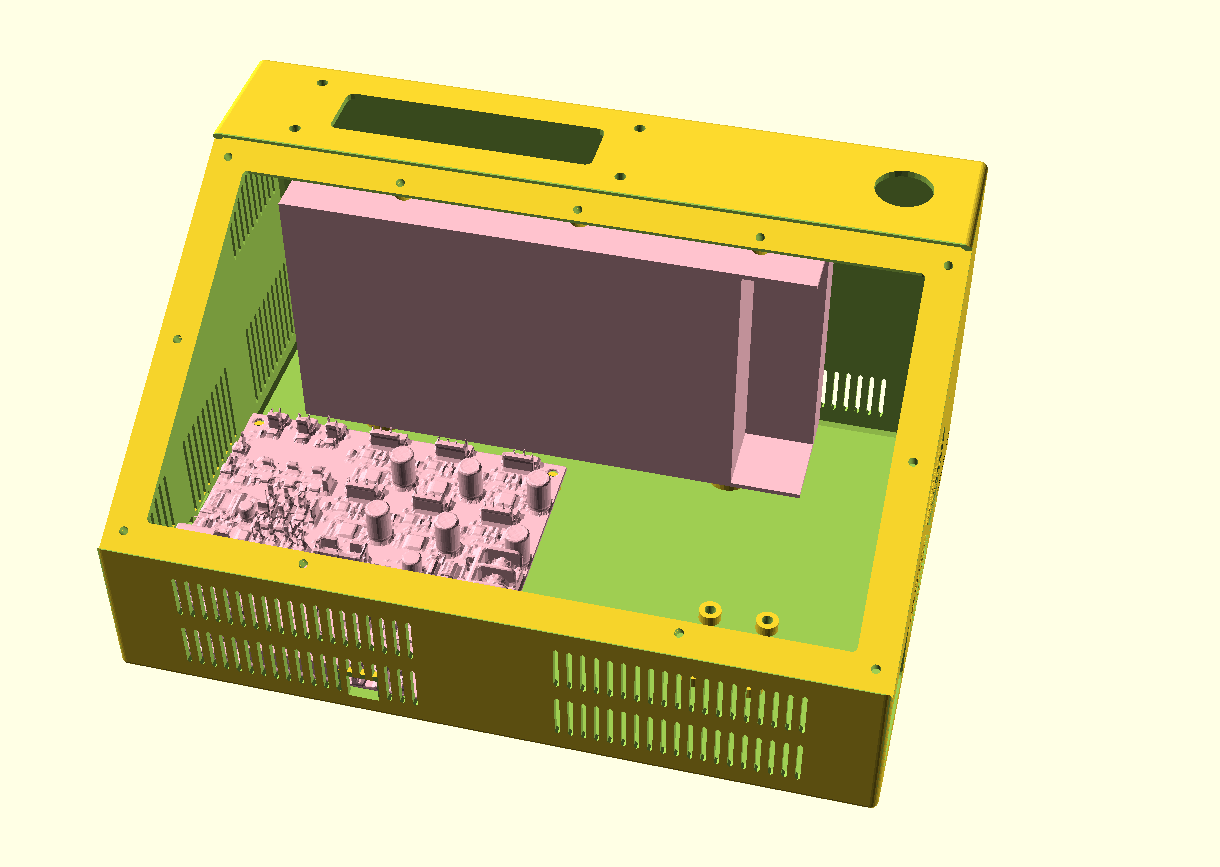

