I added the timezone.lib plus arduino-additional code to the open-source code as GRA-AFCH made this for their IN-18 nixie clock with Arduino Mega : NixieClockShield_NCS318_V1_94_TZ.

This is a first version that works, but it might require some coding to be done, depending on where you live.

And THIS is HOW it works: The startup sequence is shown in the below video:

If you’re not in Western Europe, changing the timezone will be needed.

If I want to spend some more time on it, I can make it fully automated to work anywhere in the world and make the timezone setting done via the menu buttons, requires only a one time setting upon installation. Maybe later.

This 1ST version makes the NIXIE clock sync to UTC with the help of a to be connected standard GPS module . This was already in the code. Then, the clock changes to the correct time zone, including automatic shifting for summer- and wintertime!

In the code, I used the Western Europe timezone- and winter/summertime settings. Also, an example is given for a US timezone. Others can be derived from the examples that come with the newly added timezone.lib from https://github.com/JChristensen/Timezone

These are the available timezones:

// Australia Eastern Time Zone (Sydney, Melbourne)

TimeChangeRule aEDT = {“AEDT”, First, Sun, Oct, 2, 660}; // UTC + 11 hours

TimeChangeRule aEST = {“AEST”, First, Sun, Apr, 3, 600}; // UTC + 10 hours

Timezone ausET(aEDT, aEST);

// Moscow Standard Time (MSK, does not observe DST)

TimeChangeRule msk = {“MSK”, Last, Sun, Mar, 1, 180};

Timezone tzMSK(msk);

// Central European Time (Frankfurt, Paris)

TimeChangeRule CEST = {“CEST”, Last, Sun, Mar, 2, 120}; // Central European Summer Time

TimeChangeRule CET = {“CET “, Last, Sun, Oct, 3, 60}; // Central European Standard Time

Timezone CE(CEST, CET);

// United Kingdom (London, Belfast)

TimeChangeRule BST = {“BST”, Last, Sun, Mar, 1, 60}; // British Summer Time

TimeChangeRule GMT = {“GMT”, Last, Sun, Oct, 2, 0}; // Standard Time

Timezone UK(BST, GMT);

// UTC

TimeChangeRule utcRule = {“UTC”, Last, Sun, Mar, 1, 0}; // UTC

Timezone UTC(utcRule);

// US Eastern Time Zone (New York, Detroit)

TimeChangeRule usEDT = {“EDT”, Second, Sun, Mar, 2, -240}; // Eastern Daylight Time = UTC – 4 hours

TimeChangeRule usEST = {“EST”, First, Sun, Nov, 2, -300}; // Eastern Standard Time = UTC – 5 hours

Timezone usET(usEDT, usEST);

// US Central Time Zone (Chicago, Houston)

TimeChangeRule usCDT = {“CDT”, Second, Sun, Mar, 2, -300};

TimeChangeRule usCST = {“CST”, First, Sun, Nov, 2, -360};

Timezone usCT(usCDT, usCST);

// US Mountain Time Zone (Denver, Salt Lake City)

TimeChangeRule usMDT = {“MDT”, Second, Sun, Mar, 2, -360};

TimeChangeRule usMST = {“MST”, First, Sun, Nov, 2, -420};

Timezone usMT(usMDT, usMST);

// Arizona is US Mountain Time Zone but does not use DST

Timezone usAZ(usMST);

// US Pacific Time Zone (Las Vegas, Los Angeles)

TimeChangeRule usPDT = {“PDT”, Second, Sun, Mar, 2, -420};

TimeChangeRule usPST = {“PST”, First, Sun, Nov, 2, -480};

Timezone usPT(usPDT, usPST);

Be aware,the way I did this is a Q&D method since i have just hacked this into an existing piece of code, and only do a rewrite of the RTC’s original time after every sync to GPS with the new timezone and winter/summer time rules, so RTC will then become the new local time, either summer- or wintertime.

Since the time and applying the rules of timezone+ winter/summertime is continuously refreshed, not just the time is very stable, but also the changes between winter- and summertime and vice versa are automated.

The required arduino libraries are on the GRA-AFCH Github pagine:

https://github.com/afch/NixieClock

OR-just download the zipped Libraries from our website.

It works really well, please see the zipped file here or copy/paste the arduino code below (you will need some additional files than can only be retreived from the zip-file below, though).

NixieClockShield_NCS318_V1_94_TZ.ino

NixieClockShield_NCS318_V1_94_TZ.ino:

const String FirmwareVersion = “0196TZ”;

const char HardwareVersion[] PROGMEM = {“NCS318/568 FW 1.94TZ 2021_04_04 Jantec.nl add-on for Timezones for HW 1.x HV5122 or HV5222”};

//// This ‘TZ’ firmware addition delivers automated Summer/Winter time changes based on your local time zone settings ////

//// Jantec.nl 2023-04-04 The Netherlands, Amsterdam. Please share and re-use! ////

//// This can and may be used in any CLOCK program, with possibly specific minor alteration, due to different libraries and do on ////

//// All of my add-ons are specified in the code! Cheers, Jantec.nl, NL ////

//// The approach here is to automatically change the EEPROM hours setting according to the SUMMER/WINTER timecheme ////

//// meaning: Put in the register: a) the time zone (=normal winter time) versus UTC and b) at the switching times the summer ‘+1’ change versus ‘normal’wintertime ///

//// If the user changes the hours setting, this will be overruled at every programmed time change related to summer/ winter time

//Format _X.XXX_

//NIXIE CLOCK SHIELD NCS318/568 for HW 1.x by GRA & AFCH (fominalec@gmail.com)

//1.94 26.02.2021

//Added: Сhecking the presence of a gps receiver when turned on.

//Return to the previous gps parser

//1.92 21.01.2021

//Added: defines for GPS receiver types

//1.91 29.07.2020

//The driver has been changed to support BOTH HV5122 and HV5222 registers (switching using resistor R5222 Arduino pin No. 8)

//1.90 08.06.2020

//Fixed: GPS timezone issue: added breakTime(now(), tm) to adjustTime function at Time.cpp

//1.89 03.04.2020

//Dots sync with seconds

//1.88 26.03.2020

//GPS synchronization algorithm has been changed (again)

//1.86 23.02.2020

//GPS synchronization algorithm changed

//1.85.3 23.02.2020

//Added: DS3231 internal temperature sensor self test: 5 beeps if fail.

//1.85.2 21.02.2020

//Fixed: Bug with time zones more than +-9

// GPS parser has been replaced by NEOGPS

//1.85.1 05.01.2020

//Value of “HardwareVersion” was changed to NCS318/568

//1.85 14.06.2019

//indication is working inside interrupt (only for Arduino Mega), driver v1.3 is required

//Added: support programmable leds ws2812b

//Some performance optimizations

//1.84 08.04.2018

//LEDs functions moved to external file

//LEDs freezing while music (or sound) played.

//SPI Setup moved driver’s file

//1.83 02.08.2018 (Driver v 1.1 is required)

//Fixed: Temp. reading speed fixed

//Fixed: Dots mixed up (driver was updated to v. 1.1)

//Fixed: RGB LEDs reading from EEPROM

//Fixed: Check for entering data from GPS in range

//1.82 18.07.2018 Dual Date Format

//1.81 18.02.2018 Temp. sensor present analyze

//1.80 06.08.2017

//Added: Date and Time GPS synchronization

//1.70 30.07.2017

//Added IR remote control support (Sony RM-X151) (“MODE”, “UP”, “DOWN”)

//1.60 24_07_2017

//Added: Temperature reading mode in menu and slot machine transaction

//1.0.31 27_04_2017

//Added: antipoisoning effect – slot machine

//1.021 31.01.2017

//Added: time synchronizing each 10 seconds

//Fixed: not correct time reading from RTC while start up

//1.02 17.10.2016

//Fixed: RGB color controls

//Update to Arduino IDE 1.6.12 (Time.h replaced to TimeLib.h)

//1.01

//Added RGB LEDs lock(by UP and Down Buttons)

//Added Down and Up buttons pause and resume self testing

//25.09.2016 update to HW ver 1.1

//25.05.2016

//#define tubes8

#define tubes6

//#define tubes4

#include <SPI.h>

#include <Wire.h>

#include <ClickButton.h>

#include <TimeLib.h>

#ifndef GRA_AND_AFCH_TIME_LIB_MOD

#error The “Time (TimeLib)” library modified by GRA and AFCH must be used!

#endif

//// THIS IS NEW, related to TIMEZONE add-on:

#include <Timezone.h>//https://github.com/JChristensen/Timezone

//Central European Time (Frankfurt, Paris)

TimeChangeRule myDST = {“CEST”, Last, Sun, Mar, 26, 120}; //Central European Summer Time//Daylight time = UTC +2 hours

TimeChangeRule mySTD = {“CET “, Last, Sun, Oct, 3, 60}; //Central European Standard Time (Winter)//Daylight time = UTC +1 hour

Timezone myTZ(myDST, mySTD);

//ADD AND REPLACE THE ABOVE FOR ANY OTHER REQUIRED TIMEZONE FROM THE EXAMPLES IN JChistensen’s exaples folders

// US Eastern Time Zone (New York, Detroit)

//TimeChangeRule myDST = {“EDT”, Second, Sun, Mar, 2, -240}; //Daylight time = UTC – 4 hours

//TimeChangeRule mySTD = {“EST”, First, Sun, Nov, 2, -300}; //Daylight time = UTC – 4 hours

//Timezone myTZ(myDST, mySTD);

TimeChangeRule *tcr; //pointer to the time change rule, use to get the TZ abbrev

time_t utc;

//// end of this add-on for TIMEZONE

#include <Tone.h>

#include <EEPROM.h>

#include “doIndication318_HW1.x.h”

#include <OneWire.h>

//IR remote control /////////// START /////////////////////////////

#if defined(__AVR_ATmega1280__) || defined(__AVR_ATmega2560__)

#define GPS_SYNC_INTERVAL 1800000 // in milliseconds

//#define GPS_SYNC_INTERVAL 180000 //3 minutes

unsigned long Last_Time_GPS_Sync = 0;

//bool GPS_Sync_Flag = false;

//uint32_t GPS_Sync_Interval=120000; // 2 minutes

uint32_t GPS_Sync_Interval = 60000; // first try = 1 minute

uint32_t MillsNow=0;

#define TIME_TO_TRY 60000 //1 minute

bool AttMsgWasShowed=false;

#define GPS_BUFFER_LENGTH 83

char GPS_Package[GPS_BUFFER_LENGTH];

byte GPS_position = 0;

struct GPS_DATE_TIME

{

byte GPS_hours;

byte GPS_minutes;

byte GPS_seconds;

byte GPS_day;

byte GPS_mounth;

int GPS_year;

bool GPS_Valid_Data = false;

unsigned long GPS_Data_Parsed_time;

};

GPS_DATE_TIME GPS_Date_Time;

#define PreZero(digit) ((abs(digit)<10)?”0″+String(abs(digit)):String(abs(digit)))

#include <IRremote.h>

int RECV_PIN = 4;

IRrecv irrecv(RECV_PIN);

decode_results IRresults;

// buttons codes for remote controller Sony RM-X151

#define IR_BUTTON_UP_CODE 0x6621

#define IR_BUTTON_DOWN_CODE 0x2621

#define IR_BUTTON_MODE_CODE 0x7121

class IRButtonState

{

public:

int PAUSE_BETWEEN_PACKETS = 50;

int PACKETS_QTY_IN_LONG_PRESS = 18;

private:

bool Flag = 0;

byte CNT_packets = 0;

unsigned long lastPacketTime = 0;

bool START_TIMER = false;

int _buttonCode;

public: IRButtonState::IRButtonState(int buttonCode)

{

_buttonCode = buttonCode;

}

public: int IRButtonState::checkButtonState(int receivedCode)

{

if (((millis() – lastPacketTime) > PAUSE_BETWEEN_PACKETS) && (START_TIMER == true))

{

START_TIMER = false;

if (CNT_packets >= 2) {

Flag = 0;

CNT_packets = 0;

START_TIMER = false;

return 1;

}

else {

Flag = 0;

CNT_packets = 0;

return 0;

