My 1970 Citroën ID20/DSuper5 ‘Oord-rebuild’ convertible is for sale because I need the space for other things I want to do.

The price for the car is Euro 37.500

Info can be obtained via phone or app at +31 611008778.

The car is in good driving condition but I do not drive it often, max 100-200 km each year for the last 10 years. I find it easier to use my daily driver car which is parked out front. The Citroën ID20 Convertible is a nice car for holidays, weddings and so on.

Although a lot of time and money has been invested in the car, it is by no means an original Citroën ID20 convertible.

The car is nice to drive during summers with the hood down or up. It is not a car that you want to drive in wet conditions, at least we never do.

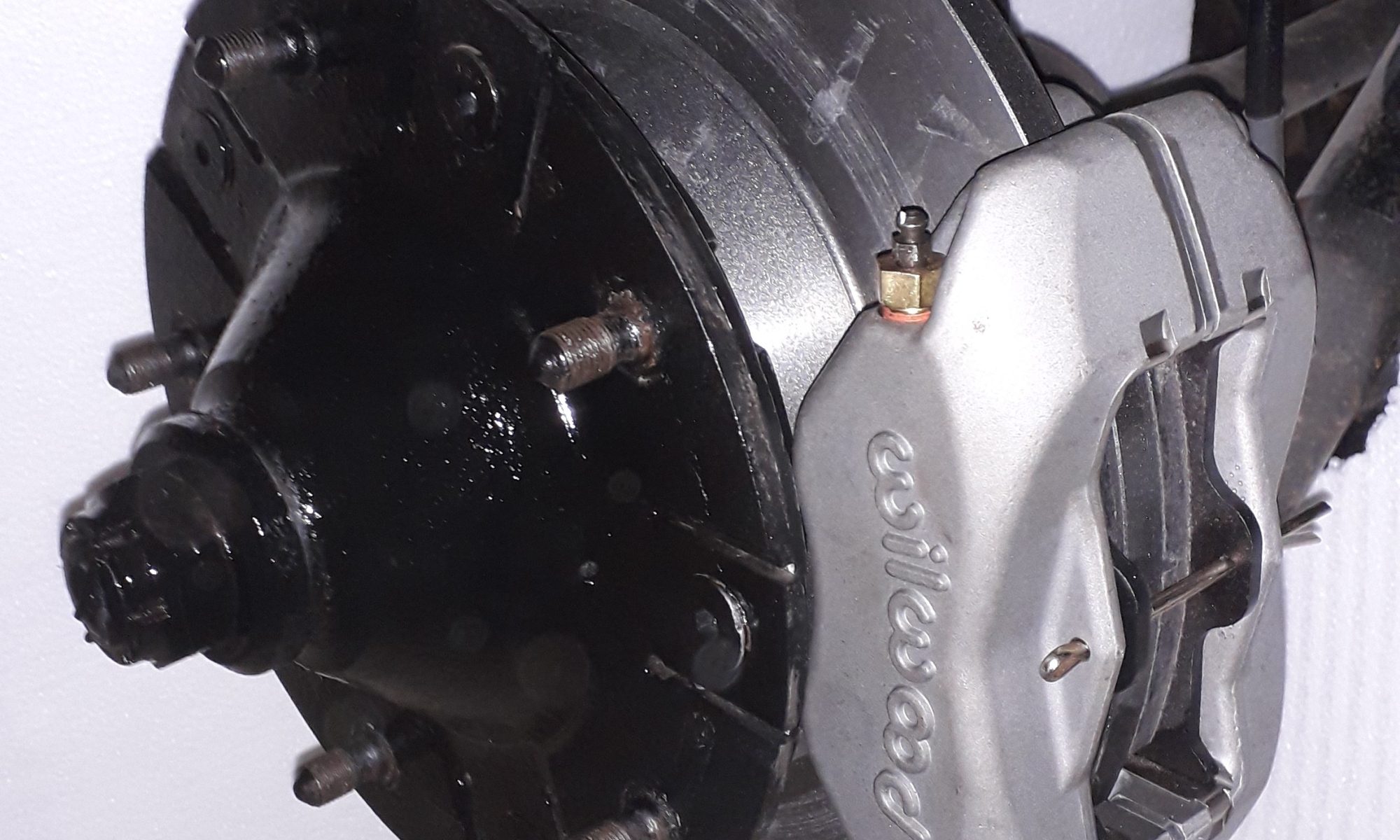

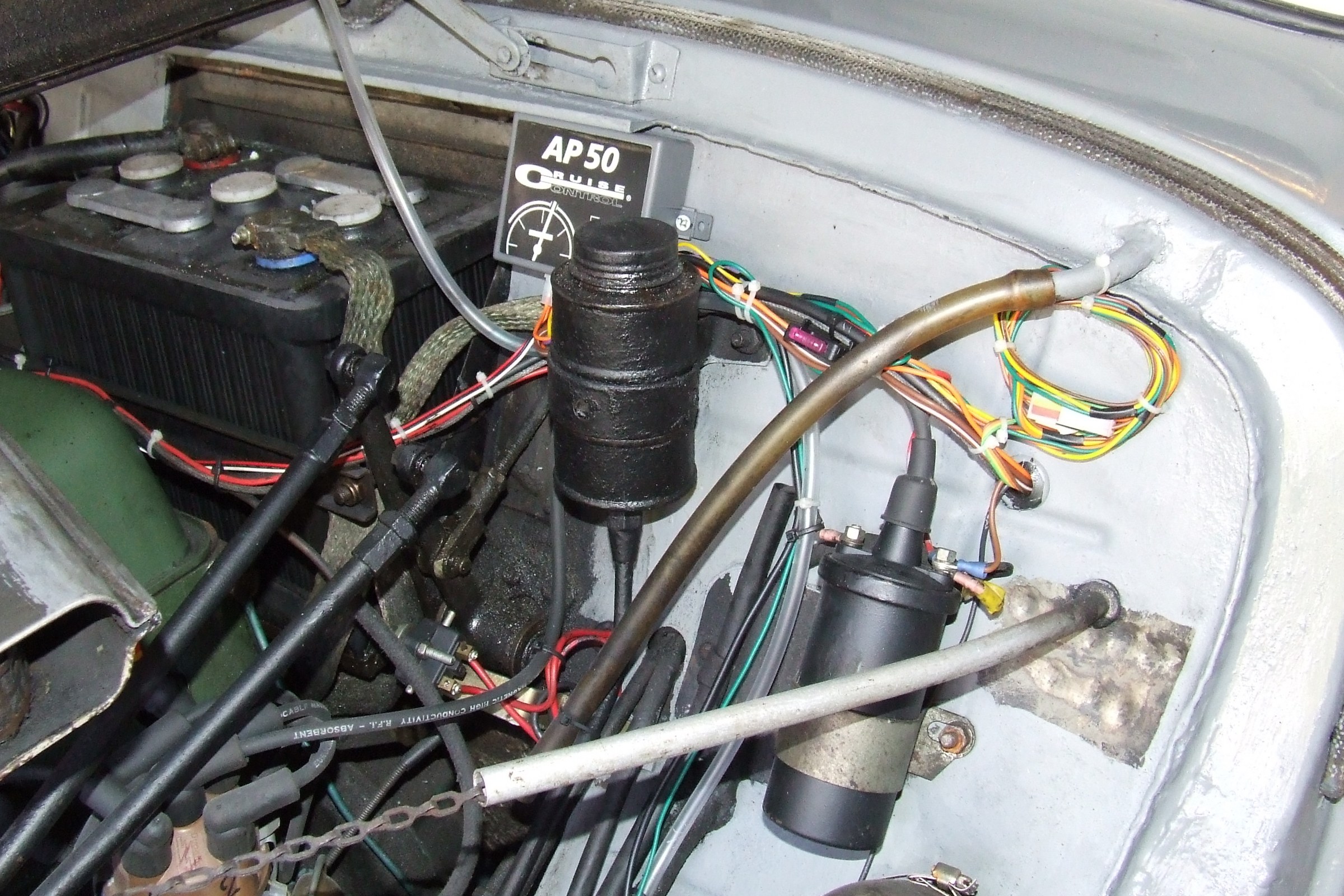

The car can very well be used in normal traffic conditions, including driving highways due to a.o. the relatively strong engine, power steering, power brakes, 5-speed gearbox and due to the electronic cruise control system.