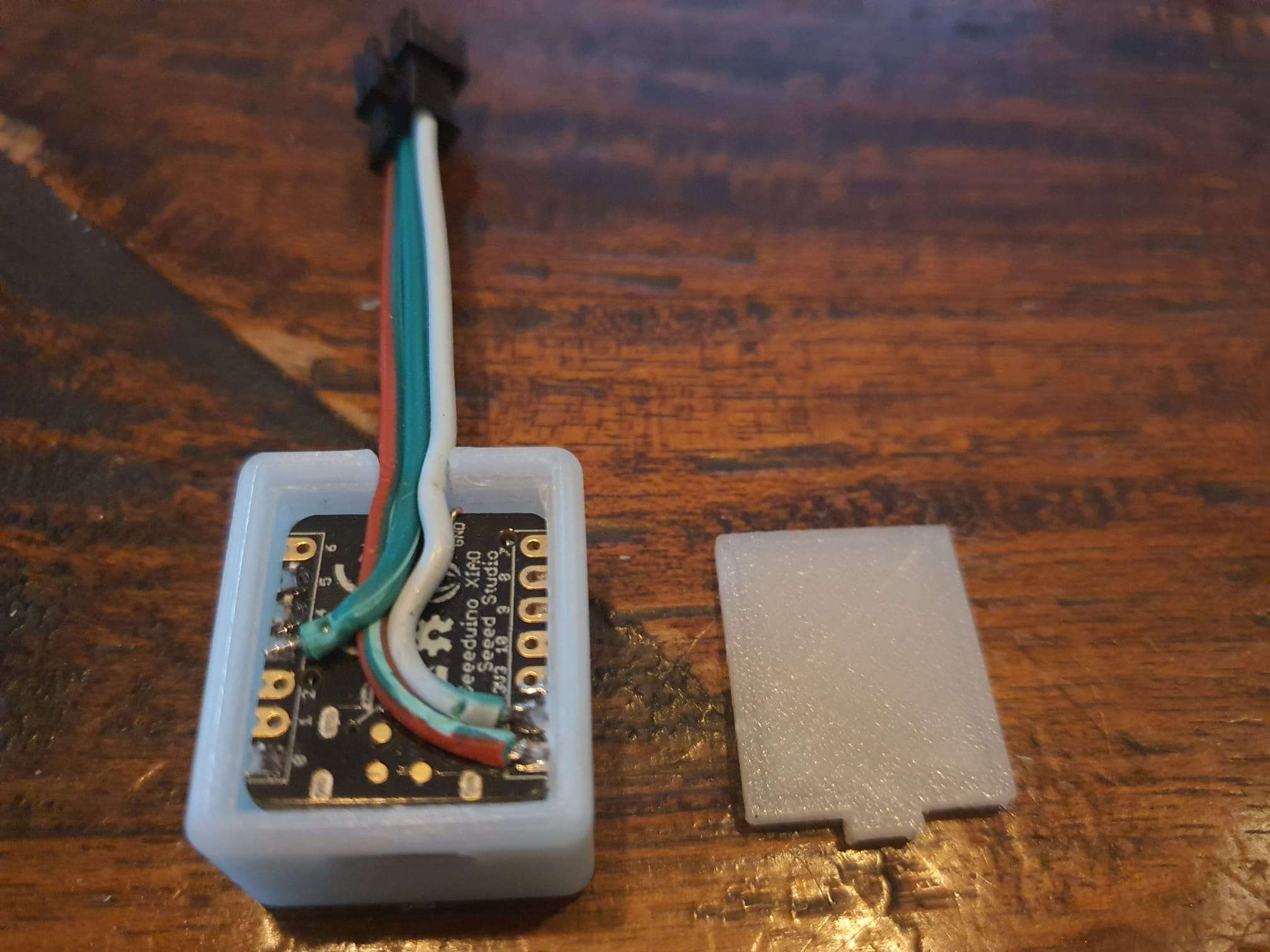

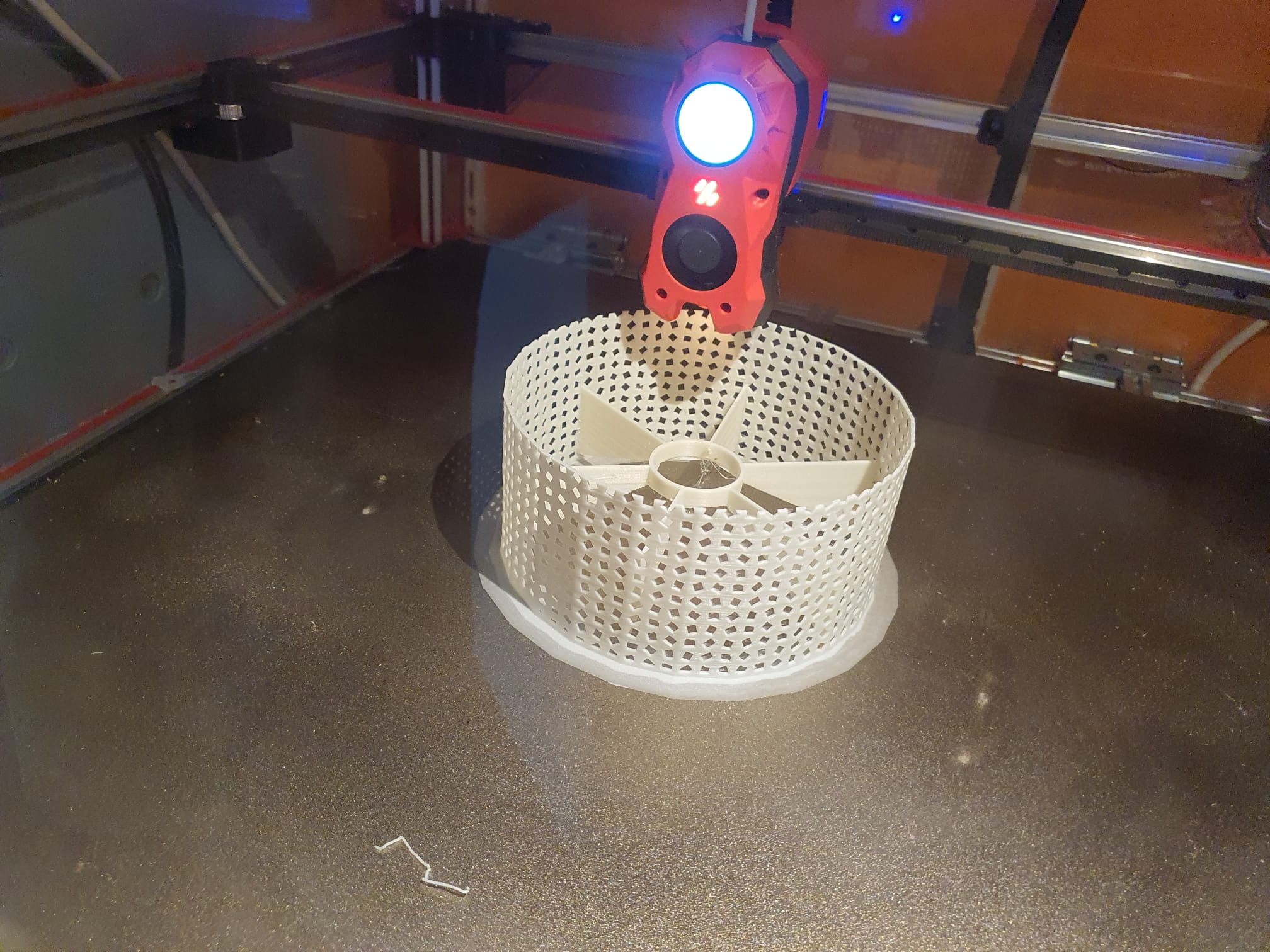