}

}

else

{

if (receivedCode == _buttonCode) { Flag = 1;}

else

{

if (!(Flag == 1)) {return 0;}

else

{

if (!(receivedCode == 0xFFFFFFFF)) {return 0;}

}

}

CNT_packets++;

lastPacketTime = millis();

START_TIMER = true;

if (CNT_packets >= PACKETS_QTY_IN_LONG_PRESS) {

Flag = 0;

CNT_packets = 0;

START_TIMER = false;

return -1;

}

else {return 0;}

}

}

};

IRButtonState IRModeButton(IR_BUTTON_MODE_CODE);

IRButtonState IRUpButton(IR_BUTTON_UP_CODE);

IRButtonState IRDownButton(IR_BUTTON_DOWN_CODE);

#endif

int ModeButtonState = 0;

int UpButtonState = 0;

int DownButtonState = 0;

//IR remote control /////////// START /////////////////////////////

/*#define GPS_BUFFER_LENGTH 83

char GPS_Package[GPS_BUFFER_LENGTH];

byte GPS_position=0;

struct GPS_DATE_TIME

{

byte GPS_hours;

byte GPS_minutes;

byte GPS_seconds;

byte GPS_day;

byte GPS_mounth;

int GPS_year;

bool GPS_Valid_Data=false;

unsigned long GPS_Data_Parsed_time;

};

*/

//GPS_DATE_TIME GPS_Date_Time;

unsigned long GPS_Data_Parsed_time;

boolean UD, LD; // DOTS control;

byte data[12];

byte addr[8];

int celsius, fahrenheit;

#define RedLedPin 9 //MCU WDM output for red LEDs 9-g

#define GreenLedPin 6 //MCU WDM output for green LEDs 6-b

#define BlueLedPin 3 //MCU WDM output for blue LEDs 3-r

#define pinSet A0

#define pinUp A2

#define pinDown A1

//#define pinBuzzer 2

const byte pinBuzzer = 2; // pomenyal

#define pinUpperDots 12 //HIGH value light a dots

#define pinLowerDots 8 //HIGH value light a dots

#define pinTemp 7

bool RTC_present;

#define US_DateFormat 1

#define EU_DateFormat 0

//bool DateFormat=EU_DateFormat;

OneWire ds(pinTemp);

bool TempPresent = false;

#define CELSIUS 0

#define FAHRENHEIT 1

String stringToDisplay = “000000”; // Content of this string will be displayed on tubes (must be 6 chars length)

int menuPosition = 0;

// 0 – time

// 1 – date

// 2 – alarm

// 3 – 12/24 hours mode

// 4 – Temperature

// 5 – TimeZone* (Only for Ardiono Mega)

byte blinkMask = B00000000; //bit mask for blinkin digits (1 – blink, 0 – constant light)

int blankMask = B00000000; //bit mask for digits (1 – off, 0 – on)

byte dotPattern = B00000000; //bit mask for separeting dots (1 – on, 0 – off)

//B10000000 – upper dots

//B01000000 – lower dots

#define DS1307_ADDRESS 0x68

byte zero = 0x00; //workaround for issue #527

int RTC_hours, RTC_minutes, RTC_seconds, RTC_day, RTC_month, RTC_year, RTC_day_of_week;

#define TimeIndex 0

#define DateIndex 1

#define AlarmIndex 2

#define hModeIndex 3

#define TemperatureIndex 4

#define TimeZoneIndex 5

#define TimeHoursIndex 6

#define TimeMintuesIndex 7

#define TimeSecondsIndex 8

#define DateFormatIndex 9

#define DateDayIndex 10

#define DateMonthIndex 11

#define DateYearIndex 12

#define AlarmHourIndex 13

#define AlarmMinuteIndex 14

#define AlarmSecondIndex 15

#define Alarm01 16

#define hModeValueIndex 17

#define DegreesFormatIndex 18

#define HoursOffsetIndex 19

#define FirstParent TimeIndex

#define LastParent TimeZoneIndex

#define SettingsCount (HoursOffsetIndex+1)

#define NoParent 0

#define NoChild 0

//——————————-0——–1——–2——-3——–4——–5——–6——–7——–8——–9———-10——-11———12———13——-14——-15———16———17——–18———-19

// names: Time, Date, Alarm, 12/24, Temperature,TimeZone,hours, mintues, seconds, DateFormat, day, month, year, hour, minute, second alarm01 hour_format Deg.FormIndex HoursOffset

// 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

int parent[SettingsCount] = {NoParent, NoParent, NoParent, NoParent,NoParent,NoParent,1, 1, 1, 2, 2, 2, 2, 3, 3, 3, 3, 4, 5, 6};

int firstChild[SettingsCount] = {6, 9, 13, 17, 18, 19, 0, 0, 0, NoChild, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0};

int lastChild[SettingsCount] = { 8, 12, 16, 17, 18, 19, 0, 0, 0, NoChild, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0};

int value[SettingsCount] = { 0, 0, 0, 0, 0, 0, 0, 0, 0, EU_DateFormat, 0, 0, 0, 0, 0, 0, 0, 24, 0, 2};

int maxValue[SettingsCount] = { 0, 0, 0, 0, 0, 0, 23, 59, 59, US_DateFormat, 31, 12, 99, 23, 59, 59, 1, 24, FAHRENHEIT, 14};

int minValue[SettingsCount] = { 0, 0, 0, 12, 0, 0, 00, 00, 00, EU_DateFormat, 1, 1, 00, 00, 00, 00, 0, 12, CELSIUS, -12};

int blinkPattern[SettingsCount] = {

B00000000, //0

B00000000, //1

B00000000, //2

B00000000, //3

B00000000, //4

B00000000, //5

B00000011, //6

B00001100, //7

B00110000, //8

B00111111, //9

B00000011, //10

B00001100, //11

B00110000, //12

B00000011, //13

B00001100, //14

B00110000, //15

B11000000, //16

B00001100, //17

B00111111, //18

B00000011, //19

};

bool editMode = false;

long downTime = 0;

long upTime = 0;

const long settingDelay = 150;

bool BlinkUp = false;

bool BlinkDown = false;

unsigned long enteringEditModeTime = 0;

bool RGBLedsOn = true;

#define RGBLEDsEEPROMAddress 0

#define HourFormatEEPROMAddress 1

#define AlarmTimeEEPROMAddress 2 //3,4,5

#define AlarmArmedEEPROMAddress 6

#define LEDsLockEEPROMAddress 7

#define LEDsRedValueEEPROMAddress 8

#define LEDsGreenValueEEPROMAddress 9

#define LEDsBlueValueEEPROMAddress 10

#define DegreesFormatEEPROMAddress 11

#define HoursOffsetEEPROMAddress 12

#define DateFormatEEPROMAddress 13

//buttons pins declarations

ClickButton setButton(pinSet, LOW, CLICKBTN_PULLUP);

ClickButton upButton(pinUp, LOW, CLICKBTN_PULLUP);

ClickButton downButton(pinDown, LOW, CLICKBTN_PULLUP);

///////////////////

Tone tone1;

#define isdigit(n) (n >= ‘0’ && n <= ‘9’)

//char *song = “MissionImp:d=16,o=6,b=95:32d,32d#,32d,32d#,32d,32d#,32d,32d#,32d,32d,32d#,32e,32f,32f#,32g,g,8p,g,8p,a#,p,c7,p,g,8p,g,8p,f,p,f#,p,g,8p,g,8p,a#,p,c7,p,g,8p,g,8p,f,p,f#,p,a#,g,2d,32p,a#,g,2c#,32p,a#,g,2c,a#5,8c,2p,32p,a#5,g5,2f#,32p,a#5,g5,2f,32p,a#5,g5,2e,d#,8d”;

char *song = “PinkPanther:d=4,o=5,b=160:8d#,8e,2p,8f#,8g,2p,8d#,8e,16p,8f#,8g,16p,8c6,8b,16p,8d#,8e,16p,8b,2a#,2p,16a,16g,16e,16d,2e”;

//char *song=”VanessaMae:d=4,o=6,b=70:32c7,32b,16c7,32g,32p,32g,32p,32d#,32p,32d#,32p,32c,32p,32c,32p,32c7,32b,16c7,32g#,32p,32g#,32p,32f,32p,16f,32c,32p,32c,32p,32c7,32b,16c7,32g,32p,32g,32p,32d#,32p,32d#,32p,32c,32p,32c,32p,32g,32f,32d#,32d,32c,32d,32d#,32c,32d#,32f,16g,8p,16d7,32c7,32d7,32a#,32d7,32a,32d7,32g,32d7,32d7,32p,32d7,32p,32d7,32p,16d7,32c7,32d7,32a#,32d7,32a,32d7,32g,32d7,32d7,32p,32d7,32p,32d7,32p,32g,32f,32d#,32d,32c,32d,32d#,32c,32d#,32f,16c”;

//char *song=”DasBoot:d=4,o=5,b=100:d#.4,8d4,8c4,8d4,8d#4,8g4,a#.4,8a4,8g4,8a4,8a#4,8d,2f.,p,f.4,8e4,8d4,8e4,8f4,8a4,c.,8b4,8a4,8b4,8c,8e,2g.,2p”;

//char *song=”Scatman:d=4,o=5,b=200:8b,16b,32p,8b,16b,32p,8b,2d6,16p,16c#.6,16p.,8d6,16p,16c#6,8b,16p,8f#,2p.,16c#6,8p,16d.6,16p.,16c#6,16b,8p,8f#,2p,32p,2d6,16p,16c#6,8p,16d.6,16p.,16c#6,16a.,16p.,8e,2p.,16c#6,8p,16d.6,16p.,16c#6,16b,8p,8b,16b,32p,8b,16b,32p,8b,2d6,16p,16c#.6,16p.,8d6,16p,16c#6,8b,16p,8f#,2p.,16c#6,8p,16d.6,16p.,16c#6,16b,8p,8f#,2p,32p,2d6,16p,16c#6,8p,16d.6,16p.,16c#6,16a.,16p.,8e,2p.,16c#6,8p,16d.6,16p.,16c#6,16a,8p,8e,2p,32p,16f#.6,16p.,16b.,16p.”;

//char *song=”Popcorn:d=4,o=5,b=160:8c6,8a#,8c6,8g,8d#,8g,c,8c6,8a#,8c6,8g,8d#,8g,c,8c6,8d6,8d#6,16c6,8d#6,16c6,8d#6,8d6,16a#,8d6,16a#,8d6,8c6,8a#,8g,8a#,c6″;

//char *song=”WeWishYou:d=4,o=5,b=200:d,g,8g,8a,8g,8f#,e,e,e,a,8a,8b,8a,8g,f#,d,d,b,8b,8c6,8b,8a,g,e,d,e,a,f#,2g,d,g,8g,8a,8g,8f#,e,e,e,a,8a,8b,8a,8g,f#,d,d,b,8b,8c6,8b,8a,g,e,d,e,a,f#,1g,d,g,g,g,2f#,f#,g,f#,e,2d,a,b,8a,8a,8g,8g,d6,d,d,e,a,f#,2g”;

#define OCTAVE_OFFSET 0

char *p;

int notes[] = { 0,

NOTE_C4, NOTE_CS4, NOTE_D4, NOTE_DS4, NOTE_E4, NOTE_F4, NOTE_FS4, NOTE_G4, NOTE_GS4, NOTE_A4, NOTE_AS4, NOTE_B4,

NOTE_C5, NOTE_CS5, NOTE_D5, NOTE_DS5, NOTE_E5, NOTE_F5, NOTE_FS5, NOTE_G5, NOTE_GS5, NOTE_A5, NOTE_AS5, NOTE_B5,

NOTE_C6, NOTE_CS6, NOTE_D6, NOTE_DS6, NOTE_E6, NOTE_F6, NOTE_FS6, NOTE_G6, NOTE_GS6, NOTE_A6, NOTE_AS6, NOTE_B6,

NOTE_C7, NOTE_CS7, NOTE_D7, NOTE_DS7, NOTE_E7, NOTE_F7, NOTE_FS7, NOTE_G7, NOTE_GS7, NOTE_A7, NOTE_AS7, NOTE_B7

};

int fireforks[] = {0, 0, 1, //1

-1, 0, 0, //2

0, 1, 0, //3

0, 0, -1, //4

1, 0, 0, //5

0, -1, 0

}; //array with RGB rules (0 – do nothing, -1 – decrese, +1 – increse

void setRTCDateTime(byte h, byte m, byte s, byte d, byte mon, byte y, byte w = 1);

int functionDownButton = 0;

int functionUpButton = 0;

bool LEDsLock = false;