The car runs well on gas and/or LPG (GPL).

The added pictures are taken on 10-2024 (outside) and 06-2025 (in our Amsterdam garage): the car is always parked inside.

PS: In the photo’s below, my favourite (Volvo C70 cabrio) front chairs were mounted in the car, but I have taken these out due to the sale of the car and remounted the original newly upholstered ID20 chairs. Photo’s with the original leather ID20 chairs are shown further down in this post.

The original ID20 chairs are newly upholstered:

I bought the car as berline in 2006 and drove it as our holiday car between 2006 and 2012. The basic rebuild to cabrio in 2016/2017 was done by the (then) coachbuilder company Oord DS cabrio, in the Netherlands (Zwaag, near Herenveen). Unfortunately, this company went out of business in 2020.

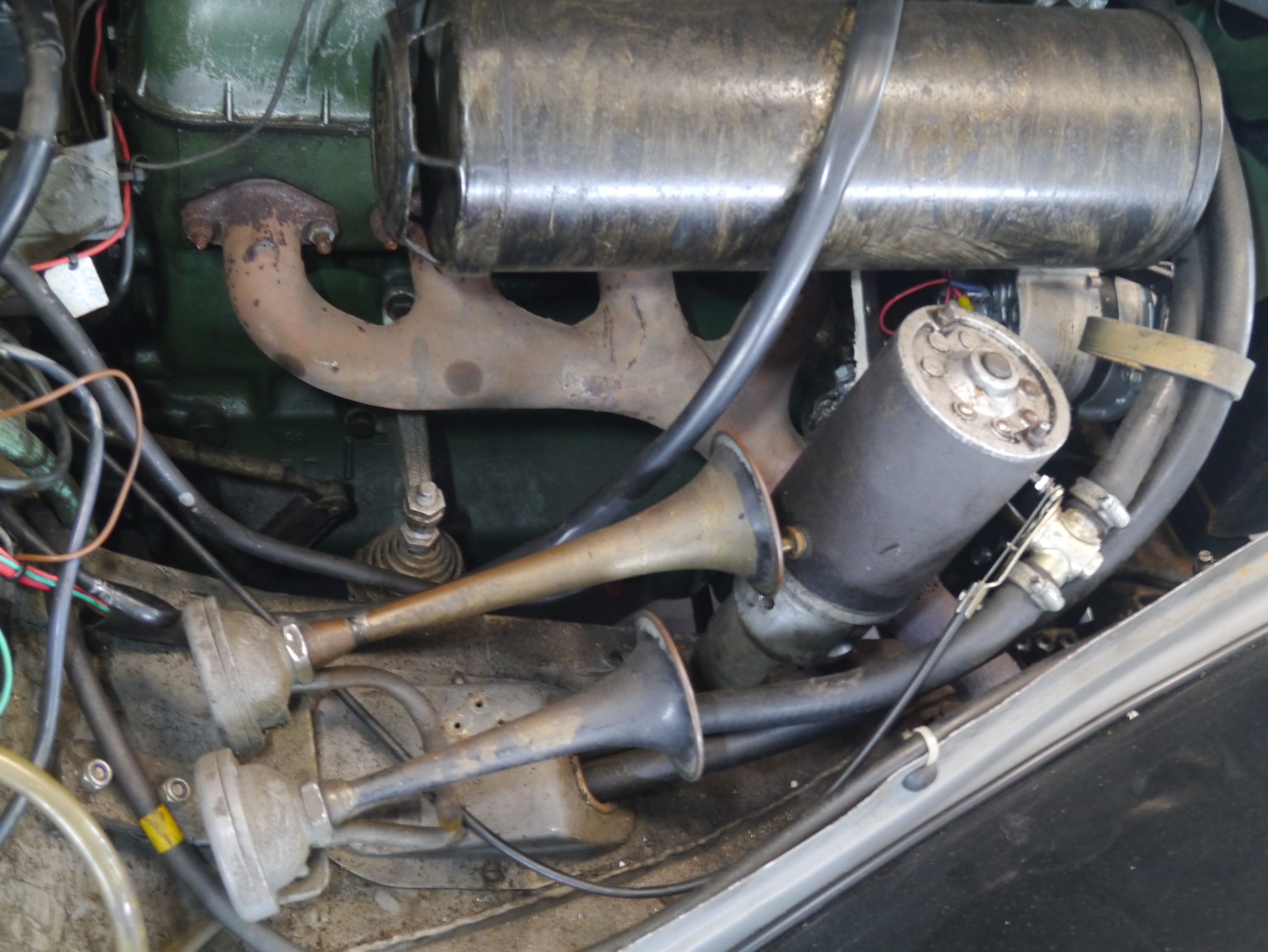

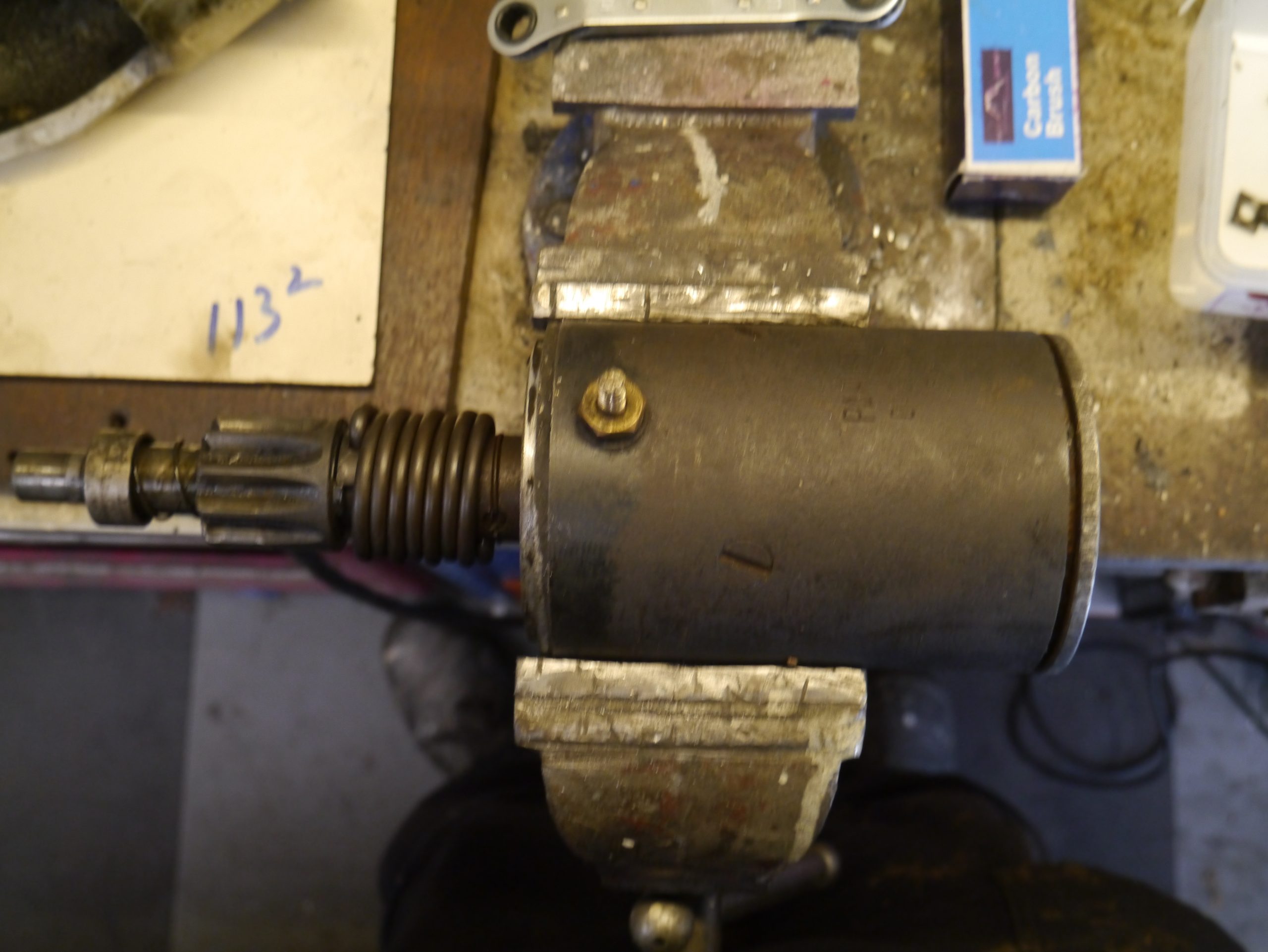

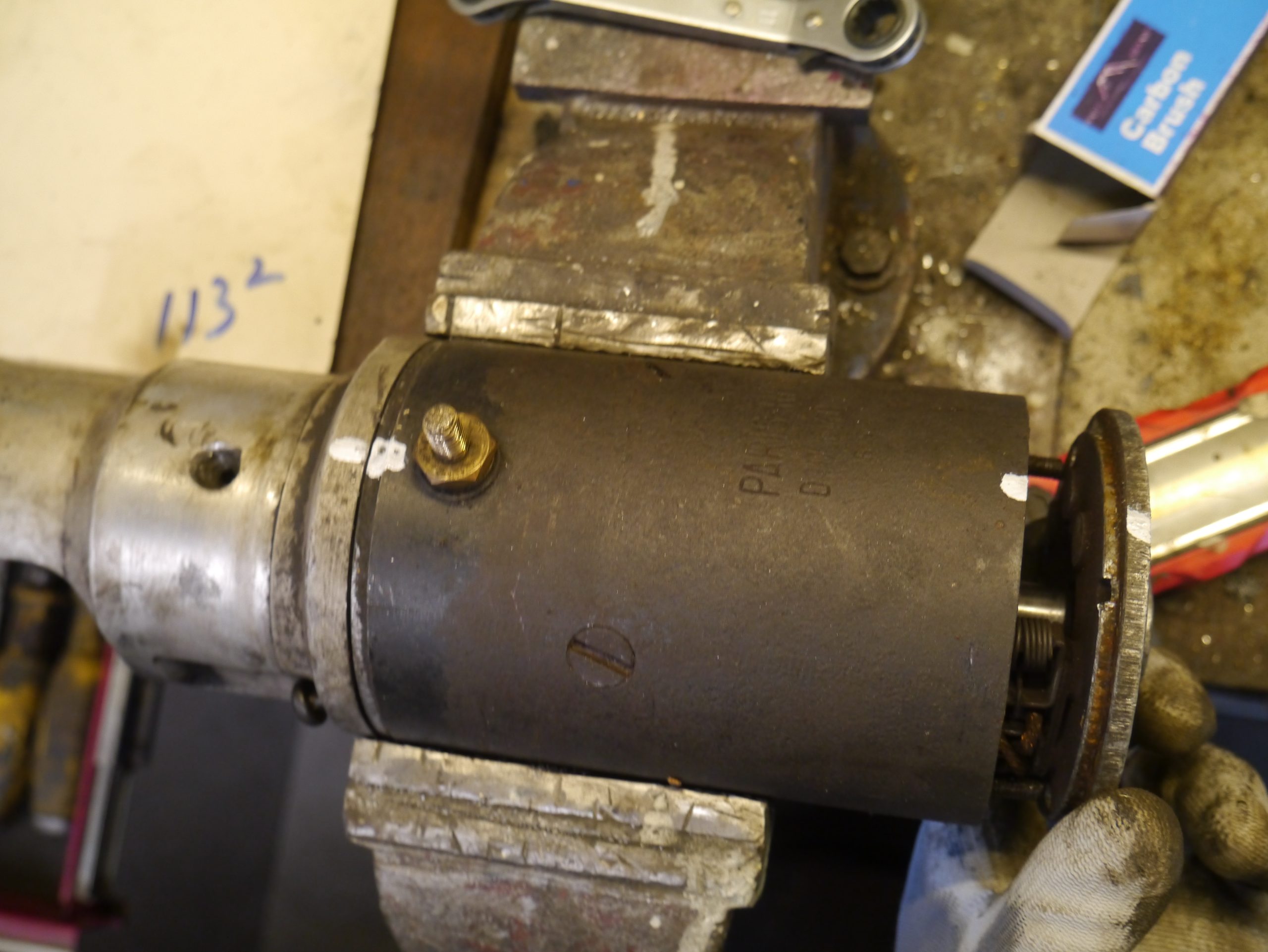

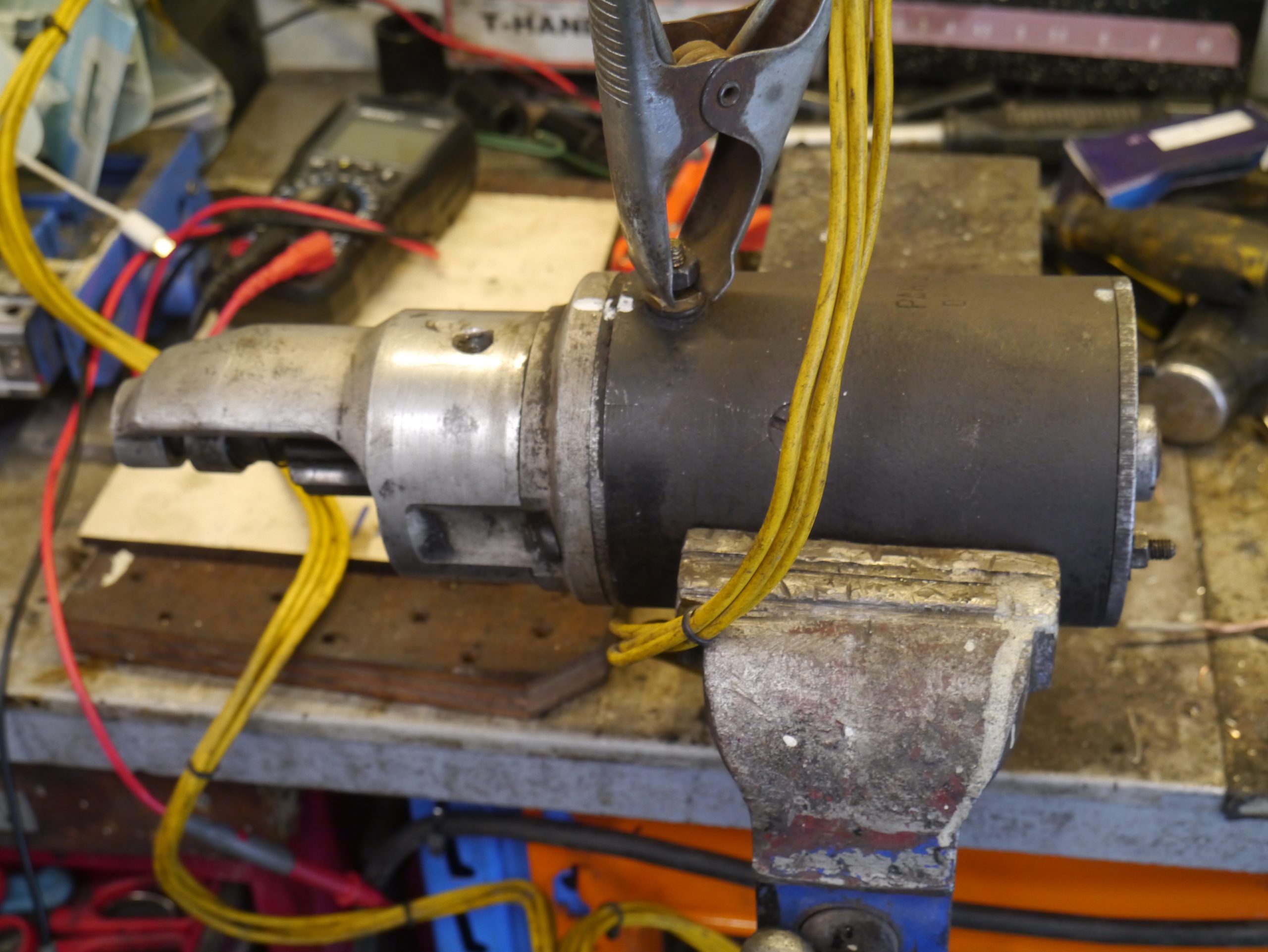

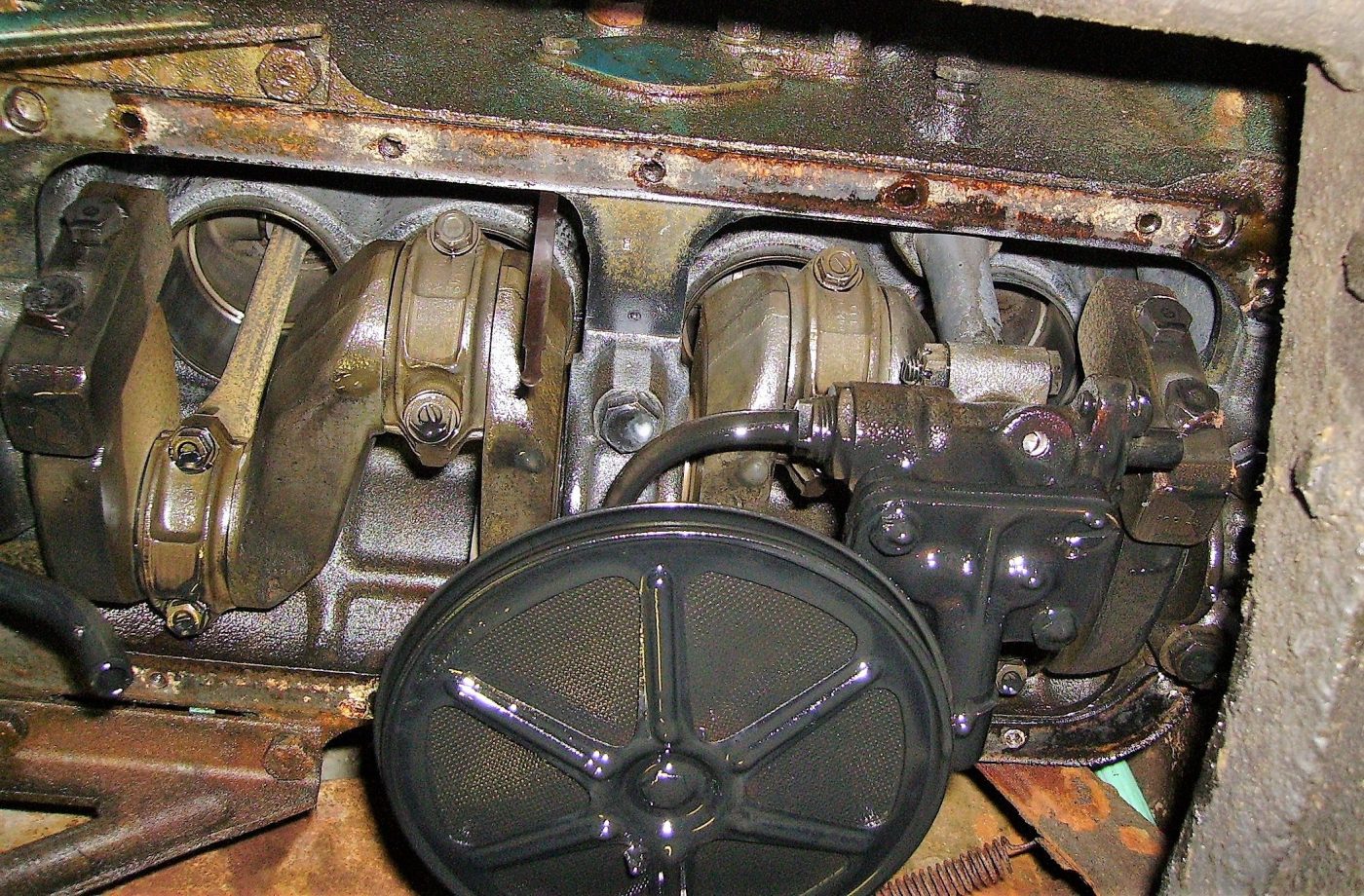

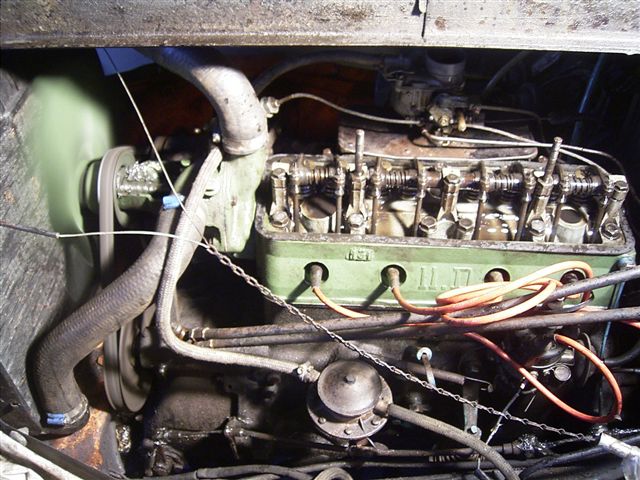