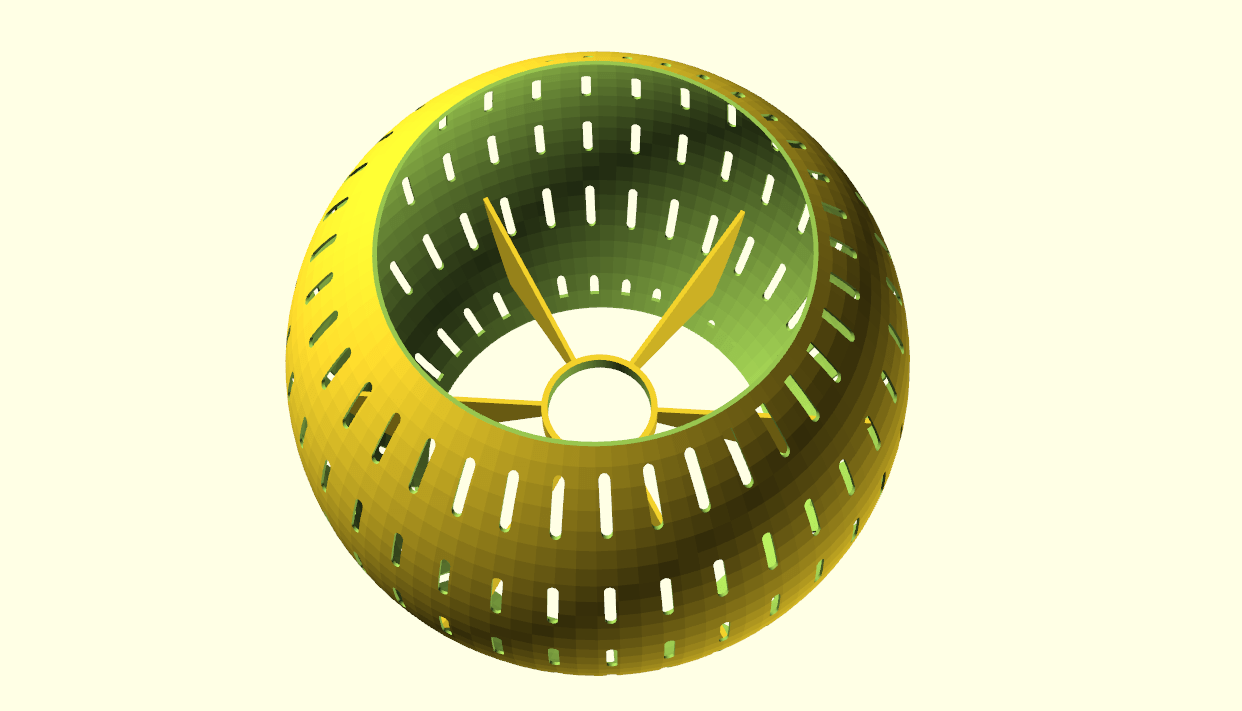