//antipoisoning transaction

bool modeChangedByUser = false;

bool transactionInProgress = false; //antipoisoning transaction

#define timeModePeriod 60000

#define dateModePeriod 5000

long modesChangePeriod = timeModePeriod;

//end of antipoisoning transaction

bool GPS_sync_flag=false;

extern const int LEDsDelay;

/*******************************************************************************************************

Init Programm

*******************************************************************************************************/

void setup()

{

Wire.begin();

//setRTCDateTime(23,40,00,25,7,15,1);

Serial.begin(115200);

#if defined(__AVR_ATmega1280__) || defined(__AVR_ATmega2560__)

Serial1.begin(9600);

digitalWrite(19, HIGH);

#endif

if (EEPROM.read(HourFormatEEPROMAddress) != 12) value[hModeValueIndex] = 24; else value[hModeValueIndex] = 12;

if (EEPROM.read(RGBLEDsEEPROMAddress) != 0) RGBLedsOn = true; else RGBLedsOn = false;

if (EEPROM.read(AlarmTimeEEPROMAddress) == 255) value[AlarmHourIndex] = 0; else value[AlarmHourIndex] = EEPROM.read(AlarmTimeEEPROMAddress);

if (EEPROM.read(AlarmTimeEEPROMAddress + 1) == 255) value[AlarmMinuteIndex] = 0; else value[AlarmMinuteIndex] = EEPROM.read(AlarmTimeEEPROMAddress + 1);

if (EEPROM.read(AlarmTimeEEPROMAddress + 2) == 255) value[AlarmSecondIndex] = 0; else value[AlarmSecondIndex] = EEPROM.read(AlarmTimeEEPROMAddress + 2);

if (EEPROM.read(AlarmArmedEEPROMAddress) == 255) value[Alarm01] = 0; else value[Alarm01] = EEPROM.read(AlarmArmedEEPROMAddress);

if (EEPROM.read(LEDsLockEEPROMAddress) == 255) LEDsLock = false; else LEDsLock = EEPROM.read(LEDsLockEEPROMAddress);

if (EEPROM.read(DegreesFormatEEPROMAddress) == 255) value[DegreesFormatIndex] = CELSIUS; else value[DegreesFormatIndex] = EEPROM.read(DegreesFormatEEPROMAddress);

if (EEPROM.read(HoursOffsetEEPROMAddress) == 255) value[HoursOffsetIndex] = value[HoursOffsetIndex]; else value[HoursOffsetIndex] = EEPROM.read(HoursOffsetEEPROMAddress) + minValue[HoursOffsetIndex];

//// needed to set this HoursOffsetIndex variable to 0 since we will use the timezone lib (local timezone and summer/winter time add-ons by Jantec.nl)

value[HoursOffsetIndex] = 0;

EEPROM.write(HoursOffsetEEPROMAddress, 0);

if (EEPROM.read(DateFormatEEPROMAddress) == 255) value[DateFormatIndex] = value[DateFormatIndex]; else value[DateFormatIndex] = EEPROM.read(DateFormatEEPROMAddress);

//Serial.print(F(“led lock=”));

//Serial.println(LEDsLock);

pinMode(RedLedPin, OUTPUT);

pinMode(GreenLedPin, OUTPUT);

pinMode(BlueLedPin, OUTPUT);

tone1.begin(pinBuzzer);

song = parseSong(song);

pinMode(LEpin, OUTPUT);

// SPI setup

SPISetup();

LEDsSetup();

//buttons pins inits

pinMode(pinSet, INPUT_PULLUP);

pinMode(pinUp, INPUT_PULLUP);

pinMode(pinDown, INPUT_PULLUP);

////////////////////////////

pinMode(pinBuzzer, OUTPUT);

//buttons objects inits

setButton.debounceTime = 20; // Debounce timer in ms

setButton.multiclickTime = 30; // Time limit for multi clicks

setButton.longClickTime = 2000; // time until “held-down clicks” register

upButton.debounceTime = 20; // Debounce timer in ms

upButton.multiclickTime = 30; // Time limit for multi clicks

upButton.longClickTime = 2000; // time until “held-down clicks” register

downButton.debounceTime = 20; // Debounce timer in ms

downButton.multiclickTime = 30; // Time limit for multi clicks

downButton.longClickTime = 2000; // time until “held-down clicks” register

#if defined(__AVR_ATmega1280__) || defined(__AVR_ATmega2560__)

timerSetup();

#endif

//!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

doTest();

//!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

if (LEDsLock == 1)

{

setLEDsFromEEPROM();

}

getRTCTime();

byte prevSeconds = RTC_seconds;

unsigned long RTC_ReadingStartTime = millis();

RTC_present = true;

while (prevSeconds == RTC_seconds)

{

getRTCTime();

//Serial.println(RTC_seconds);

if ((millis() – RTC_ReadingStartTime) > 3000)

{

#ifdef DEBUG

Serial.println(F(“Warning! RTC DON’T RESPOND!”));

#endif

RTC_present = false;

break;

}

}

setTime(RTC_hours, RTC_minutes, RTC_seconds, RTC_day, RTC_month, RTC_year);

#if defined(__AVR_ATmega1280__) || defined(__AVR_ATmega2560__)

irrecv.blink13(false);

irrecv.enableIRIn(); // Start the receiver

#endif

//// add-ons for TIMEZONE

time_t utc = now();

time_t local = myTZ.toLocal(utc, &tcr);

Serial.println();

printDateTime(utc, “UTC”);

printDateTime(local, tcr -> abbrev);

delay(1000);//was 10000

//// end of add-ons for TIMEZONE

}

int rotator = 0; //index in array with RGB “rules” (increse by one on each 255 cycles)

int cycle = 0; //cycles counter

int RedLight = 255;

int GreenLight = 0;

int BlueLight = 0;

unsigned long prevTime = 0; // time of lase tube was lit

unsigned long prevTime4FireWorks = 0; //time of last RGB changed

//int minuteL=0; //младшая цифра минут

/***************************************************************************************************************

MAIN Programm

***************************************************************************************************************/

void loop() {

if (((millis() % 10000) == 0) && (RTC_present)) //synchronize with RTC every 10 seconds

{

getRTCTime();

setTime(RTC_hours, RTC_minutes, RTC_seconds, RTC_day, RTC_month, RTC_year);

// 4 lines of time zone & winter/summer time additions by Jantec.nl 2023 0404

time_t utc = now();

time_t local = myTZ.toLocal(utc, &tcr);

setTime(myTZ.toLocal(utc, &tcr));

EEPROM.write(DateFormatEEPROMAddress, value[myTZ.toLocal(utc, &tcr)]);

//Serial.println(F(“Sync”));

}

#if defined(__AVR_ATmega1280__) || defined(__AVR_ATmega2560__)

MillsNow=millis();

if ((MillsNow – Last_Time_GPS_Sync) > GPS_Sync_Interval)

{

//GPS_Sync_Interval = GPS_SYNC_INTERVAL; // <—-!

//GPS_Sync_Flag = 0;

if (AttMsgWasShowed==false)

{

Serial.println(F(“Attempt to sync with GPS.”));

AttMsgWasShowed=true;

}

GetDataFromSerial1();

//SyncWithGPS();

}

if ((MillsNow – Last_Time_GPS_Sync) > GPS_Sync_Interval + TIME_TO_TRY)

{

Last_Time_GPS_Sync=MillsNow; //if it is not possible to synchronize within the allotted time TIME_TO_TRY, then we postpone attempts to the next time interval.

//GPS_Sync_Flag = 1;

//GPS_Sync_Interval = GPS_SYNC_INTERVAL;

Serial.println(F(“All attempts were unsuccessful.”));

AttMsgWasShowed=false;

}

IRresults.value = 0;

if (irrecv.decode(&IRresults)) {

Serial.println(IRresults.value, HEX);

irrecv.resume(); // Receive the next value

}

ModeButtonState = IRModeButton.checkButtonState(IRresults.value);

if (ModeButtonState == 1) Serial.println(F(“Mode short”));

if (ModeButtonState == -1) Serial.println(F(“Mode long….”));

UpButtonState = IRUpButton.checkButtonState(IRresults.value);

if (UpButtonState == 1) Serial.println(F(“Up short”));

if (UpButtonState == -1) Serial.println(F(“Up long….”));

DownButtonState = IRDownButton.checkButtonState(IRresults.value);

if (DownButtonState == 1) Serial.println(F(“Down short”));

if (DownButtonState == -1) Serial.println(F(“Down long….”));

#else

ModeButtonState=0;

UpButtonState=0;

DownButtonState=0;

#endif

p = playmusic(p);

if ((millis() – prevTime4FireWorks) > LEDsDelay)

{

rotateFireWorks(); //change color (by 1 step)

prevTime4FireWorks = millis();

}

if ((menuPosition == TimeIndex) || (modeChangedByUser == false) ) modesChanger();

#if defined (__AVR_ATmega328P__)

doIndication();

#endif

setButton.Update();

upButton.Update();

downButton.Update();

if (editMode == false)

{

blinkMask = B00000000;

} else if ((millis() – enteringEditModeTime) > 60000)

{

editMode = false;

menuPosition = firstChild[menuPosition];

blinkMask = blinkPattern[menuPosition];

}

if ((setButton.clicks > 0) || (ModeButtonState == 1)) //short click

{

modeChangedByUser = true;

p = 0; //shut off music )))

tone1.play(1000, 100);

enteringEditModeTime = millis();

/*if (value[DateFormatIndex] == US_DateFormat)

{

//if (menuPosition == )

} else */

menuPosition = menuPosition + 1;

#if defined (__AVR_ATmega328P__)

if (menuPosition == TimeZoneIndex) menuPosition++;// skip TimeZone for Arduino Uno

#endif

if (menuPosition == LastParent + 1) menuPosition = TimeIndex;

/*Serial.print(F(“menuPosition=”));

Serial.println(menuPosition);

Serial.print(F(“value=”));

Serial.println(value[menuPosition]);*/

blinkMask = blinkPattern[menuPosition];

if ((parent[menuPosition – 1] != 0) and (lastChild[parent[menuPosition – 1] – 1] == (menuPosition – 1))) //exit from edit mode

{

if ((parent[menuPosition – 1] – 1 == 1) && (!isValidDate()))

{

menuPosition = DateDayIndex;

return;

}

editMode = false;

menuPosition = parent[menuPosition – 1] – 1;

if (menuPosition == TimeIndex) setTime(value[TimeHoursIndex], value[TimeMintuesIndex], value[TimeSecondsIndex], day(), month(), year());

if (menuPosition == DateIndex)

{

#ifdef DEBUG

Serial.print(F(“Day:”));

Serial.println(value[DateDayIndex]);

Serial.print(F(“Month:”));

Serial.println(value[DateMonthIndex]);

#endif

setTime(hour(), minute(), second(), value[DateDayIndex], value[DateMonthIndex], 2000 + value[DateYearIndex]);

EEPROM.write(DateFormatEEPROMAddress, value[DateFormatIndex]);

}

if (menuPosition == AlarmIndex) {

EEPROM.write(AlarmTimeEEPROMAddress, value[AlarmHourIndex]);

EEPROM.write(AlarmTimeEEPROMAddress + 1, value[AlarmMinuteIndex]);

EEPROM.write(AlarmTimeEEPROMAddress + 2, value[AlarmSecondIndex]);

EEPROM.write(AlarmArmedEEPROMAddress, value[Alarm01]);

};

if (menuPosition == hModeIndex) EEPROM.write(HourFormatEEPROMAddress, value[hModeValueIndex]);

if (menuPosition == TemperatureIndex)

{

EEPROM.write(DegreesFormatEEPROMAddress, value[DegreesFormatIndex]);