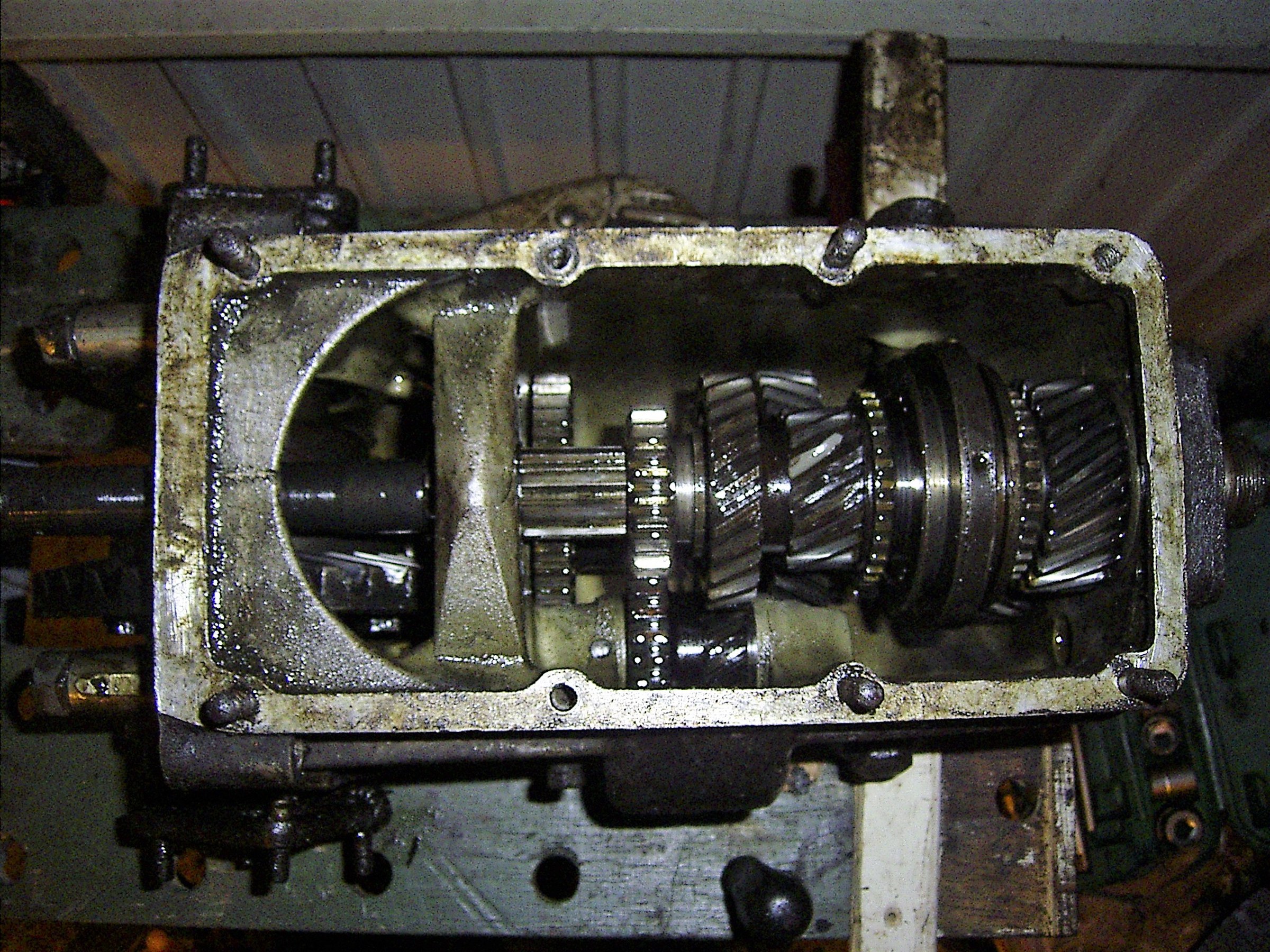

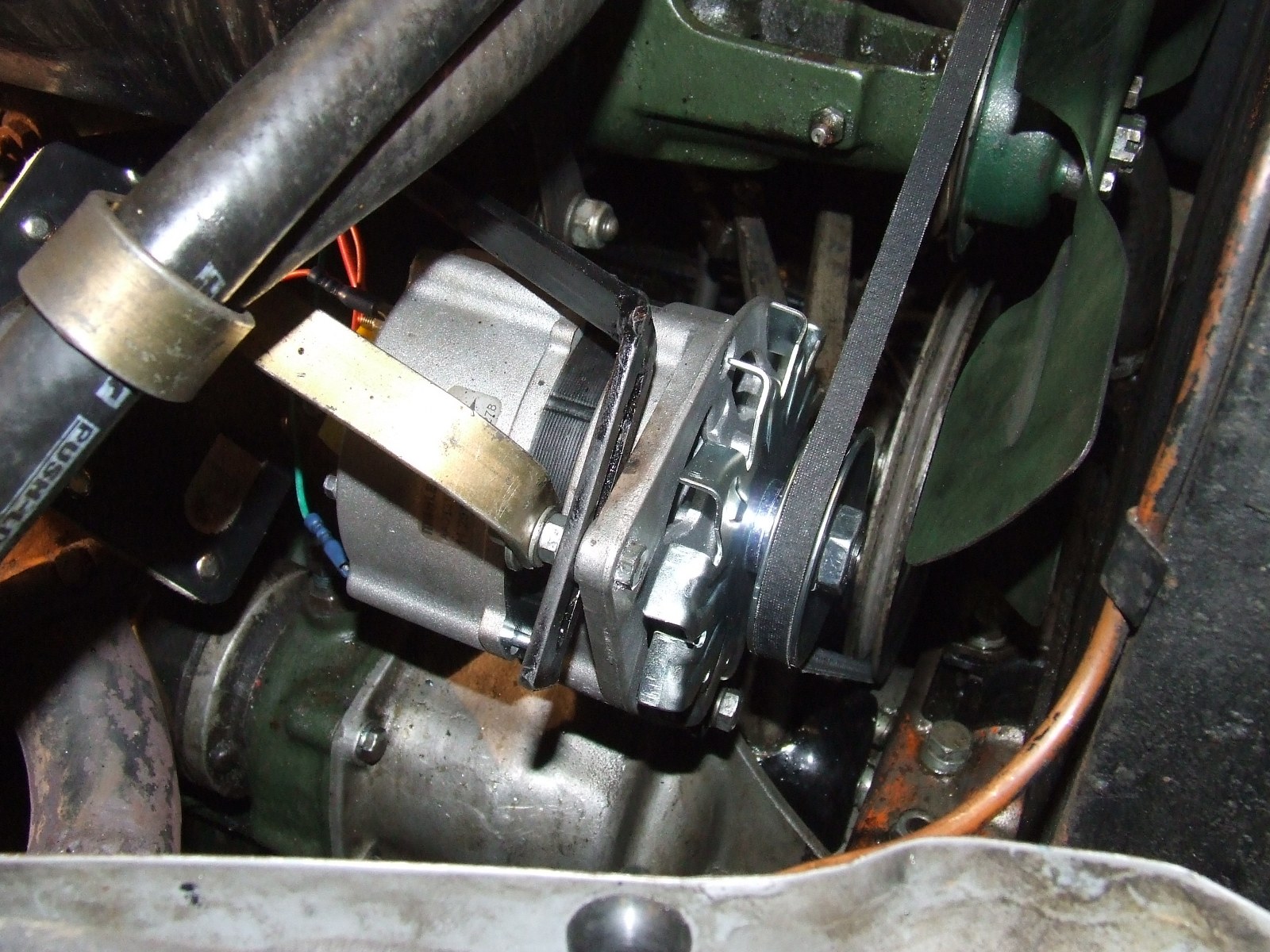

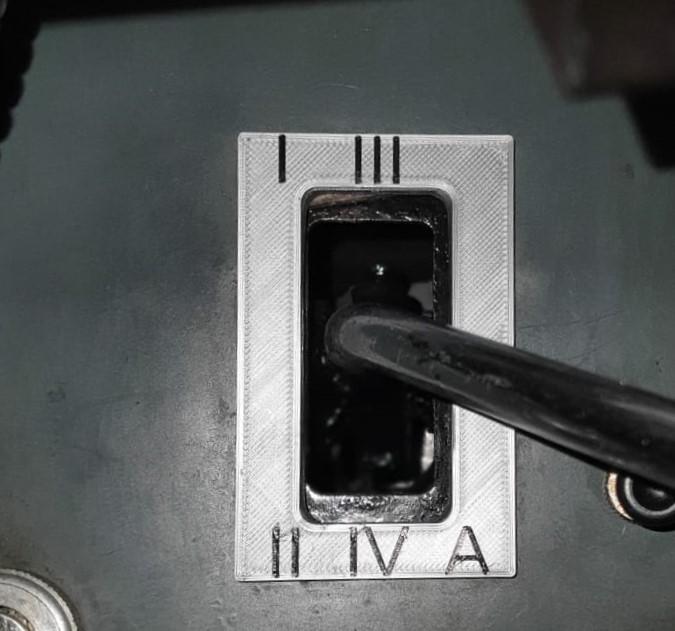

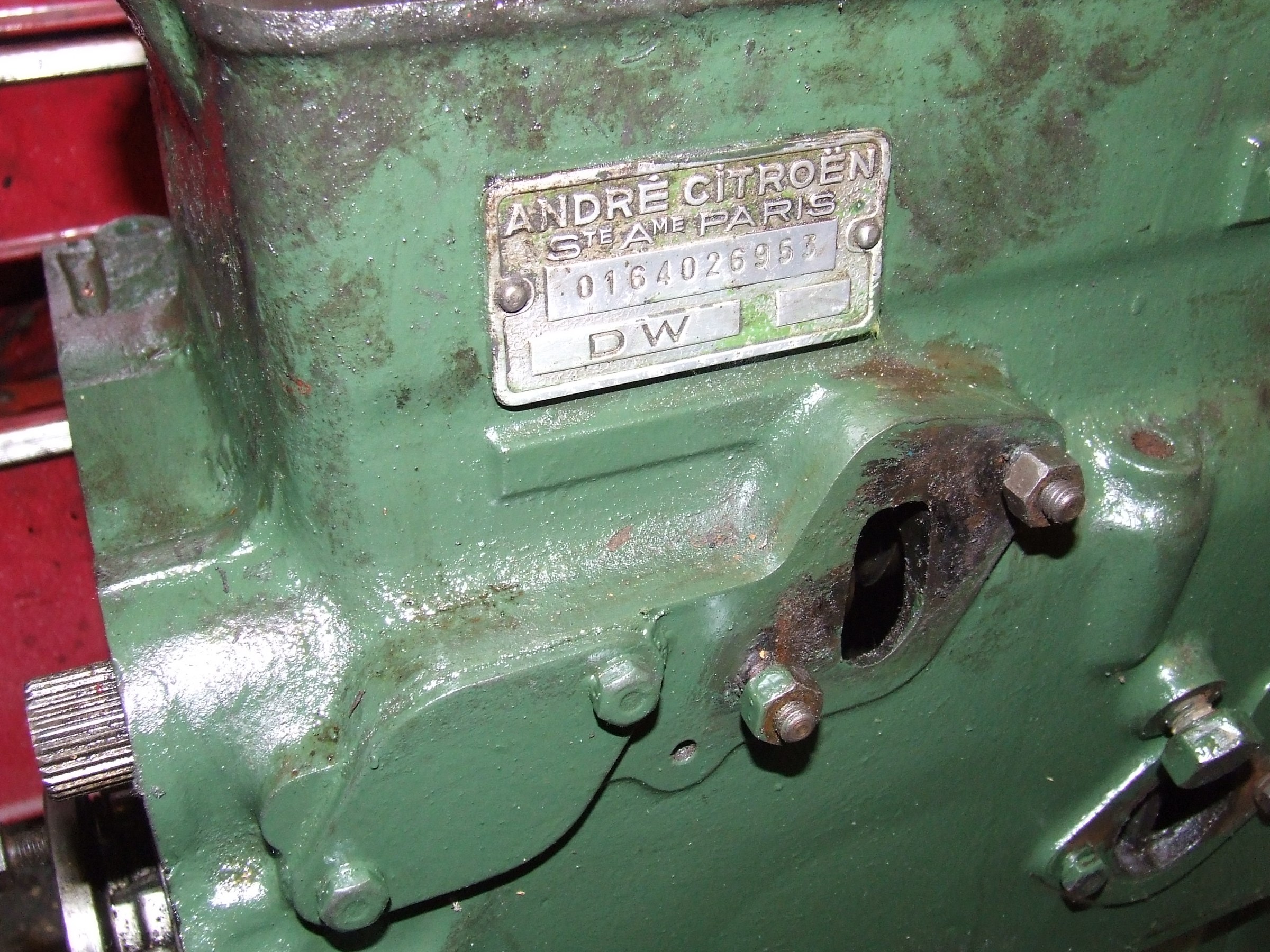

The car is equipped with its original 2.2 liter DX2 engine and the belonging 5-speed ‘long’ gearbox.