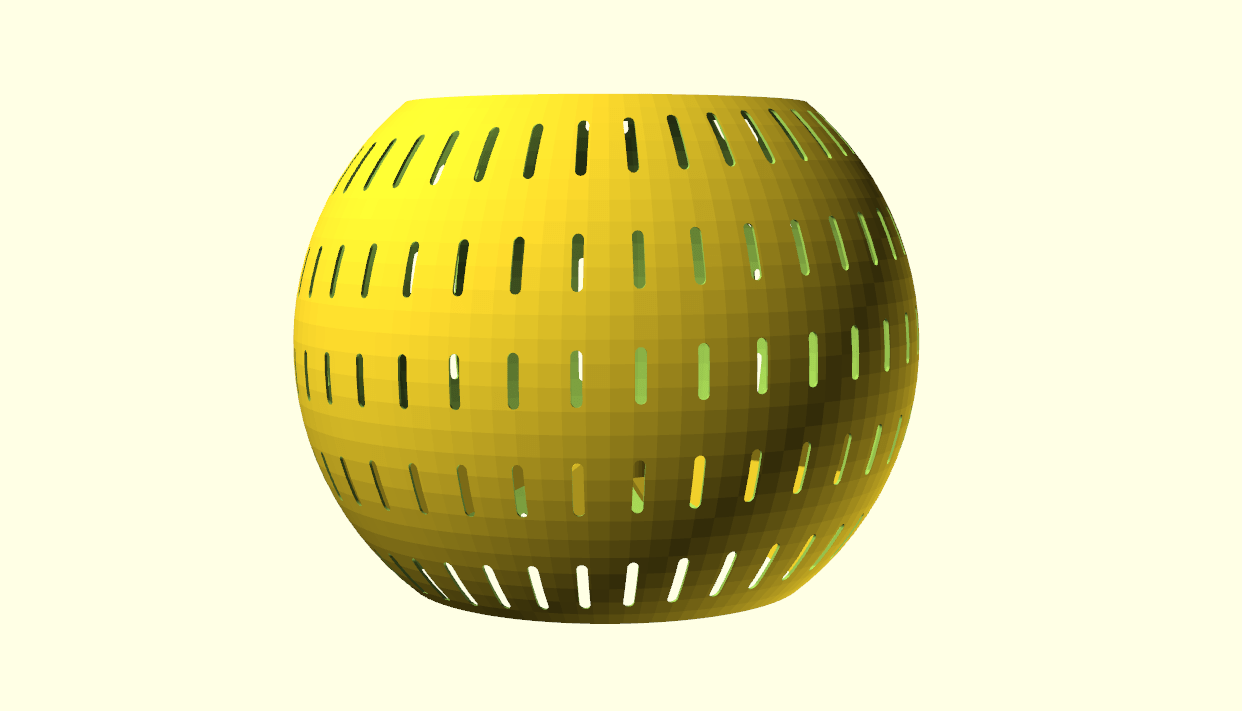

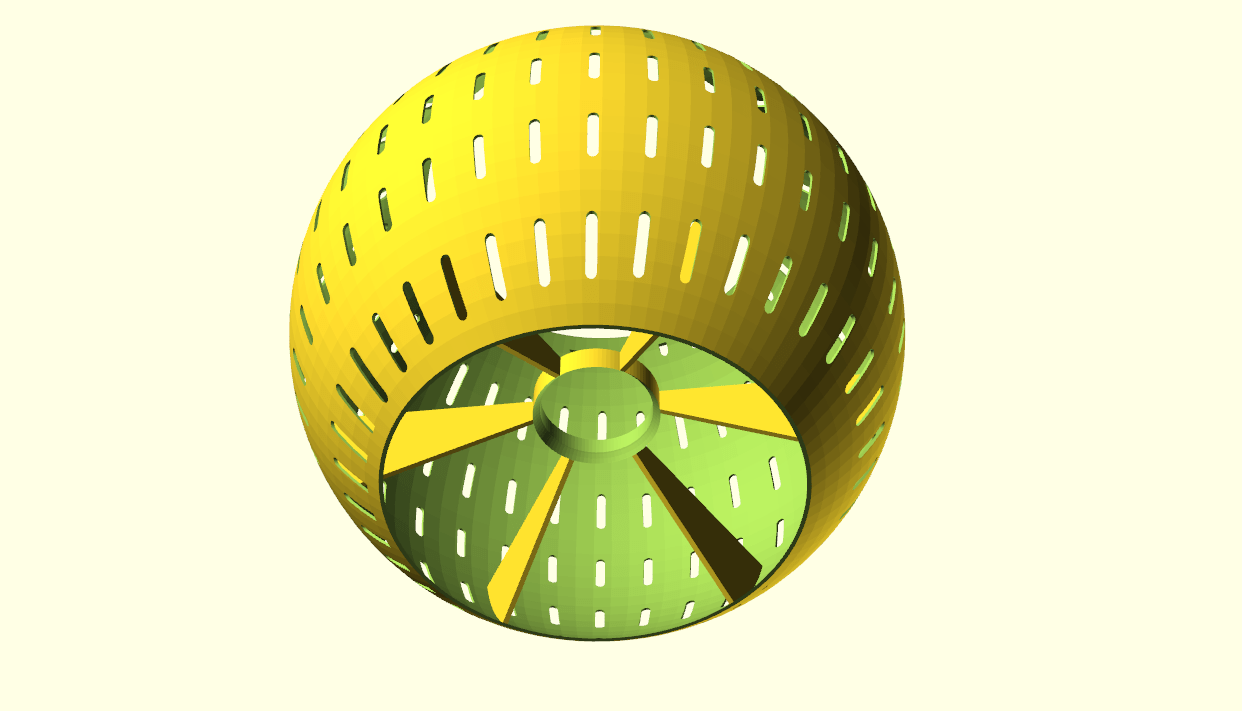