}

if (menuPosition == TimeZoneIndex) EEPROM.write(HoursOffsetEEPROMAddress, value[HoursOffsetIndex] – minValue[HoursOffsetIndex]);

//if (menuPosition == hModeIndex) EEPROM.write(HourFormatEEPROMAddress, value[hModeValueIndex]);

setRTCDateTime(hour(), minute(), second(), day(), month(), year() % 1000, 1);

return;

} //end exit from edit mode

/*Serial.print(“menu pos=”);

Serial.println(menuPosition);

Serial.print(“DateFormat”);

Serial.println(value[DateFormatIndex]);*/

if ((menuPosition != HoursOffsetIndex) &&

(menuPosition != DateFormatIndex) &&

(menuPosition != DateDayIndex)) value[menuPosition] = extractDigits(blinkMask);

}

if ((setButton.clicks < 0) || (ModeButtonState == -1)) //long click

{

tone1.play(1000, 100);

if (!editMode)

{

enteringEditModeTime = millis();

if (menuPosition == TimeIndex) stringToDisplay = PreZero(hour()) + PreZero(minute()) + PreZero(second()); //temporary enabled 24 hour format while settings

}

if (menuPosition == DateIndex)

{

// Serial.println(“DateEdit”);

value[DateDayIndex] = day();

value[DateMonthIndex] = month();

value[DateYearIndex] = year() % 1000;

if (value[DateFormatIndex] == EU_DateFormat) stringToDisplay=PreZero(value[DateDayIndex])+PreZero(value[DateMonthIndex])+PreZero(value[DateYearIndex]);

else stringToDisplay=PreZero(value[DateMonthIndex])+PreZero(value[DateDayIndex])+PreZero(value[DateYearIndex]);

//Serial.print(“str=”);

// Serial.println(stringToDisplay);

}

menuPosition = firstChild[menuPosition];

if (menuPosition == AlarmHourIndex) {

value[Alarm01] = 1; /*digitalWrite(pinUpperDots, HIGH);*/dotPattern = B10000000;

}

editMode = !editMode;

blinkMask = blinkPattern[menuPosition];

if ((menuPosition != DegreesFormatIndex) &&

(menuPosition != HoursOffsetIndex) &&

(menuPosition != DateFormatIndex))

value[menuPosition] = extractDigits(blinkMask);

/*Serial.print(F(“menuPosition=”));

Serial.println(menuPosition);

Serial.print(F(“value=”));

Serial.println(value[menuPosition]); */

}

if (upButton.clicks != 0) functionUpButton = upButton.clicks;

if ((upButton.clicks > 0) || (UpButtonState == 1))

{

modeChangedByUser = true;

p = 0; //shut off music )))

tone1.play(1000, 100);

incrementValue();

if (!editMode)

{

LEDsLock = false;

EEPROM.write(LEDsLockEEPROMAddress, 0);

}

}

if (functionUpButton == -1 && upButton.depressed == true)

{

BlinkUp = false;

if (editMode == true)

{

if ( (millis() – upTime) > settingDelay)

{

upTime = millis();// + settingDelay;

incrementValue();

}

}

} else BlinkUp = true;

if (downButton.clicks != 0) functionDownButton = downButton.clicks;

if ((downButton.clicks > 0) || (DownButtonState == 1))

{

modeChangedByUser = true;

p = 0; //shut off music )))

tone1.play(1000, 100);

dicrementValue();

if (!editMode)

{

LEDsLock = true;

EEPROM.write(LEDsLockEEPROMAddress, 1);

EEPROM.write(LEDsRedValueEEPROMAddress, RedLight);

EEPROM.write(LEDsGreenValueEEPROMAddress, GreenLight);

EEPROM.write(LEDsBlueValueEEPROMAddress, BlueLight);

/*Serial.println(F(“Store to EEPROM:”));

Serial.print(F(“RED=”));

Serial.println(RedLight);

Serial.print(F(“GREEN=”));

Serial.println(GreenLight);

Serial.print(F(“Blue=”));

Serial.println(BlueLight);*/

}

}

if (functionDownButton == -1 && downButton.depressed == true)

{

BlinkDown = false;

if (editMode == true)

{

if ( (millis() – downTime) > settingDelay)

{

downTime = millis();// + settingDelay;

dicrementValue();

}

}

} else BlinkDown = true;

if (!editMode)

{

if ((upButton.clicks < 0) || (UpButtonState == -1))

{

tone1.play(1000, 100);

RGBLedsOn = true;

EEPROM.write(RGBLEDsEEPROMAddress, 1);

#ifdef DEBUG

Serial.println(F(“RGB=on”));

#endif

setLEDsFromEEPROM();

}

if ((downButton.clicks < 0) || (DownButtonState == -1))

{

tone1.play(1000, 100);

RGBLedsOn = false;

EEPROM.write(RGBLEDsEEPROMAddress, 0);

#ifdef DEBUG

Serial.println(F(“RGB=off”));

#endif

}

}

static bool updateDateTime = false;

float curTemp=0;

switch (menuPosition)

{

case TimeIndex: //time mode

if (!transactionInProgress) stringToDisplay = updateDisplayString();

doDotBlink();

checkAlarmTime();

blankMask = B00000000;

break;

case DateIndex: //date mode

if (!transactionInProgress) stringToDisplay = updateDateString();

dotPattern = B01000000; //turn on lower dots

checkAlarmTime();

blankMask = B00000000;

break;

case AlarmIndex: //alarm mode

//stringToDisplay=”000000″;

//unsigned long execTime;

//execTime=micros();

stringToDisplay = PreZero(value[AlarmHourIndex]) + PreZero(value[AlarmMinuteIndex]) + PreZero(value[AlarmSecondIndex]);

blankMask = B00000000;

if (value[Alarm01] == 1) dotPattern = B10000000; //turn on upper dots

else

{

dotPattern = B00000000; //turn off upper dots

}

//execTime=micros()-execTime;

//Serial.println(execTime);

checkAlarmTime();

break;

case hModeIndex: //12/24 hours mode

stringToDisplay = “00” + String(value[hModeValueIndex]) + “00”;

blankMask = B00110011;

dotPattern = B00000000; //turn off all dots

checkAlarmTime();

break;

case TemperatureIndex: //missed break

case DegreesFormatIndex:

if (!transactionInProgress)

{

curTemp=getTemperature(value[DegreesFormatIndex]);

stringToDisplay = updateTemperatureString(curTemp);

if (value[DegreesFormatIndex] == CELSIUS)

{

blankMask = B00110001;

dotPattern = B01000000;

}

else

{

blankMask = B00100011;

dotPattern = B00000000;

}

}

if (curTemp < 0) dotPattern |= B10000000;

else dotPattern &= B01111111;

break;

case TimeZoneIndex:

case HoursOffsetIndex:

stringToDisplay = String(PreZero(value[HoursOffsetIndex])) + “0000”;

blankMask = B00001111;

if (value[HoursOffsetIndex]>=0) dotPattern = B00000000; //turn off all dots

else dotPattern = B10000000; //turn on upper dots

break;

case DateFormatIndex:

if (value[DateFormatIndex] == EU_DateFormat)

{

stringToDisplay=”311299″;

blinkPattern[DateDayIndex]=B00000011;

blinkPattern[DateMonthIndex]=B00001100;

}

else

{

stringToDisplay=”123199″;

blinkPattern[DateDayIndex]=B00001100;

blinkPattern[DateMonthIndex]=B00000011;

}

break;

case DateDayIndex:

case DateMonthIndex:

case DateYearIndex:

if (value[DateFormatIndex] == EU_DateFormat) stringToDisplay=PreZero(value[DateDayIndex])+PreZero(value[DateMonthIndex])+PreZero(value[DateYearIndex]);

else stringToDisplay=PreZero(value[DateMonthIndex])+PreZero(value[DateDayIndex])+PreZero(value[DateYearIndex]);

break;

}

// IRresults.value=0;

}

#if defined (__AVR_ATmega328P__)

String PreZero(int digit)

{

digit=abs(digit);

if (digit < 10) return String(“0”) + String(digit);

//if (digit < 10) return “0” + String(digit);

else return String(digit);

}

#endif

String updateDisplayString()

{

static int prevS=-1;

if (second()!=prevS)

{

prevS=second();

return getTimeNow();

} else return stringToDisplay;

}

String getTimeNow()

{

if (value[hModeValueIndex] == 24) return PreZero(hour()) + PreZero(minute()) + PreZero(second());

else return PreZero(hourFormat12()) + PreZero(minute()) + PreZero(second());

}

//// add-on void for TIMEZONE ////////////////////////////////////////////////////////////

// format and print a time_t value, with a time zone appended.

void printDateTime(time_t t, const char *tz)

{

char buf[32];

char m[4]; // temporary storage for month string (DateStrings.cpp uses shared buffer)

strcpy(m, monthShortStr(month(t)));

sprintf(buf, “%.2d:%.2d:%.2d %s %.2d %s %d %s”,

hour(t), minute(t), second(t), dayShortStr(weekday(t)), day(t), m, year(t), tz);

Serial.println(buf);

}

/////// Jantec.nl 2023-04-04 The Netherlands, Amsterdam. Please share and re-use! ////////

void doTest()

{

Serial.print(F(“Firmware version: “));

Serial.println(FirmwareVersion.substring(1,2)+”.”+FirmwareVersion.substring(2,5));

for (byte k = 0; k < strlen_P(HardwareVersion); k++) {

Serial.print((char)pgm_read_byte_near(HardwareVersion + k));

}

Serial.println();

#ifdef DEBUG

Serial.println(F(“Start Test”));

#endif

p=song;

parseSong(p);

//p=0; //need to be deleted

LEDsTest();

#if defined(__AVR_ATmega1280__) || defined(__AVR_ATmega2560__)

if (Serial1.available() > 20) Serial.println(F(“GPS detected”));

else Serial.println(F(“GPS NOT detected!”));

#endif

#ifdef tubes8

String testStringArray[11]={“00000000″,”11111111″,”22222222″,”33333333″,”44444444″,”55555555″,”66666666″,”77777777″,”88888888″,”99999999″,””};

testStringArray[10]=FirmwareVersion+”00″;

#endif

#ifdef tubes6

String testStringArray[11]={“000000″,”111111″,”222222″,”333333″,”444444″,”555555″,”666666″,”777777″,”888888″,”999999″,””};

testStringArray[10]=FirmwareVersion;

#endif

int dlay=500;

bool test=1;

byte strIndex=-1;

unsigned long startOfTest=millis()+1000; //disable delaying in first iteration

bool digitsLock=false;

while (test)

{

if (digitalRead(pinDown)==0) digitsLock=true;

if (digitalRead(pinUp)==0) digitsLock=false;

if ((millis()-startOfTest)>dlay)

{

startOfTest=millis();

if (!digitsLock) strIndex=strIndex+1;

if (strIndex==10) dlay=2000;

if (strIndex>10) { test=false; strIndex=10;}

stringToDisplay=testStringArray[strIndex];

#ifdef DEBUG

Serial.println(stringToDisplay);

#endif

}

#if defined (__AVR_ATmega328P__)

doIndication();

#endif

}

if ( !ds.search(addr))

{

#ifdef DEBUG

Serial.println(F(“Temp. sensor not found.”));

#endif

} else TempPresent=true;

testDS3231TempSensor();

#ifdef DEBUG

Serial.println(F(“Stop Test”));

#endif

// while(1);

}

void doDotBlink()

{

if (second()%2 == 0) dotPattern = B11000000;

else dotPattern = B00000000;

}

void setRTCDateTime(byte h, byte m, byte s, byte d, byte mon, byte y, byte w)

{

Wire.beginTransmission(DS1307_ADDRESS);

Wire.write(zero); //stop Oscillator

Wire.write(decToBcd(s));

Wire.write(decToBcd(m));

Wire.write(decToBcd(h));

Wire.write(decToBcd(w));

Wire.write(decToBcd(d));

Wire.write(decToBcd(mon));

Wire.write(decToBcd(y));

Wire.write(zero); //start

Wire.endTransmission();