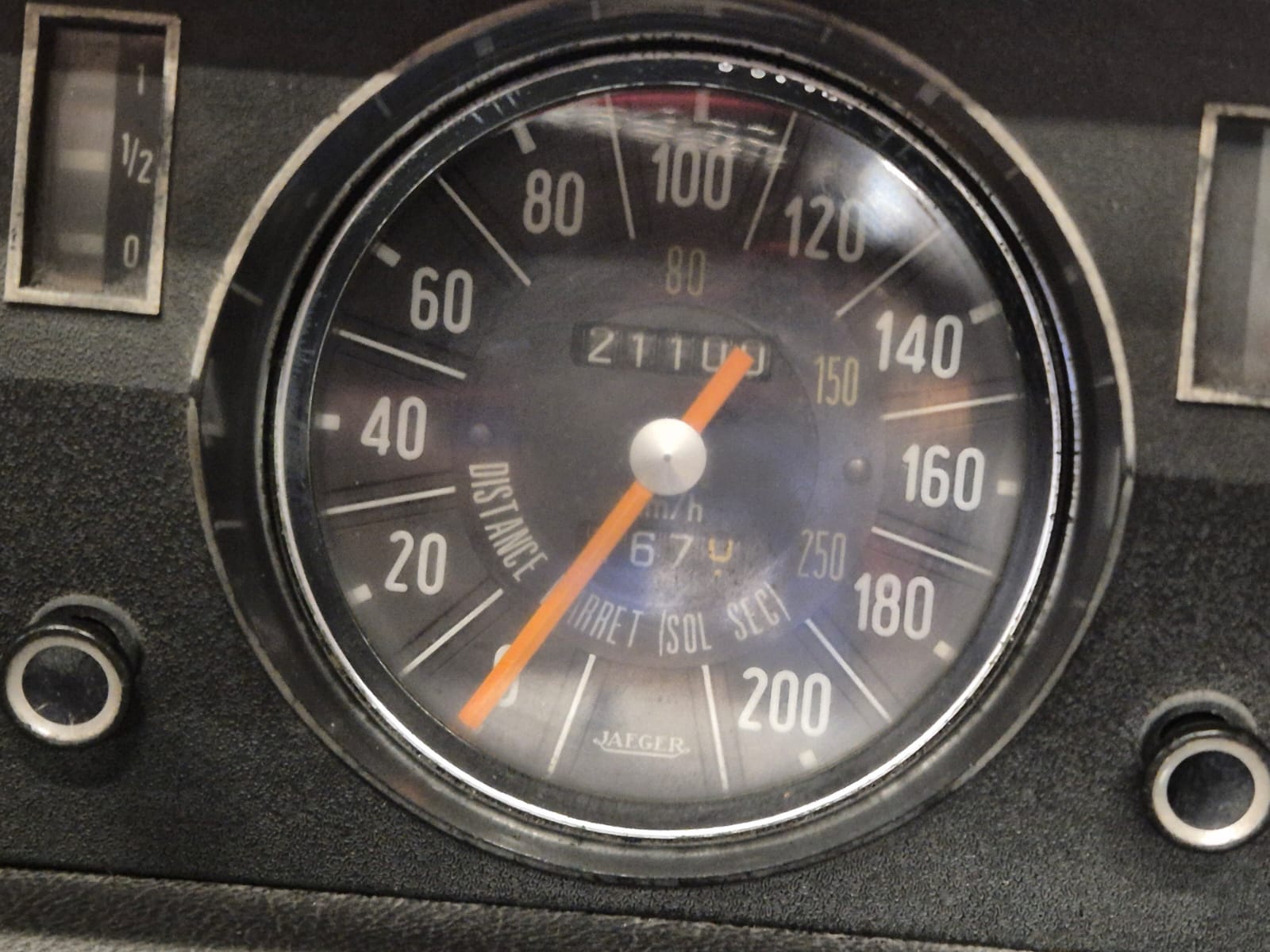

Both the enine and the 5-speed gearbox are OK to drive, and have never been overhauled. The mileage (in kilometers) is difficult to see, due to the fact that these cars’ kilometer counter rewinds at 100.000 kilometers It is likely that the car has done about 121.000 kilometers, given the state it was in when I bought it in 2006. But it might just as well have driven 321.000 kilometers. We just don/t know this for sure.

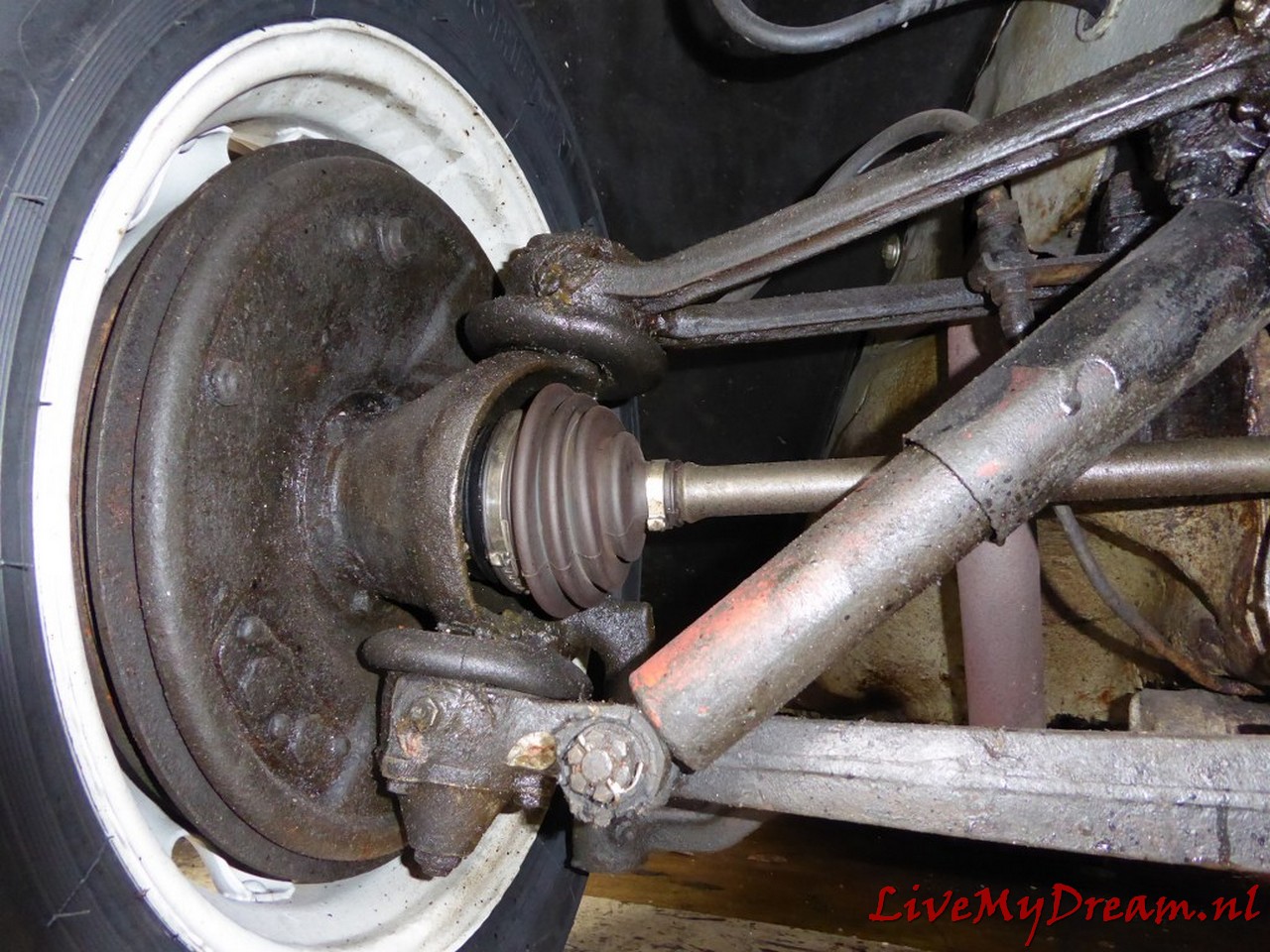

However, due to good maintenance, care and little using the car the last 30 years, the car is in good drivable state. Plus, during the rebuilding to cabrio by the ‘Oord’ coach bulding company, a lot of strengthening has been done to the car’s body, as regulations require this. The car comes with a proper Dutch Citroën ID cabrio title.

The car has always been insured and the last 10 years we drive it usually 1-4 times a year, max 100- 200 km/year

After the basic rebuild to cabrio, we got the updated car’s title as cabrio and we then have worked at the car during summers. We put on a new boot, a new roof, had the old chairs upholstered with new leather, et cetera.

Then, finally we had the car stripped and repainted. We used NOS handlebars inside, outside, new lights, stretched rear bumper, and so on.

Finally, in 2024 we had the car’s interior upholstered.