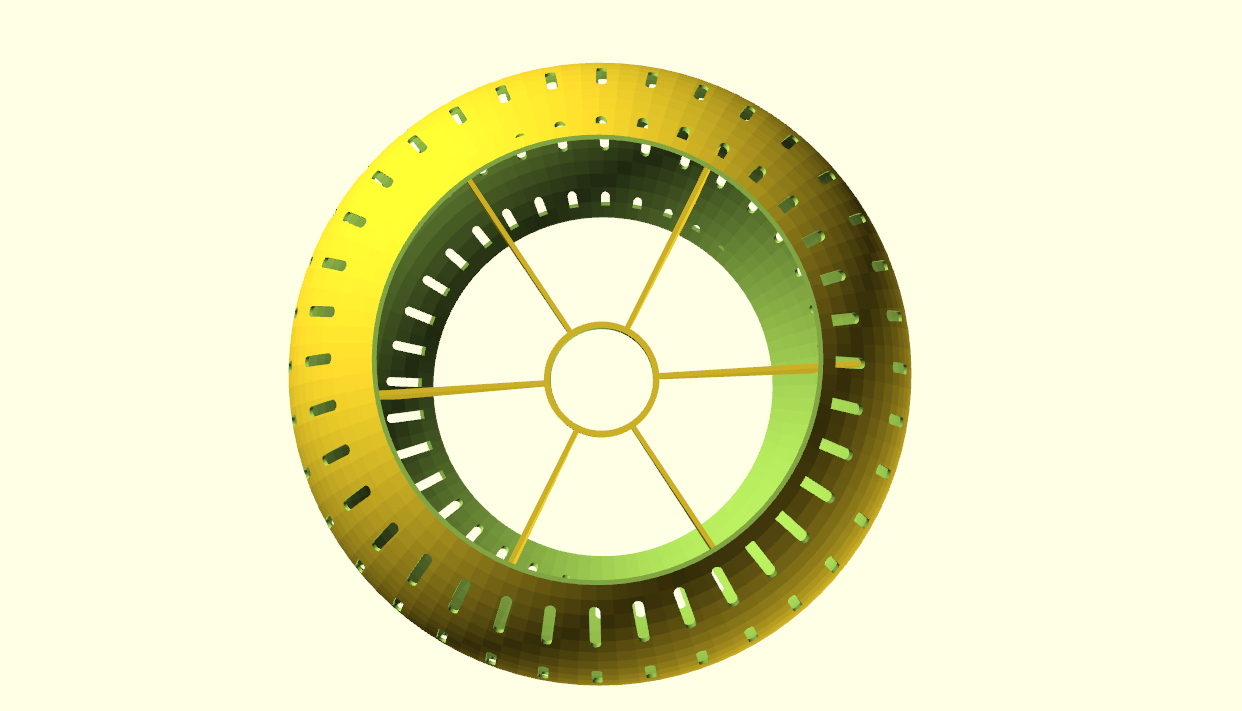