}

byte decToBcd(byte val) {

// Convert normal decimal numbers to binary coded decimal

return ( (val / 10 * 16) + (val % 10) );

}

byte bcdToDec(byte val) {

// Convert binary coded decimal to normal decimal numbers

return ( (val / 16 * 10) + (val % 16) );

}

void getRTCTime()

{

Wire.beginTransmission(DS1307_ADDRESS);

Wire.write(zero);

Wire.endTransmission();

Wire.requestFrom(DS1307_ADDRESS, 7);

RTC_seconds = bcdToDec(Wire.read());

RTC_minutes = bcdToDec(Wire.read());

RTC_hours = bcdToDec(Wire.read() & 0b111111); //24 hour time

RTC_day_of_week = bcdToDec(Wire.read()); //0-6 -> sunday – Saturday

RTC_day = bcdToDec(Wire.read());

RTC_month = bcdToDec(Wire.read());

RTC_year = bcdToDec(Wire.read());

}

int extractDigits(byte b)

{

String tmp = “1”;

if (b == B00000011)

{

tmp = stringToDisplay.substring(0, 2);

}

if (b == B00001100)

{

tmp = stringToDisplay.substring(2, 4);

}

if (b == B00110000)

{

tmp = stringToDisplay.substring(4);

}

return tmp.toInt();

}

void injectDigits(byte b, int value)

{

if (b == B00000011) stringToDisplay = PreZero(value) + stringToDisplay.substring(2);

if (b == B00001100) stringToDisplay = stringToDisplay.substring(0, 2) + PreZero(value) + stringToDisplay.substring(4);

if (b == B00110000) stringToDisplay = stringToDisplay.substring(0, 4) + PreZero(value);

}

bool isValidDate()

{

int days[12] = {31, 28, 31, 30, 31, 30, 31, 31, 30, 31, 30, 31};

if (value[DateYearIndex] % 4 == 0) days[1] = 29;

if (value[DateDayIndex] > days[value[DateMonthIndex] – 1]) return false;

else return true;

}

byte default_dur = 4;

byte default_oct = 6;

int bpm = 63;

int num;

long wholenote;

long duration;

byte note;

byte scale;

char* parseSong(char *p)

{

// Absolutely no error checking in here

// format: d=N,o=N,b=NNN:

// find the start (skip name, etc)

while (*p != ‘:’) p++; // ignore name

p++; // skip ‘:’

// get default duration

if (*p == ‘d’)

{

p++; p++; // skip “d=”

num = 0;

while (isdigit(*p))

{

num = (num * 10) + (*p++ – ‘0’);

}

if (num > 0) default_dur = num;

p++; // skip comma

}

// get default octave

if (*p == ‘o’)

{

p++; p++; // skip “o=”

num = *p++ – ‘0’;

if (num >= 3 && num <= 7) default_oct = num;

p++; // skip comma

}

// get BPM

if (*p == ‘b’)

{

p++; p++; // skip “b=”

num = 0;

while (isdigit(*p))

{

num = (num * 10) + (*p++ – ‘0’);

}

bpm = num;

p++; // skip colon

}

// BPM usually expresses the number of quarter notes per minute

wholenote = (60 * 1000L / bpm) * 4; // this is the time for whole note (in milliseconds)

return p;

}

// now begin note loop

static unsigned long lastTimeNotePlaying = 0;

char* playmusic(char *p)

{

if (*p == 0)

{

return p;

}

if (millis() – lastTimeNotePlaying > duration)

lastTimeNotePlaying = millis();

else return p;

// first, get note duration, if available

num = 0;

while (isdigit(*p))

{

num = (num * 10) + (*p++ – ‘0’);

}

if (num) duration = wholenote / num;

else duration = wholenote / default_dur; // we will need to check if we are a dotted note after

// now get the note

note = 0;

switch (*p)

{

case ‘c’:

note = 1;

break;

case ‘d’:

note = 3;

break;

case ‘e’:

note = 5;

break;

case ‘f’:

note = 6;

break;

case ‘g’:

note = 8;

break;

case ‘a’:

note = 10;

break;

case ‘b’:

note = 12;

break;

case ‘p’:

default:

note = 0;

}

p++;

// now, get optional ‘#’ sharp

if (*p == ‘#’)

{

note++;

p++;

}

// now, get optional ‘.’ dotted note

if (*p == ‘.’)

{

duration += duration / 2;

p++;

}

// now, get scale

if (isdigit(*p))

{

scale = *p – ‘0’;

p++;

}

else

{

scale = default_oct;

}

scale += OCTAVE_OFFSET;

if (*p == ‘,’)

p++; // skip comma for next note (or we may be at the end)

// now play the note

if (note)

{

tone1.play(notes[(scale – 4) * 12 + note], duration);

if (millis() – lastTimeNotePlaying > duration)

lastTimeNotePlaying = millis();

else return p;

tone1.stop();

}

else

{

return p;

}

#ifdef DEBUG

Serial.println(F(“Incorrect Song Format!”));

#endif

return 0; //error

}

void incrementValue()

{

enteringEditModeTime = millis();

if (editMode == true)

{

if (menuPosition != hModeValueIndex) // 12/24 hour mode menu position

value[menuPosition] = value[menuPosition] + 1; else value[menuPosition] = value[menuPosition] + 12;

if (value[menuPosition] > maxValue[menuPosition]) value[menuPosition] = minValue[menuPosition];

if (menuPosition == Alarm01)

{

if (value[menuPosition] == 1) /*digitalWrite(pinUpperDots, HIGH);*/dotPattern = B10000000; //turn on upper dots

/*else digitalWrite(pinUpperDots, LOW); */ dotPattern = B00000000; //turn off all dots

}

if (menuPosition!=DateFormatIndex) injectDigits(blinkMask, value[menuPosition]);

/*Serial.print(“value=”);

Serial.println(value[menuPosition]);*/

}

}

void dicrementValue()

{

enteringEditModeTime = millis();

if (editMode == true)

{

if (menuPosition != hModeValueIndex) value[menuPosition] = value[menuPosition] – 1; else value[menuPosition] = value[menuPosition] – 12;

if (value[menuPosition] < minValue[menuPosition]) value[menuPosition] = maxValue[menuPosition];

if (menuPosition == Alarm01)

{

if (value[menuPosition] == 1) /*digitalWrite(pinUpperDots, HIGH);*/ dotPattern = B10000000; //turn on upper dots

else /*digitalWrite(pinUpperDots, LOW);*/ dotPattern = B00000000; //turn off all dots

}

if (menuPosition!=DateFormatIndex) injectDigits(blinkMask, value[menuPosition]);

/*Serial.print(“value=”);

Serial.println(value[menuPosition]);*/

}

}

bool Alarm1SecondBlock = false;

unsigned long lastTimeAlarmTriggired = 0;

void checkAlarmTime()

{

if (value[Alarm01] == 0) return;

if ((Alarm1SecondBlock == true) && ((millis() – lastTimeAlarmTriggired) > 1000)) Alarm1SecondBlock = false;

if (Alarm1SecondBlock == true) return;

if ((hour() == value[AlarmHourIndex]) && (minute() == value[AlarmMinuteIndex]) && (second() == value[AlarmSecondIndex]))

{

lastTimeAlarmTriggired = millis();

Alarm1SecondBlock = true;

#ifdef DEBUG

Serial.println(F(“Wake up, Neo!”));

#endif

p = song;

}

}

void modesChanger()

{

if (editMode == true) return;

static unsigned long lastTimeModeChanged = millis();

static unsigned long lastTimeAntiPoisoningIterate = millis();

static int transnumber = 0;

if ((millis() – lastTimeModeChanged) > modesChangePeriod)

{

lastTimeModeChanged = millis();

if (transnumber == 0) {

menuPosition = DateIndex;

modesChangePeriod = dateModePeriod;

}

if (transnumber == 1) {

menuPosition = TemperatureIndex;

modesChangePeriod = dateModePeriod;

if (!TempPresent) transnumber = 2;

}

if (transnumber == 2) {

menuPosition = TimeIndex;

modesChangePeriod = timeModePeriod;

}

transnumber++;

if (transnumber > 2) transnumber = 0;

if (modeChangedByUser == true)

{

menuPosition = TimeIndex;

}

modeChangedByUser = false;

}

if ((millis() – lastTimeModeChanged) < 2000)

{

if ((millis() – lastTimeAntiPoisoningIterate) > 100)

{

lastTimeAntiPoisoningIterate = millis();

if (TempPresent)

{

if (menuPosition == TimeIndex) stringToDisplay = antiPoisoning2(updateTemperatureString(getTemperature(value[DegreesFormatIndex])), getTimeNow());

if (menuPosition == DateIndex) stringToDisplay = antiPoisoning2(getTimeNow(), PreZero(day()) + PreZero(month()) + PreZero(year() % 1000) );

if (menuPosition == TemperatureIndex) stringToDisplay = antiPoisoning2(PreZero(day()) + PreZero(month()) + PreZero(year() % 1000), updateTemperatureString(getTemperature(value[DegreesFormatIndex])));

} else

{

if (menuPosition == TimeIndex) stringToDisplay = antiPoisoning2(PreZero(day()) + PreZero(month()) + PreZero(year() % 1000), getTimeNow());

if (menuPosition == DateIndex) stringToDisplay = antiPoisoning2(getTimeNow(), PreZero(day()) + PreZero(month()) + PreZero(year() % 1000) );

}

// Serial.println(“StrTDInToModeChng=”+stringToDisplay);

}

} else

{

transactionInProgress = false;

}

}

String antiPoisoning2(String fromStr, String toStr)

{

//static bool transactionInProgress=false;

//byte fromDigits[6];

static byte toDigits[6];

static byte currentDigits[6];

static byte iterationCounter = 0;

if (!transactionInProgress)

{

transactionInProgress = true;

blankMask = B00000000;

for (int i = 0; i < 6; i++)

{

currentDigits[i] = fromStr.substring(i, i + 1).toInt();

toDigits[i] = toStr.substring(i, i + 1).toInt();

}

}

for (int i = 0; i < 6; i++)

{

if (iterationCounter < 10) currentDigits[i]++;

else if (currentDigits[i] != toDigits[i]) currentDigits[i]++;

if (currentDigits[i] == 10) currentDigits[i] = 0;

}

iterationCounter++;

if (iterationCounter == 20)

{

iterationCounter = 0;

transactionInProgress = false;

}

String tmpStr;

for (int i = 0; i < 6; i++)

tmpStr += currentDigits[i];

return tmpStr;

}

String updateDateString()

{

static unsigned long lastTimeDateUpdate = millis()+1001;

static String DateString = PreZero(day()) + PreZero(month()) + PreZero(year() % 1000);

static byte prevoiusDateFormatWas=value[DateFormatIndex];

if (((millis() – lastTimeDateUpdate) > 1000) || (prevoiusDateFormatWas != value[DateFormatIndex]))

{

lastTimeDateUpdate = millis();

if (value[DateFormatIndex]==EU_DateFormat) DateString = PreZero(day()) + PreZero(month()) + PreZero(year() % 1000);

else DateString = PreZero(month()) + PreZero(day()) + PreZero(year() % 1000);

}

return DateString;

}

#if defined(__AVR_ATmega1280__) || defined(__AVR_ATmega2560__)

void SyncWithGPS()

{

if ((millis() – GPS_Date_Time.GPS_Data_Parsed_time) > 3000) {

Serial.println(F(“Parsed data to old”));

return;

}

Serial.println(F(“Updating time from GPS…”));

Serial.println(GPS_Date_Time.GPS_hours);

Serial.println(GPS_Date_Time.GPS_minutes);

Serial.println(GPS_Date_Time.GPS_seconds);

setTime(GPS_Date_Time.GPS_hours, GPS_Date_Time.GPS_minutes, GPS_Date_Time.GPS_seconds, GPS_Date_Time.GPS_day, GPS_Date_Time.GPS_mounth, GPS_Date_Time.GPS_year % 1000);

adjustTime((long)value[HoursOffsetIndex] * 3600);

setRTCDateTime(hour(), minute(), second(), day(), month(), year() % 1000, 1);

Last_Time_GPS_Sync = MillsNow;

GPS_Sync_Interval = GPS_SYNC_INTERVAL;