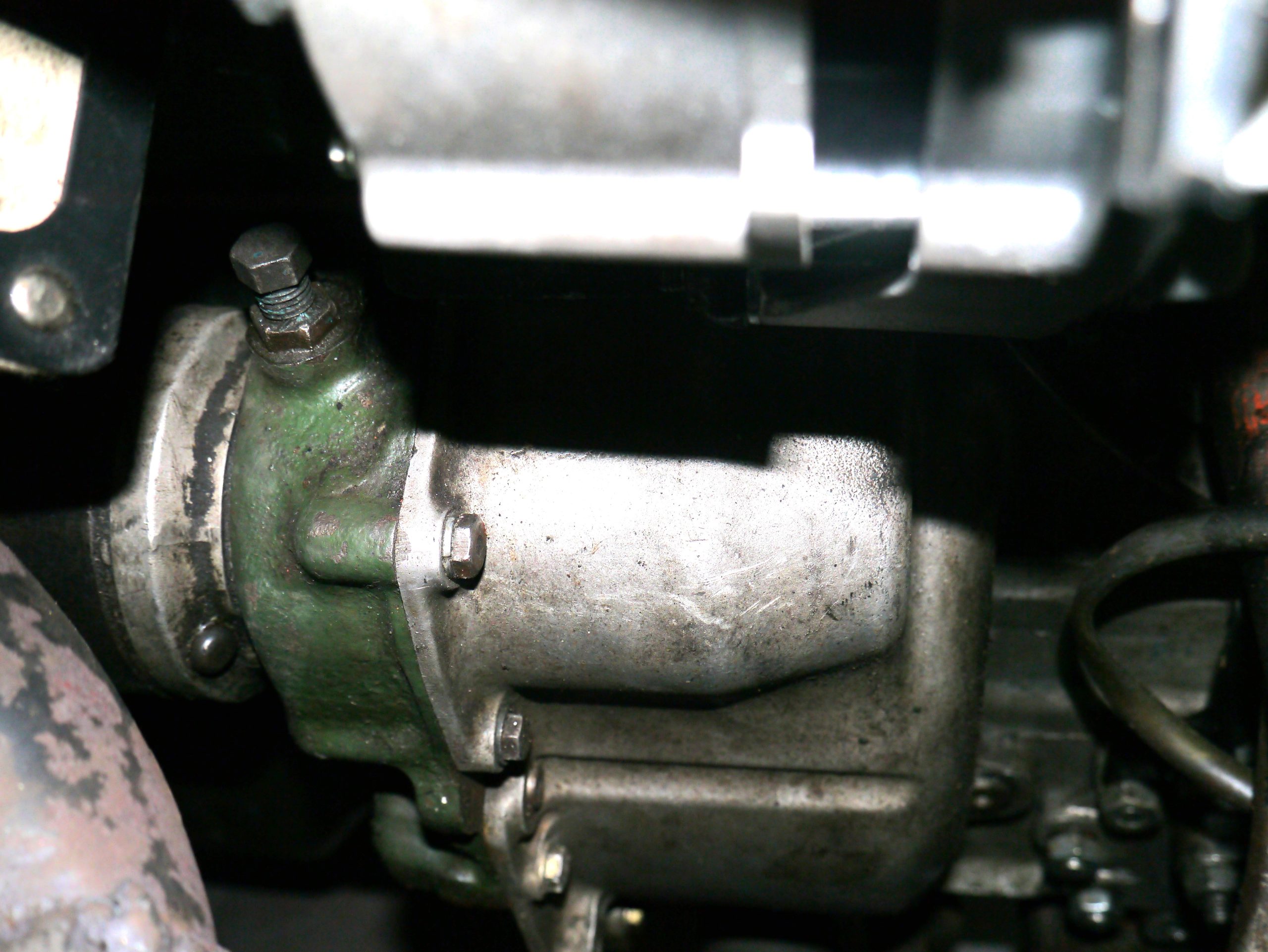

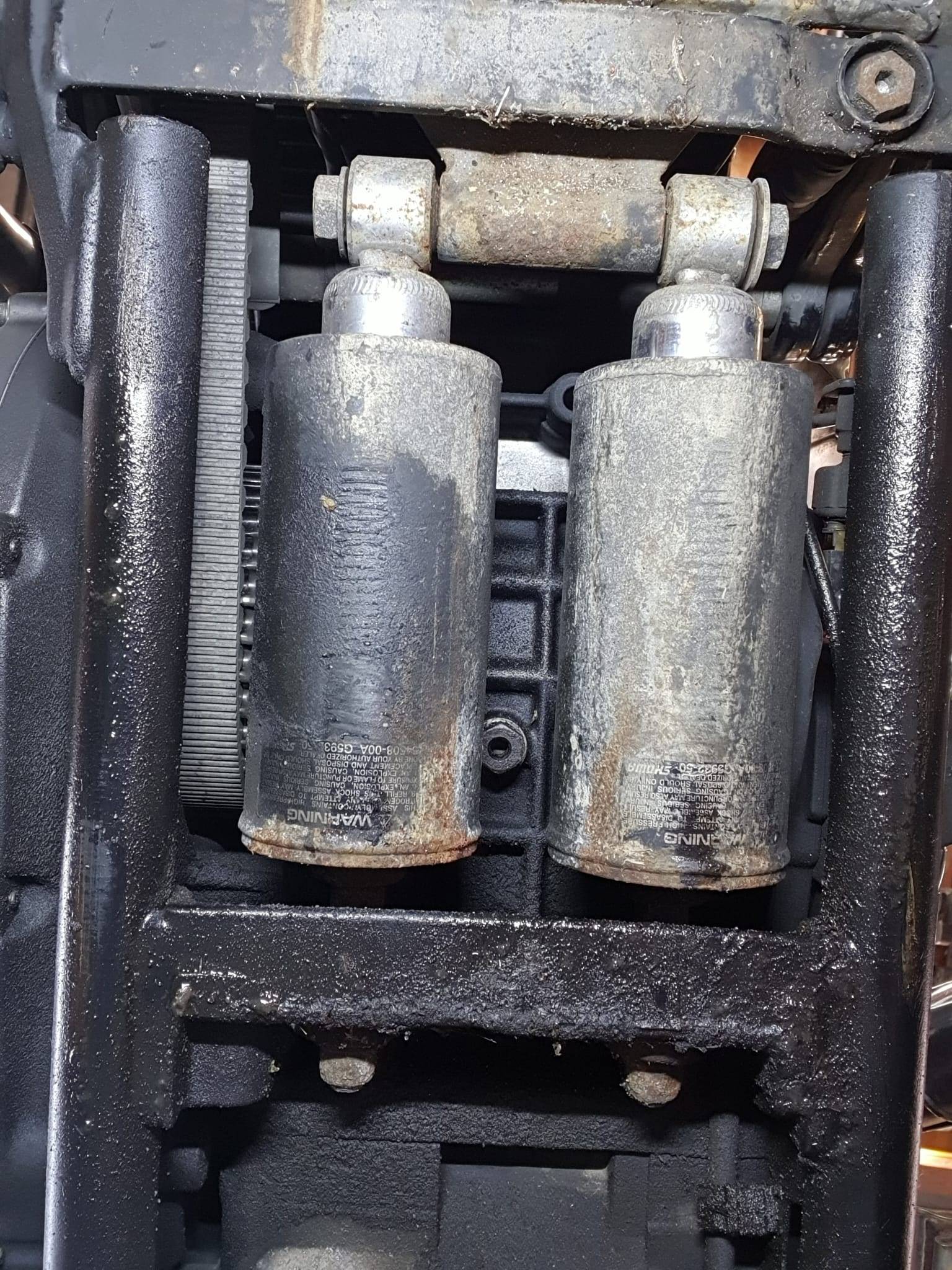

Then the engine was checked, valves adjusted, oilfilter renewed and so on, steering rack replaced with an overhauled one, brakes overhauled, suspension overhauled, and an entirely new LPG Lovato 90kW system, including new tank and new lines and electronics has been put in to replace the old Vialle LPG system.

The car is fitted with 5 pieces 2-point safety belts.

And- the car is equipped with an original (in 1980’s) after-market belt-driven ‘old school’ airco system.

Want to see more? Contact me by phone/whatsapp at +31 611008778

With a little effort and use of some lubricant in the area around the lower forkplate at the place where they are munted, the forks will slide down. I let them slip down around 2 inch under the top steering plate.

With a little effort and use of some lubricant in the area around the lower forkplate at the place where they are munted, the forks will slide down. I let them slip down around 2 inch under the top steering plate.