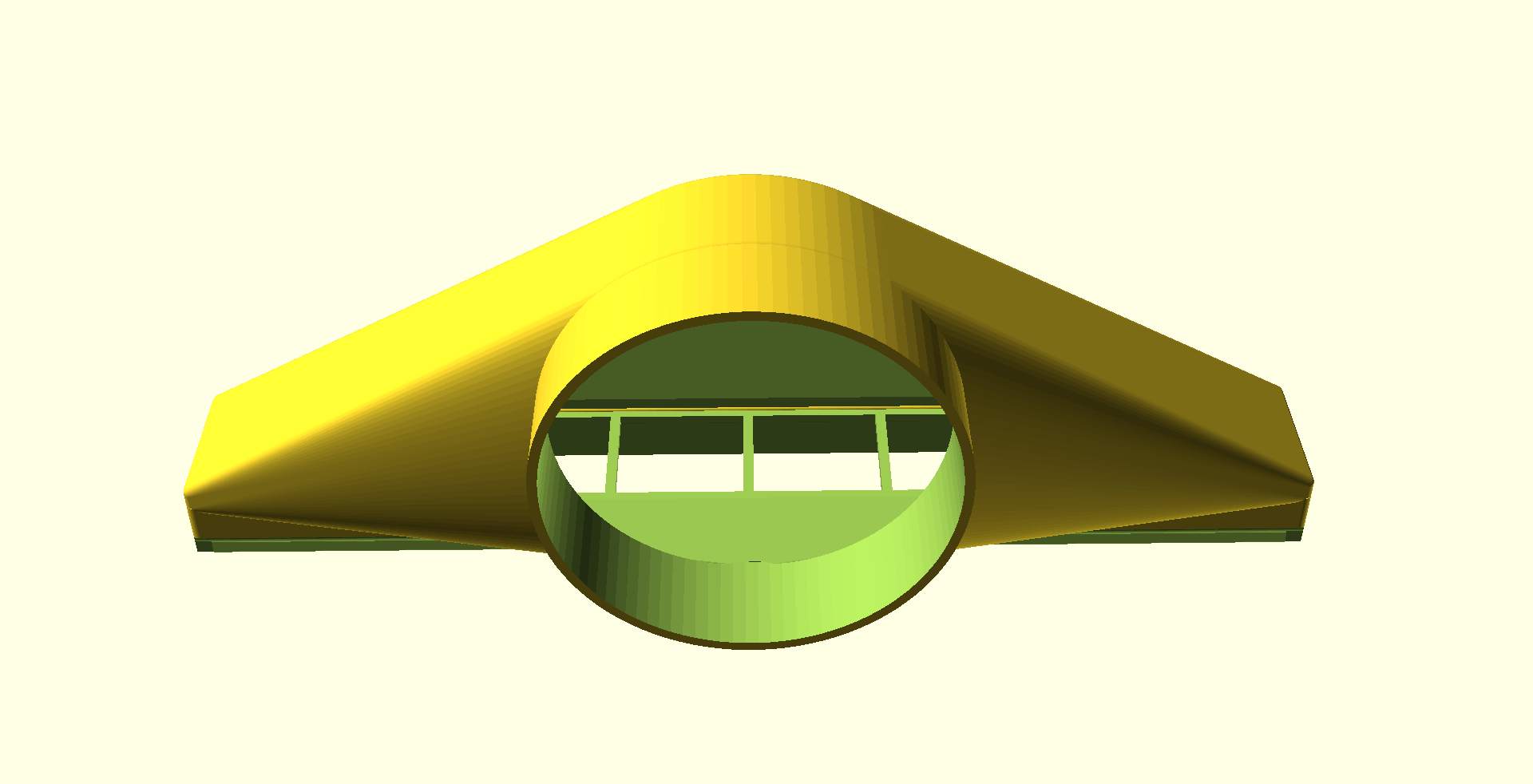

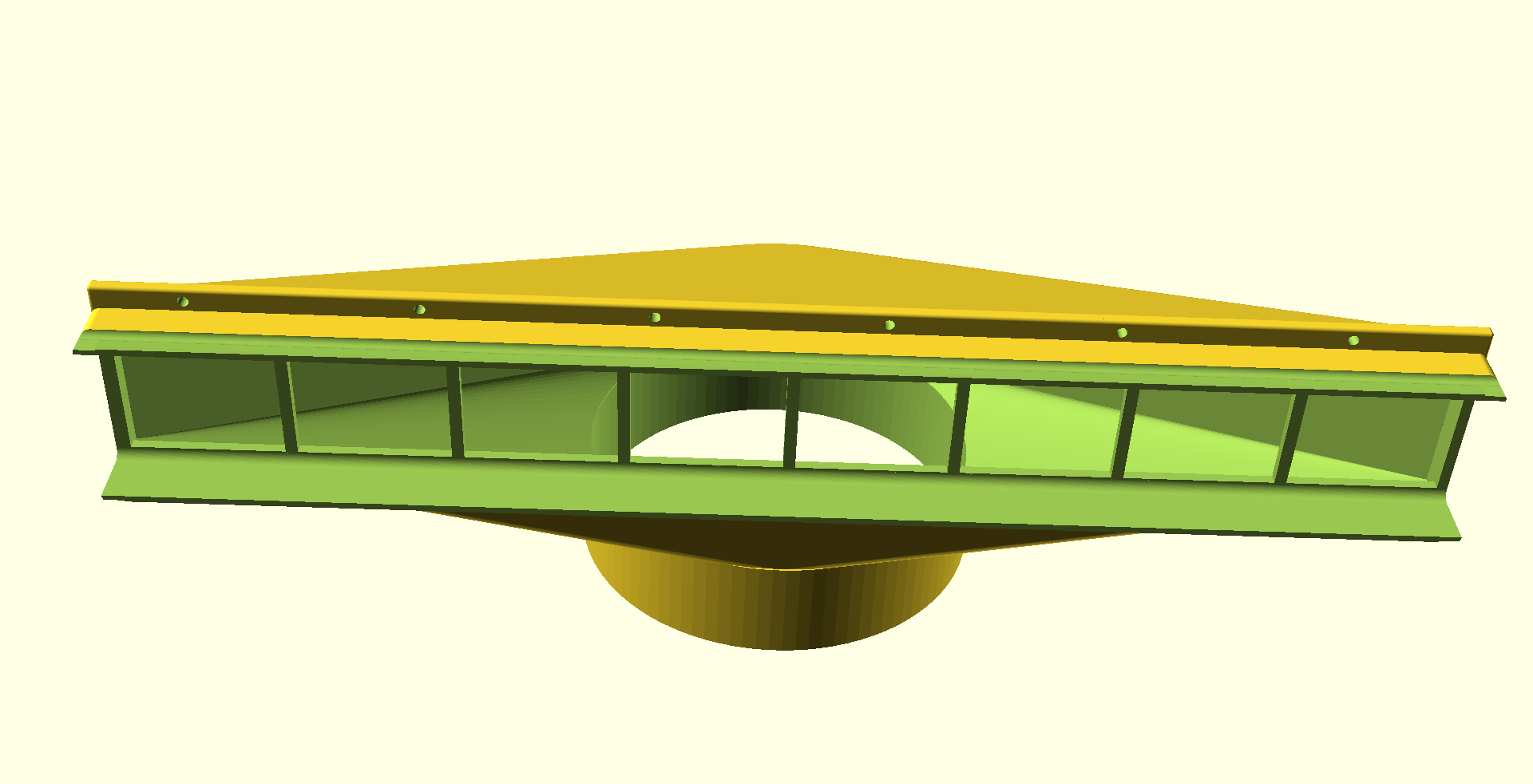

SHOWN WITH MOCKUP PARTS INSIDE:

Please donate $1 to my paypal account if you use my original designs -)