AttMsgWasShowed=false;

//// TIMEZONE add-ons

while (!Serial) ; // wait until Arduino Serial Monitor opens

//setSyncProvider(RTC.get); // the function to get the time from the RTC

//if(timeStatus()!= timeSet)

// Serial.println(“Unable to sync with the RTC”);

//else

// Serial.println(“RTC has set the system time”);

time_t utc = now();

time_t local = myTZ.toLocal(utc, &tcr);

Serial.println();

printDateTime(utc, “UTC”);

printDateTime(local, tcr -> abbrev);

setTime(myTZ.toLocal(utc, &tcr));

EEPROM.write(DateFormatEEPROMAddress, value[myTZ.toLocal(utc, &tcr)]);

//Serial.println(EEPROM.read(HourFormatEEPROMAddress));// check whether the new timezon’s winter /summer time is put in memory

//setTime(hour(), minute(), second(), value[DateDayIndex], value[DateMonthIndex], 2000 + value[DateYearIndex]);

//EEPROM.write(DateFormatEEPROMAddress, value[DateFormatIndex]);

//// End of TIMEZONE add-ons

}

void GetDataFromSerial1()

{

if (Serial1.available()) { // If anything comes in Serial1 (pin 19)

byte GPS_incoming_byte;

GPS_incoming_byte = Serial1.read();

//Serial.write(GPS_incoming_byte);

GPS_Package[GPS_position] = GPS_incoming_byte;

GPS_position++;

if (GPS_position == GPS_BUFFER_LENGTH – 1)

{

GPS_position = 0;

// Serial.println(“more then BUFFER_LENGTH!!!!”);

}

if (GPS_incoming_byte == 0x0A)

{

GPS_Package[GPS_position] = 0;

GPS_position = 0;

if (ControlCheckSum()) {

if (GPS_Parse_DateTime()) SyncWithGPS();

}

}

}

}

bool GPS_Parse_DateTime()

{

bool GPSsignal = false;

if (!((GPS_Package[0] == ‘$’)

&& (GPS_Package[3] == ‘R’)

&& (GPS_Package[4] == ‘M’)

&& (GPS_Package[5] == ‘C’))) {

return false;

}

else

{

// Serial.println(“RMC!!!”);

}

//Serial.print(“hh: “);

int hh = (GPS_Package[7] – 48) * 10 + GPS_Package[8] – 48;

//Serial.println(hh);

int mm = (GPS_Package[9] – 48) * 10 + GPS_Package[10] – 48;

//Serial.print(“mm: “);

//Serial.println(mm);

int ss = (GPS_Package[11] – 48) * 10 + GPS_Package[12] – 48;

//Serial.print(“ss: “);

//Serial.println(ss);

byte GPSDatePos = 0;

int CommasCounter = 0;

for (int i = 12; i < GPS_BUFFER_LENGTH ; i++)

{

if (GPS_Package[i] == ‘,’)

{

CommasCounter++;

if (CommasCounter == 8)

{

GPSDatePos = i + 1;

break;

}

}

}

//Serial.print(“dd: “);

int dd = (GPS_Package[GPSDatePos] – 48) * 10 + GPS_Package[GPSDatePos + 1] – 48;

//Serial.println(dd);

int MM = (GPS_Package[GPSDatePos + 2] – 48) * 10 + GPS_Package[GPSDatePos + 3] – 48;

//Serial.print(“MM: “);

//Serial.println(MM);

int yyyy = 2000 + (GPS_Package[GPSDatePos + 4] – 48) * 10 + GPS_Package[GPSDatePos + 5] – 48;

//Serial.print(“yyyy: “);

//Serial.println(yyyy);

//if ((hh<0) || (mm<0) || (ss<0) || (dd<0) || (MM<0) || (yyyy<0)) return false;

if ( !inRange( yyyy, 2018, 2038 ) ||

!inRange( MM, 1, 12 ) ||

!inRange( dd, 1, 31 ) ||

!inRange( hh, 0, 23 ) ||

!inRange( mm, 0, 59 ) ||

!inRange( ss, 0, 59 ) ) return false;

else

{

GPS_Date_Time.GPS_hours = hh;

GPS_Date_Time.GPS_minutes = mm;

GPS_Date_Time.GPS_seconds = ss;

GPS_Date_Time.GPS_day = dd;

GPS_Date_Time.GPS_mounth = MM;

GPS_Date_Time.GPS_year = yyyy;

GPS_Date_Time.GPS_Data_Parsed_time = millis();

//Serial.println(“Precision TIME HAS BEEN ACCURED!!!!!!!!!”);

//GPS_Package[0]=0x0A;

return 1;

}

}

uint8_t ControlCheckSum()

{

uint8_t CheckSum = 0, MessageCheckSum = 0; // check sum

uint16_t i = 1; // 1 sybol left from ‘$’

while (GPS_Package[i] != ‘*’)

{

CheckSum ^= GPS_Package[i];

if (++i == GPS_BUFFER_LENGTH) {

//Serial.println(F(“End of the line not found”)); // end of line not found

return 0;

}

}

if (GPS_Package[++i] > 0x40) MessageCheckSum = (GPS_Package[i] – 0x37) << 4; // ASCII codes to DEC convertation

else MessageCheckSum = (GPS_Package[i] – 0x30) << 4;

if (GPS_Package[++i] > 0x40) MessageCheckSum += (GPS_Package[i] – 0x37);

else MessageCheckSum += (GPS_Package[i] – 0x30);

if (MessageCheckSum != CheckSum) {

//Serial.println(F(“wrong checksum”)); // wrong checksum

return 0;

}

//Serial.println(“Checksum is ok”);

return 1; // all ok!

}

boolean inRange( int no, int low, int high )

{

if ( no < low || no > high )

{

Serial.println(F(“Date or Time not in range”));

//Serial.println(String(no) + “:” + String (low) + “-” + String(high));

return false;

}

return true;

}

#endif

String updateTemperatureString(float fDegrees)

{

static unsigned long lastTimeTemperatureString=millis()+1100;

static String strTemp =”000000″;

if ((millis() – lastTimeTemperatureString) > 1000)

{

//Serial.println(F(“Updating temp. str.”));

lastTimeTemperatureString = millis();

int iDegrees = round(fDegrees);

if (value[DegreesFormatIndex] == CELSIUS)

{

strTemp = “0” + String(abs(iDegrees)) + “0”;

if (abs(iDegrees) < 1000) strTemp = “00” + String(abs(iDegrees)) + “0”;

if (abs(iDegrees) < 100) strTemp = “000” + String(abs(iDegrees)) + “0”;

if (abs(iDegrees) < 10) strTemp = “0000” + String(abs(iDegrees)) + “0”;

}else

{

strTemp = “0” + String(abs(iDegrees)) + “0”;

if (abs(iDegrees) < 1000) strTemp = “00” + String(abs(iDegrees)/10) + “00”;

if (abs(iDegrees) < 100) strTemp = “000” + String(abs(iDegrees)/10) + “00”;

if (abs(iDegrees) < 10) strTemp = “0000” + String(abs(iDegrees)/10) + “00”;

}

#ifdef tubes8

strTemp= “”+strTemp+”00”;

#endif

return strTemp;

}

return strTemp;

}

float getTemperature (boolean bTempFormat)

{

static float fDegrees;

static int iterator=0;

static byte TempRawData[2];

/*unsigned long execTime=0;

execTime=micros();*/

switch (iterator)

{

case 0: ds.reset(); break;

case 1: ds.write(0xCC, 0); break; //skip ROM command

case 2: ds.write(0x44, 0); break; //send make convert to all devices

case 3: ds.reset(); break;

case 4: ds.write(0xCC, 0); break; //skip ROM command

case 5: ds.write(0xBE, 0); break; //send request to all devices

case 6: TempRawData[0] = ds.read(); break;

case 7: TempRawData[1] = ds.read(); break;

default: break;

}

if (iterator == 7)

{

int16_t raw = (TempRawData[1] << 8) | TempRawData[0];

if (raw == -1) raw = 0;

float celsius = (float)raw / 16.0;

//celsius = celsius + (float)value[TempAdjustIndex]/10;//users adjustment

if (!bTempFormat) fDegrees = celsius * 10;

else fDegrees = (celsius * 1.8 + 32.0) * 10;

}

/*execTime=micros()-execTime;

Serial.print(iterator);

Serial.println(execTime);*/

iterator++;

if (iterator==8) iterator=0;

return fDegrees;

}

#if defined(__AVR_ATmega1280__) || defined(__AVR_ATmega2560__)

ISR(TIMER4_COMPA_vect)

{

sei();

doIndication();

}

void timerSetup()

{

//timer3 setup for calling doIndication function

TCCR4A = 0; //control registers reset (WGM21, WGM20)

TCCR4B = 0; //control registers reset

TCCR4B = (1 << CS12)|(1 << CS10)|(1 << WGM12); //prescaler 1024 and CTC mode

//OCR5A = 31; //2 mS

TCNT4=0; //reset counter to 0

OCR4A = 46; //3mS

//OCR4A = 92; //6mS

TIMSK4 = (1 << OCIE1A);//TIMER3_COMPA_vect interrupt enable

sei();

}

#endif

void testDS3231TempSensor()

{

int8_t DS3231InternalTemperature=0;

Wire.beginTransmission(DS1307_ADDRESS);

Wire.write(0x11);

Wire.endTransmission();

Wire.requestFrom(DS1307_ADDRESS, 2);

DS3231InternalTemperature=Wire.read();

Serial.print(F(“DS3231_T=”));

Serial.println(DS3231InternalTemperature);

if ((DS3231InternalTemperature<5) || (DS3231InternalTemperature>60))

{

Serial.println(F(“Faulty DS3231!”));

for (int i=0; i<5; i++)

{

tone1.play(1000, 1000);

delay(2000);

}

}

}

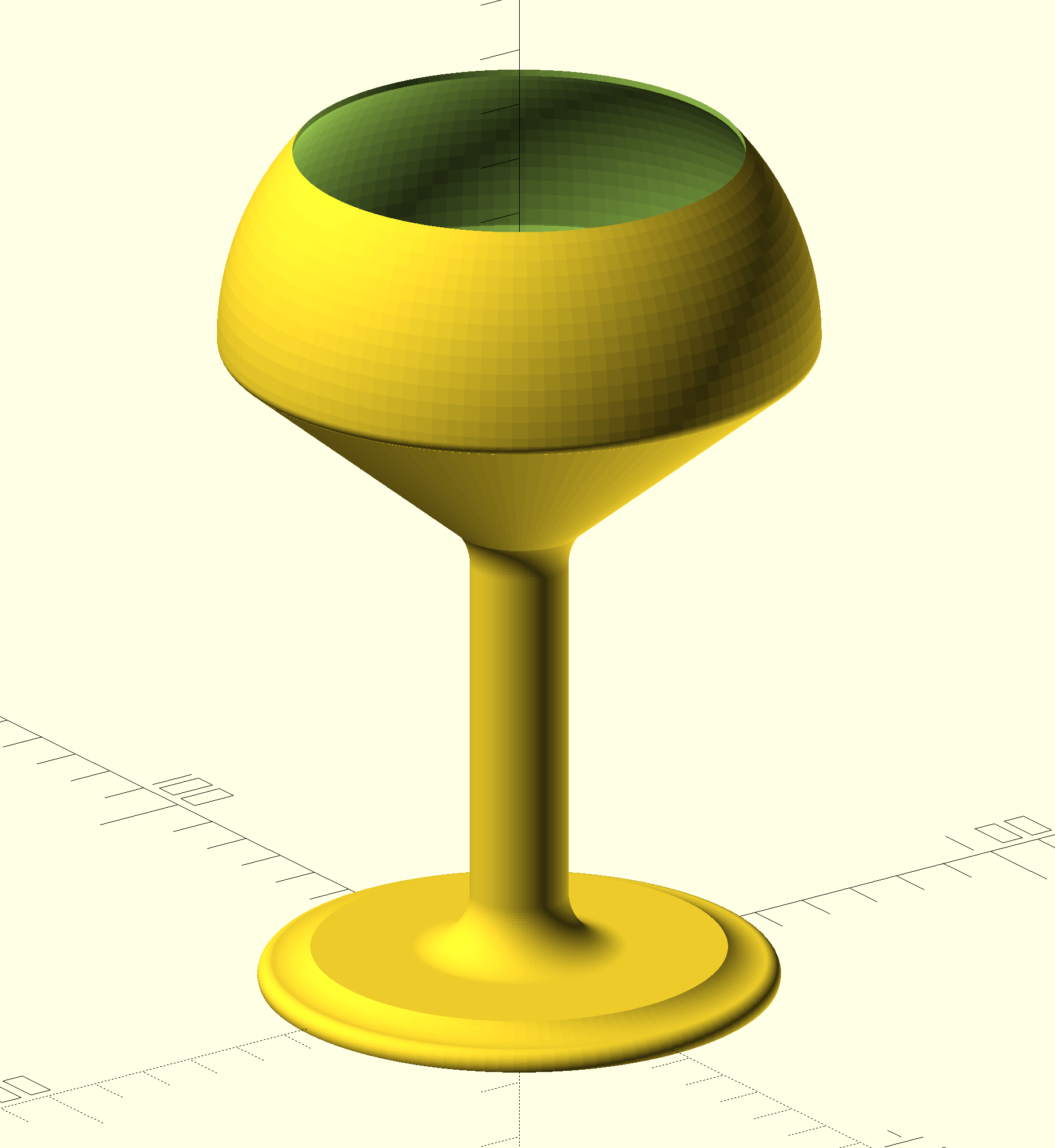

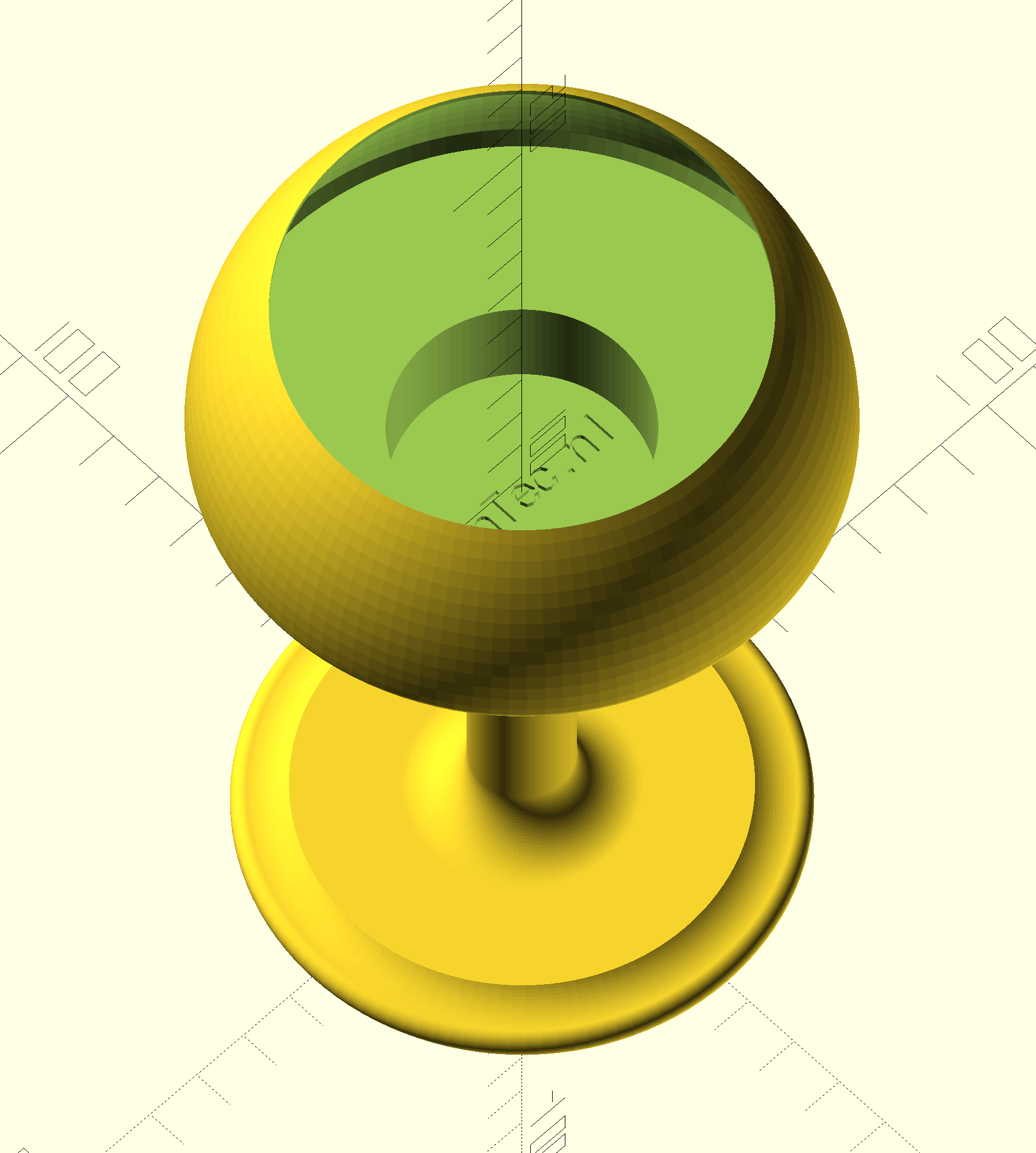

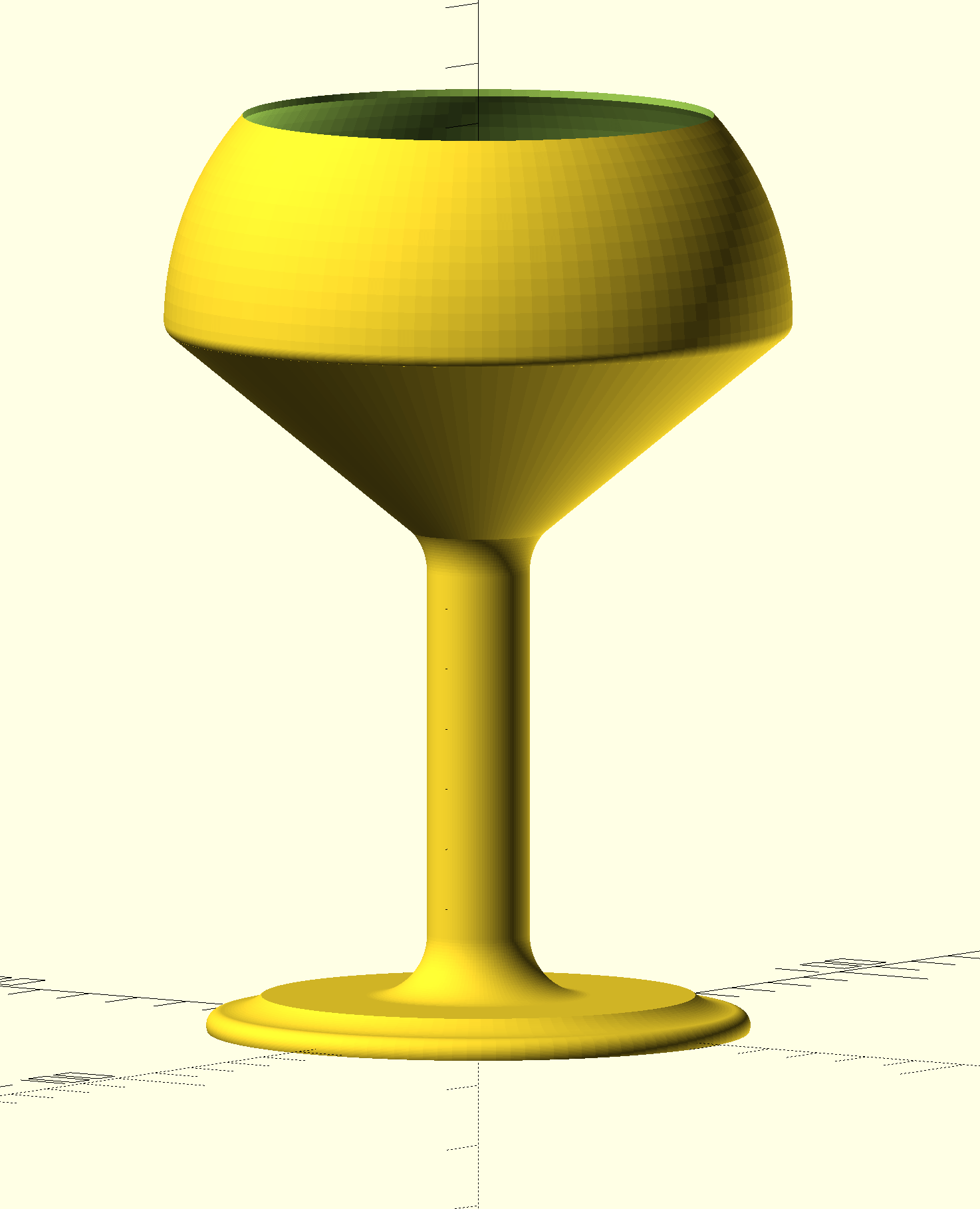

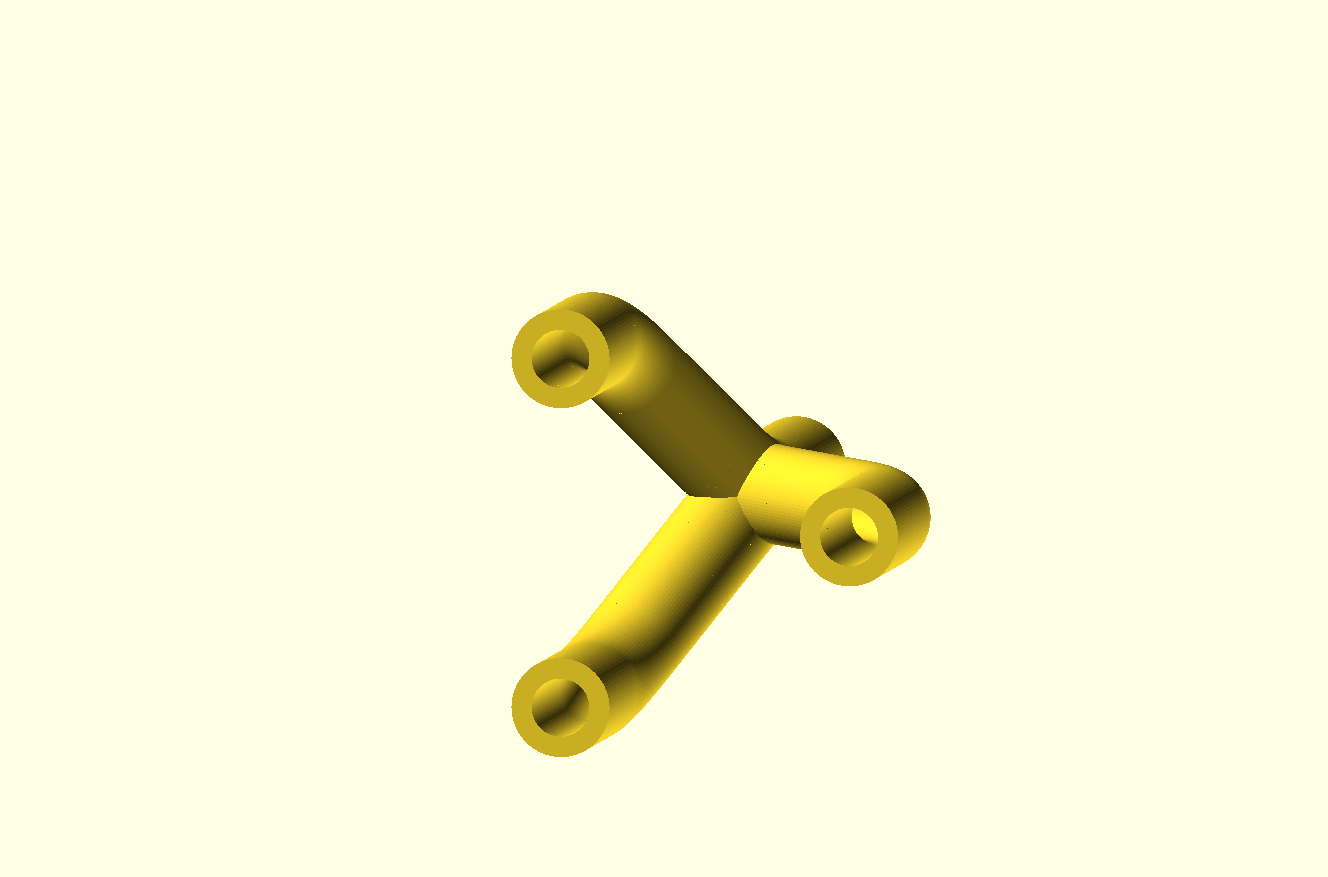

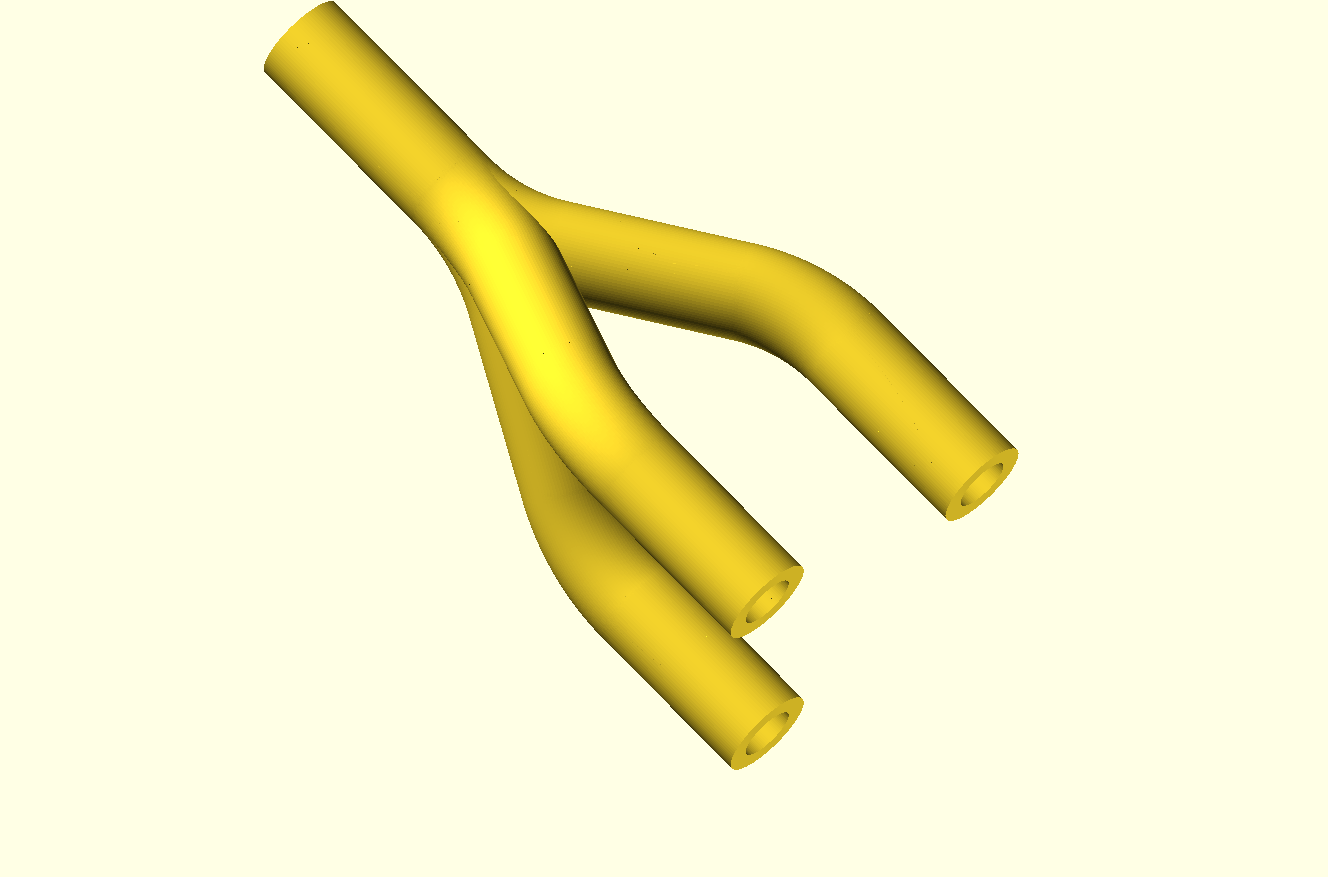

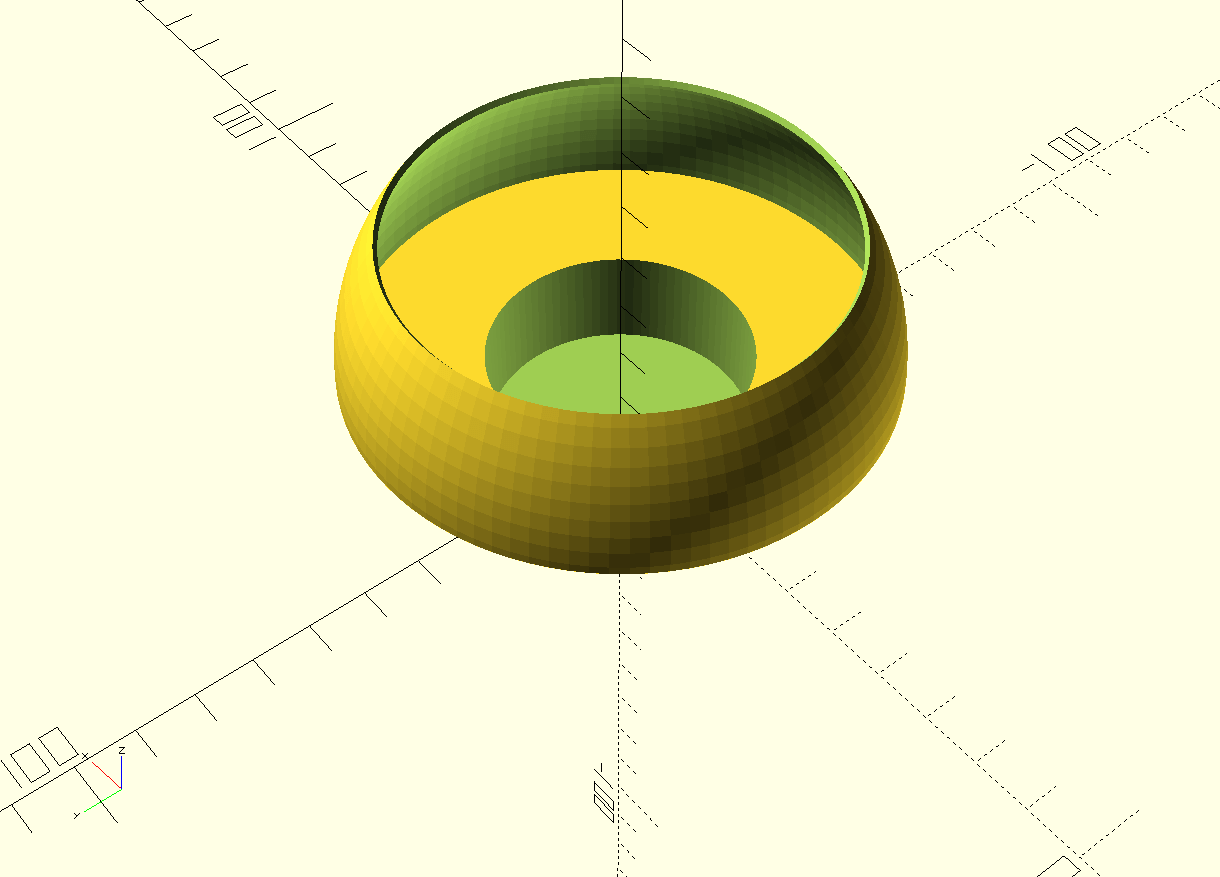

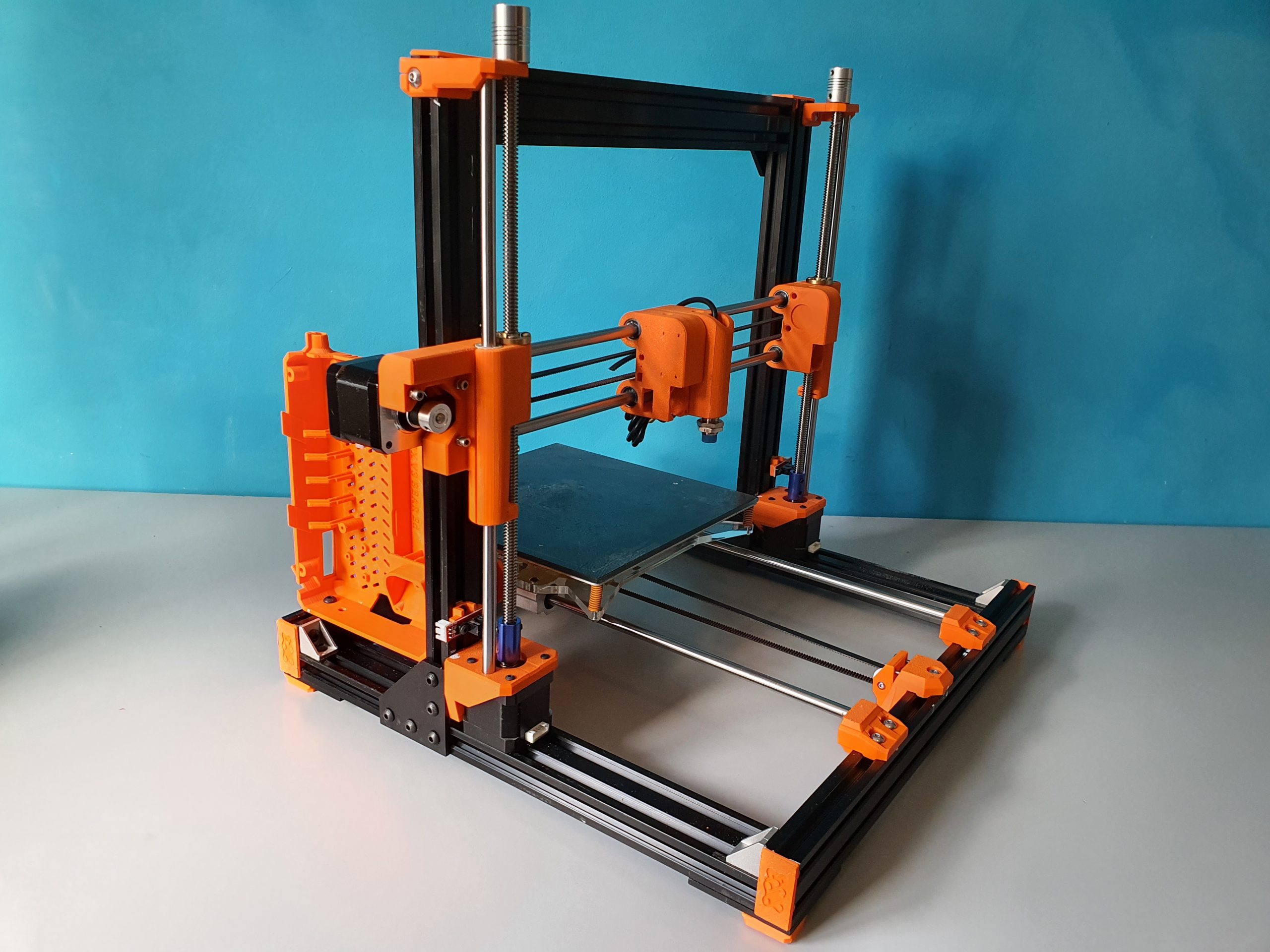

Tow bar ball cover 2-23 05 11 V1 Reve facet shaped FREE DOWNLOAD

Tow bar ball cover 2-23 05 11 V1 Reve facet shaped FREE DOWNLOAD